10

ICE i20NB / i20NBT / i20NBT-OB / i24BT

OPERATOR MANUAL

daIly maIntenance

1. Remove pad driver/ brush and clean with

approved cleaner.

2. Drain recovery and solution tanks completely

and rinse out with clean water. Visually check

the recovery tank for debris and clean out as

necessary.

3.

Raise the squeegee assembly off floor and wipe

it down with a damp towel. Be sure to store the

squeegee in the up position.

4.

Remove the float shut-off assembly and rinse it

out with clean water.

5. Clean machine with an approved cleaner and a

damp towel.

6. Recharge the batteries.

7. Check the condition of the squeegee blade

wiping edge, rotate blade if worn.

montHly maIntenance

1. Clean the battery tops to prevent corrosion.

2. Check for loose battery cable connections.

3. Inspect and clean the recovery tank cover seal.

Replce it if damaged.

4. Lubricate all grease points and pivot points with

silicon spray and approved grease.

5. Check the machine for loose nuts and bolts.

6. Check the machine for leaks.

oRBItal Head maIntenance

For Orbital head, you should have checked the

eight isolators located in the Orbital head every

300 hours.

1.

Using a flashlight, do a visual inspection of the

isolators by looking through the opening in the

Orbital head and checking for wear or damage

to four isolators in the front and four in the

rear of the Orbital head. The locations of the

isolators are show below.

2. If any of the eight isolators show signs of wear,

degradation or damage, contact your lacal

distributor to replace all eight isolators.

motoR maIntenance

1. Contact your local Distributor for any motor

maintenance.

2. Motor should have the brushes checked every

250 hours. Brushes should be replaced when

they are worn to a length of 10 mm or less.

BatteRy maIntenance

WaRnInG: Batteries emit hydrogen gas

and an explosion o fire can result. Keep sparks

and fire away from batteries at all times.

WARNING: Whenever serviving batteries,

be sure to wear protective gloves. Avoid

contact with battery acid at all times.

NOTE:

For the best machine performance, keep

batteries charged at all times. Do not let them sit in

a discharged condition.

1. Always follow the battery charging directions as

outlined in the BATTERY CHARGING section of

this manual.

2. Keep battery tops and terminals free from

corrosion. A strong solution of baking soda

and water is the best way to keep the batteries

corrosion free. DO NOT ALLOW THE BAKING

SODA / WATER SOLUTION TO ENTER THE

BATTERY CELLS.

3. Use a wire brush with the baking soda solution

to properly clean the battery posts and

connctions.

4. Check battery connections for wear and loose

terminals. replace if necessary.

macHIne StoRaGe

1. Always store the machine indoors.

2. Always store the machine in a dry area.

3. Always store the machine in its upright position.

4. Always store the machine with the pad driver/

brush raised off the floor.

5. Always store the machine with the squeegee

assembly raised off the floor.

6. If storing in an area which may reach freezing

temperatures, be sure to drain all fluids from the

machine prior to storage. Any damage caused

by freezing temperatures will not be covered by

the warranty.

7. Drain the recovery tank.

8.

Drain the solution tank of all fluid.

Summary of Contents for i20NB

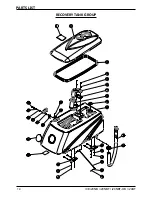

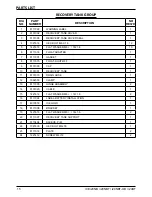

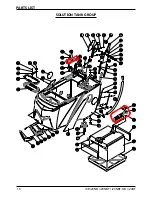

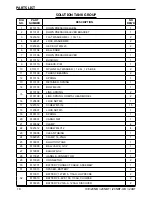

Page 14: ...14 ICE i20NB i20NBT i20NBT OB i24BT PARTS LIST RECOVERY TANK GROUP...

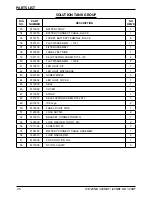

Page 16: ...16 ICE i20NB i20NBT i20NBT OB i24BT PARTS LIST VACUUM FAN GROUP...

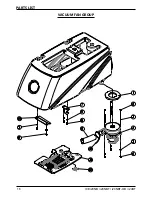

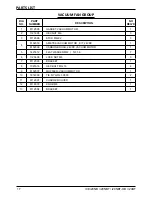

Page 18: ...18 ICE i20NB i20NBT i20NBT OB i24BT PARTS LIST SOLUTION TANK GROUP...

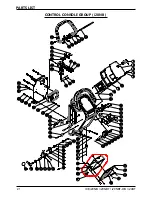

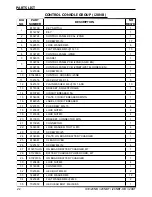

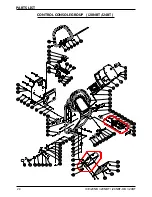

Page 21: ...21 ICE i20NB i20NBT i20NBT OB i24BT PARTS LIST CONTROL CONSOLE GROUP i20NB...

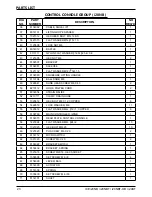

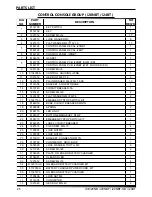

Page 24: ...24 ICE i20NB i20NBT i20NBT OB i24BT PARTS LIST CONTROL CONSOLE GROUP i20NBT i24BT...

Page 27: ...27 ICE i20NB i20NBT i20NBT OB i24BT PARTS LIST FRAME WHEEL GROUP i20NB...

Page 29: ...29 ICE i20NB i20NBT i20NBT OB i24BT PARTS LIST FRAME TRANSAXLE GROUP i20NBT i24BT...

Page 31: ...31 ICE i20NB i20NBT i20NBT OB i24BT PARTS LIST SCRUB HEAD GROUP i20NB i20NBT...

Page 33: ...33 ICE i20NB i20NBT i20NBT OB i24BT PARTS LIST ORBITAL HEAD GROUP i20NBT OB...

Page 35: ...35 ICE i20NB i20NBT i20NBT OB i24BT PARTS LIST SCRUB HEAD GROUP i24BT...

Page 37: ...37 ICE i20NB i20NBT i20NBT OB i24BT PARTS LIST SCRUB HEAD LIFT GROUP i20NB i20NBT...

Page 39: ...39 ICE i20NB i20NBT i20NBT OB i24BT PARTS LIST ORBITAL HEAD LIFT GROUP i20NBT OB...

Page 41: ...41 ICE i20NB i20NBT i20NBT OB i24BT PARTS LIST SCRUB HEAD LIFT GROUP i24BT...

Page 43: ...43 ICE i20NB i20NBT i20NBT OB i24BT PARTS LIST SQUEEGEE GROUP...

Page 45: ...45 ICE i20NB i20NBT i20NBT OB i24BT PARTS LIST SOLUTION GROUP...