13

Maintenance

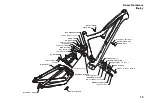

Working on your Ripley

Should you find it necessary to

replace any of the bearings on the Ri-

pley eccentric linkages, you will need

to remove the swingarm. For that,

you will need the following tools:

• 12mm open end wrench

• 15mm socket wrench

• 2 x 6mm Allen wrench

• 1 x 5mm Allen wrench

• 2 x 4mm Allen wrenches

Bearing Replacement:

Please refer to the section on Ripley

Swingarm Removal on pages 44–45.

Ibis will be offering a bearing remov-

al tool in addition to a bearing press

in mid 2013. Complete instructions

will be included in the next version of

this guide.

Ripley Bearing Specs:

Eccentric Core Inner Bearings:

• 6806-2RS (30 x 42 x 7)

These are the same size as BB30

bearings.

Lower outer bearings

• 608-RS 8x22x7

These mount in the swingarm and

can be found in skate shops.

Upper outerbearing

• 698-RS 8x19x6

These mount in the swingarm and

can be found in skate shops.

The Ripley uses the following shock and

shock hardware:

Upper Hardware:

• 21.8mm wide with an 8mm bore

Lower Hardware:

• Bushing removed, use provided clevis

bolt

Ripley Shock:

7.25” (184mm) eye to eye

1.75” (44mm) shaft travel

All Mojos use the same shock

mounting hardware.

Upper Hardware:

• 21.8mm wide with an 8mm bore

Lower Hardware:

• 40mm wide with an 8mm bore