Flake Ice Machines

Refrigeration System

Page

F10

Remote System

Machines that use remote condensers have several components that are not used in self

contained machines. A

mixing valve

controls the head pressure when the ambient

temperature at the condenser drops below 70°F (21°C). When the bin fills with ice or is

turned off at the selector switch, the machine will pump all the refrigerant into the receiver

before shutting off.

Remote Condenser

For proper operation, the remote condenser must be installed properly.

Improper installation will void the warranty. See remote guidelines on

page A10. The location of the remote condenser should be such that the

ambient air temperature does not exceed 120°F (48.9°C). If ambient

temperature exceeds 120°F (48.9°C) ice production will decrease until the

ambient temperature decreases.

If the airflow is restricted or the condenser is dirty, the head pressure will

be excessively high, slow production will result and the compressor may

overheat and eventually become damaged. The condenser coil and fan

blades must be kept clean. The condenser can be cleaned with

compressed air or by using a brush. If a brush is used, brush in the direction of the fins

taking care not to bend the fins. If the condenser fins are bent, this will restrict the airflow

through the condenser and the fins will need to be straightened with a fin comb. Problems

related to a dirty condenser or poor airflow will not be covered under warranty.

Note

: The

condenser fan motor runs continually, it will shut off when the icemaker shuts off.

Air Flow

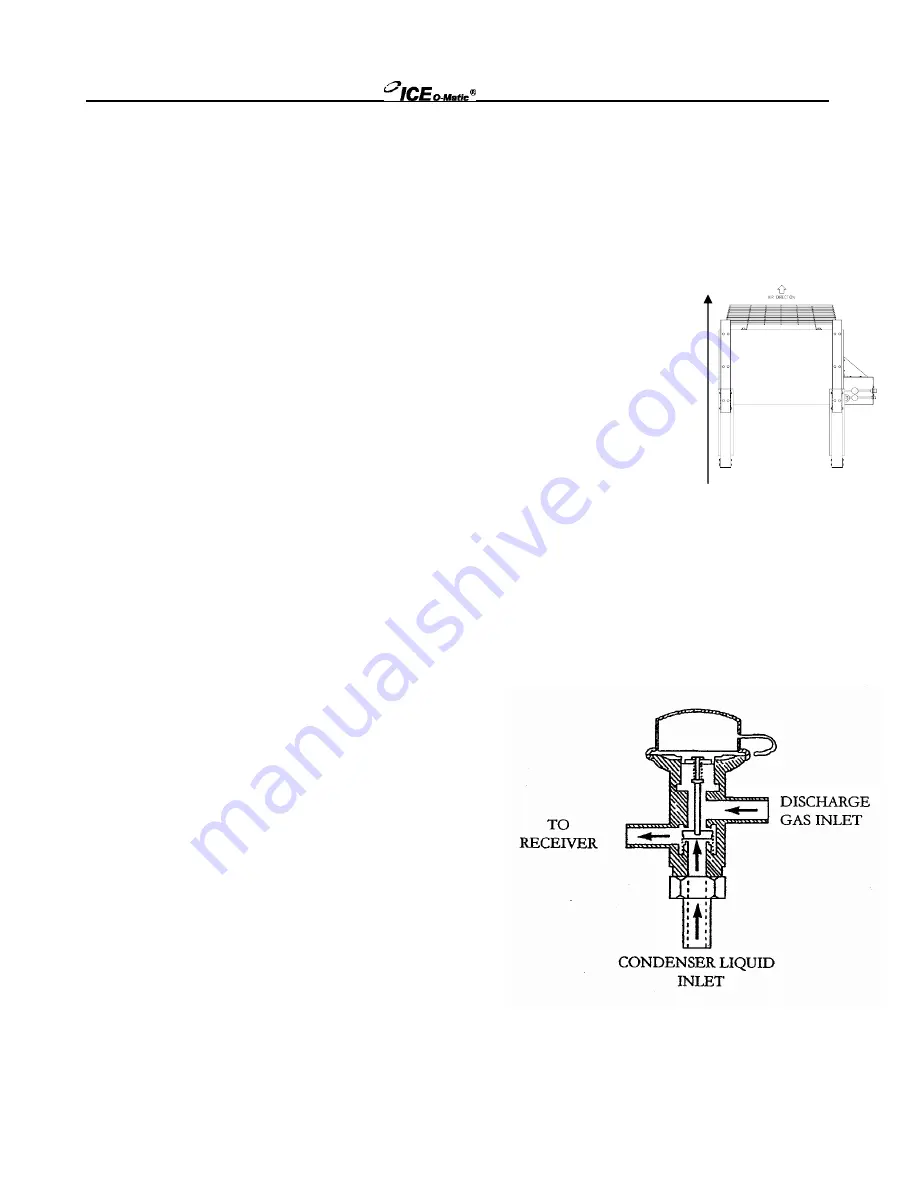

Mixing Valve (L.A.C., Headmaster)

