Dieses Gerät ist berechtigt, in Übereinstimmung mit dem Deutschen EMVG das EG-Konformitätszeichen -

CE - zu führen.

Verantwortlich für die Einhaltung der EMV-Vorschriften ist der Hersteller:

International Business Machines Corp.

New Orchard Road

Armonk, New York 10504

Tel: 914-499-1900

Der verantwortliche Ansprechpartner des Herstellers in der EU ist:

IBM Deutschland GmbH

Technical Relations Europe, Abteilung M456

IBM-Allee 1, 71139 Ehningen, Germany

Tel: +49 800 225 5426

e-mail: [email protected]

Generelle Informationen:

Das Gerät erfüllt die Schutzanforderungen nach EN 55024 und EN 55032 Klasse A.

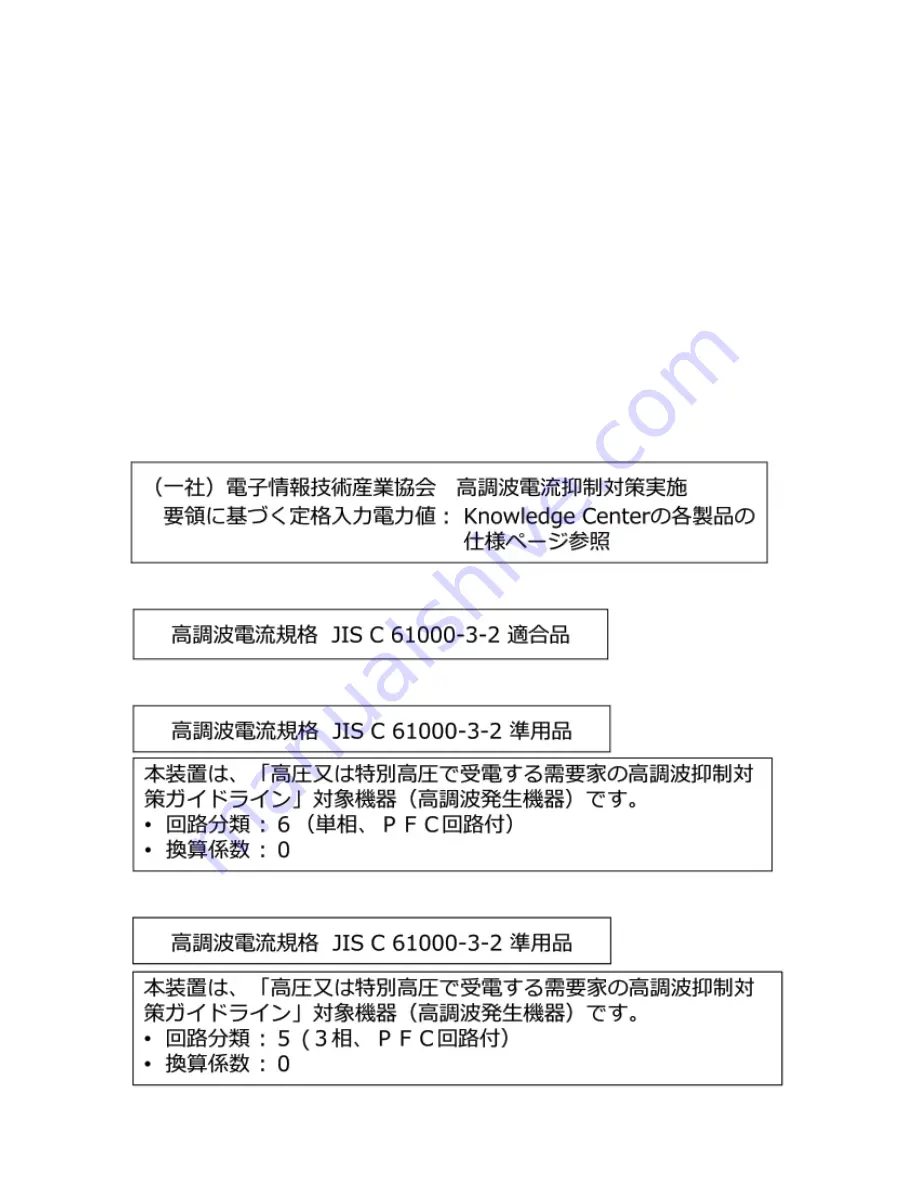

Japan Electronics and Information Technology Industries Association (JEITA) Notice

This statement applies to products less than or equal to 20 A per phase.

This statement applies to products greater than 20 A, single phase.

This statement applies to products greater than 20 A per phase, three-phase.

114 Notices

Summary of Contents for Storwize V5100 MTM 2078-424

Page 143: ......