Remote Condenser

Remote Refrigeration System

Page 7

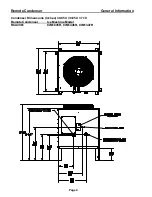

The Remote Refrigeration System is shown in the above diagram. During the freezing cycle, high

temperature and high pressure liquid refrigerant is directed from the condenser through a mixing valve,

receiver, liquid line solenoid heat exchanger and a filter drier. The expansion valve meters refrigerant to the

coils on the back of the evaporator.

In low ambient conditions (below 70

F air temperature at the condenser) the mixing valve opens to mix

discharge gas with liquid returning from the condenser, in the receiver, to maintain discharge and liquid line

pressures.

The low temperature and pressure refrigerant leaving the evaporator is directed through the suction line

heat exchanger and is returned to the compressor. There it is compressed to a high temperature and high

pressure gas. It is then directed to a condenser to be converted again to a high temperature and high

pressure liquid.

During the harvest cycle, the hot gas solenoid valve (normally closed during the freeze cycle), opens and

directs the high temperature gas leaving the compressor into the evaporator. Once the evaporator has

reached approximately 40

F, the harvest motor overcomes the capillary attraction of the ice and the

evaporator releases the ice. At the end of the harvest cycle, the hot gas solenoid valve closes and another

freeze cycle begins.

During the off cycle, the liquid line solenoid valve closes.

Summary of Contents for RCA1001

Page 2: ......