When the temperature at the condenser is above

70°F (21°C), the refrigerant flow from the

compressor is directed by the mixing valve

through the condenser and into the receiver.

When the temperature at the condenser drops

below 70°F (21°C), the pressure in the bellows of

the mixing valve becomes greater than the

pressure of the liquid refrigerant coming from the

condenser. This change allows the valve to

partially restrict the flow of refrigerant leaving the

condenser and allows discharge gas to by-pass

the condenser and flow directly into the receiver,

mixing with the liquid refrigerant from the

condenser. The amount of discharge gas that

bypasses the condenser increases as the ambient

temperature decreases. This action of the mixing

valve allows the discharge pressure to be maintained at approximately 240 psi (16.5 bar)

during low ambient conditions. If the refrigerant system is undercharged and the ambient

temperature is below 70°F (21°C), the mixing valve will not work properly. The mixing valve

will allow too much refrigerant to bypass the condenser.

Summary of Contents for EF Series

Page 2: ......

Page 6: ......

Page 9: ...Flake Ice Machines General Information Page A7 EF Series ...

Page 10: ...Flake Ice Machines General Information Page A8 EMF Series ...

Page 11: ...Flake Ice Machines General Information Page A9 EMF Series 48 Inch Wide ...

Page 20: ...Flake Ice Machines Troubleshooting Trees Page C2 Machine Runs Does Not Make Ice ...

Page 21: ...Flake Ice Machines Troubleshooting Trees Page C3 Machine Runs Does Not Make Ice ...

Page 22: ...Flake Ice Machines Troubleshooting Trees Page C4 Machine Does Not Run ...

Page 23: ...Flake Ice Machines Troubleshooting Trees Page C5 Slow Production ...

Page 24: ...Flake Ice Machines Troubleshooting Trees Page C6 Low Production ...

Page 25: ...Flake Ice Machines Troubleshooting Trees Page C7 High Suction Pressure ...

Page 26: ...Flake Ice Machines Troubleshooting Trees Page C8 Machine Freezes Up Auger Seizes ...

Page 27: ...Flake Ice Machines Troubleshooting Trees Page C9 Auger Motor Amp Draw Fluctuates ...

Page 28: ...Flake Ice Machines Troubleshooting Trees Page C10 Water Leaking From Bottom of Evaporator ...

Page 29: ...Flake Ice Machines Troubleshooting Trees Page C11 Machine Produces Wet Ice ...

Page 31: ...Flake Ice Machines Troubleshooting Trees Page C13 Noise Coming from Evaporator ...

Page 41: ...Flake Ice Machines Drive System Page E8 Exploded View of the Evaporator ...

Page 43: ......

Page 46: ......

Page 61: ...Flake Ice Machines Electrical System Page G6 9071694 01 EF250 255 405 EF450A W ...

Page 62: ...Flake Ice Machines Electrical System Page G7 9071963 01 EF800A W ...

Page 63: ...Flake Ice Machines Electrical System Page G8 EMF450 405A W 9071958 01 ...

Page 64: ...Flake Ice Machines Electrical System G9 Page 9071954 01 EMF800A W ...

Page 65: ...Flake Ice Machines Electrical System Page G10 9071956 01 EMF705 1005 1006A W ...

Page 66: ...Flake Ice Machines Electrical System Page G11 9071962 01 EMF1106R ...

Page 67: ...Flake Ice Machines Electrical System Page G12 9071955 01 EMF2306A W ...

Page 68: ...Flake Ice Machines Electrical System Page G13 9071960 01 EMF2306R ...

Page 69: ...Flake Ice Machines Electrical System Page G14 9071959 01 EMF2305L ...

Page 70: ......

Page 71: ......

Page 72: ......