Problem

Possible Cause

Correction

Ice machine does

not cycle into

harvest mode.

Harvest float switch

is dirty.

Descale and sanitize the ice

machine.

Harvest float switch

wire is disconnected.

Connect the wire

Harvest float switch is

out of adjustment.

Adjust the harvest float

switch.

Uneven ice fill (thin at

top of evaporator).

Refer to “Shallow or

Incomplete Cubes”

Ice quality

is poor

Poor incoming water

quality.

Test the quality of the

incoming water and

make appropriate filter

recommendations.

Water filtration is poor.

Replace the filter.

Ice machine is dirty.

Descale and sanitize the ice

machine.

Ice machine

produces shallow

or incomplete

cubes, or the ice

fill pattern on

the evaporator is

incomplete.

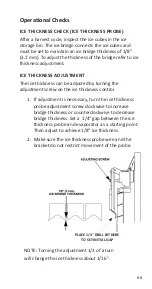

Ice thickness float is

out of adjustment.

Adjust the ice

thickness float

Water level is

too low.

Check the water float.

Water filtration is poor.

Replace the filter.

Hot incoming water.

Connect the ice machine to

a cold water supply.

Incorrect incoming

water pressure.

Water pressure must be 20-

80 psi (137.9 -551.5 kPa)

Ice machine is not level.

Level the ice machine

Low ice capacity.

The condenser is dirty.

Clean the condenser.

High air temperature

around ice machine

(air-cooled models).

Air temperature must

not exceed 100° F (43°C).

Inadequate clearance

around the ice

machine.

Provide adequate clearance

Objects stacked around

ice machine, blocking

condenser airflow

Remove items blocking

airflow

Hot incoming water.

Connect to cold water

Incorrect incoming

water pressure. Water

pressure is too low or

water filter is restricted.

Water pressure must be 20-

80 psi (137.9 -551.5 kPa).

Replace water filter.

Ice thickness probe out

of adjustment or dirty

Adjust or clean the ice

thickness probe.

Ice thickness probe

out of adjustment or

dirty

Adjust or clean the ice

thickness probe.

76

Summary of Contents for IC-0170A

Page 1: ...Undercounter Ice Machines Technician s Handbook Revision Date 1 24 22...

Page 2: ......

Page 14: ...THIS PAGE INTENTIONALLY LEFT BLANK...

Page 17: ...16 How to Read a Serial Number Full Serial Number...

Page 154: ...WU 0100 WIRING DIAGRAM Self Contained Air cooled 153...

Page 155: ...IC 0170 IU 0170 IC 0220 IU 0220 WIRING DIAGRAM Self Contained Air cooled 154...

Page 156: ...Printed Circuit Bards PCB WU 0100 PCB 155...

Page 161: ...SPACE FOR TECHNICIAN S NOTES...

Page 162: ...SPACE FOR TECHNICIAN S NOTES...

Page 163: ...SPACE FOR TECHNICIAN S NOTES...

Page 164: ...SPACE FOR TECHNICIAN S NOTES...

Page 165: ......