2

SL 45-260

PROPANE CONVERSION PARTS KIT# P-170B

120-166 R2

Refer to the details in the boiler’s current Installation and Operation Manual,

section 3.3 - “COMMISSIONING”, 3.4 “FUEL CONVERSION”

The Low Fire (Zero-offset) valve adjustment cap on the gas valve has been factory

set.

This screw (4mm Hex) must not be tampered with. The Zero-offset

screw is not to be adjusted in the field.

Consult factory for written instructions if

considering field adjustment of the Low Fire (zero offset) adjustment.

The High Fire (Gas:Air) ratio adjustment screw (2.5mm Hex) will have to be

adjusted to attain optimum combustion results whenever fuel conversion is

undertaken, however,

no mixture adjustment shall be performed unless

done by a qualified technician using properly functioning and calibrated

combustion analyzing equipment.

The following procedure must be carried out

by a qualified technician:

MODEL

HIGH FIRE

LOW FIRE

CO MAX

PPM

RANGE

TARGET

RANGE

TARGET

SL 35-199

(Natural Gas) CO

2

9.1 – 9.7

9.5

8.4 – 9.0

8.7

150

SL 35-199

(Propane) CO

2

10.5 – 11.1

10.8

9.4 – 10.2

9.8

180

SL 45-260

(Natural Gas) CO

2

9.1 – 9.7

9.5

8.4 – 9.0

8.7

120

SL 45-260

(Propane) CO

2

10.5 – 11.1

10.8

9.4 – 10.2

9.8

150

Table 2: Combustion Test Target Range – CO

2

Fuel Conversion Instructions

The following procedure must be carried out by a qualified technician.

1. Ensure you are installing the correct fuel conversion kit for your boiler.

Compare the boiler model number with the Kit# found in table #1. Ensure you

have the correct Orifice by checking the Orifice size with the Chart on page 3.

2. Ensure the fuel conversion instructions supplied with the fuel conversion kit are

read, understood and followed carefully.

3. The gas supply shall be shut off prior to disconnecting the electrical power, and

before proceeding with the conversion. Ensure that the gas supply is turned off

at the gas shut off valve.

4. Using a #25 Torx wrench, undo the 3 venturi mounting screws.

5. Lift the gas valve up and away from the venturi.

6. Insert the orifice in to the O-ring and re-seat the gas valve on the venturi.

7. Re-install the 3 venturi mounting screws and tighten.

8. Restore gas supply by opening the gas control valve, and using an approved

leak detection solution, soap test all joints.

9. Carefully follow the procedures on page 3, Combustion Testing and Adjustment

10. Place the conversion labels associated with the new fuel onto the boiler at the

positions indicated page 4 of this Instruction Document.

CAUTION

The gas supply shall be shut off

prior to disconnecting the electrical

power, before proceeding with the

conversion.

DANGER

A combustion test must be done

by a qualified, trained and licensed

gas fitter in order to complete any

fuel conversion.

Making adjustments to the IBC gas

valve without a properly calibrated

gas combustion analyzer and by

persons who are not trained and

experienced in its use is forbidden.

Failure to use an analyzer can

result in an immediate hazard.

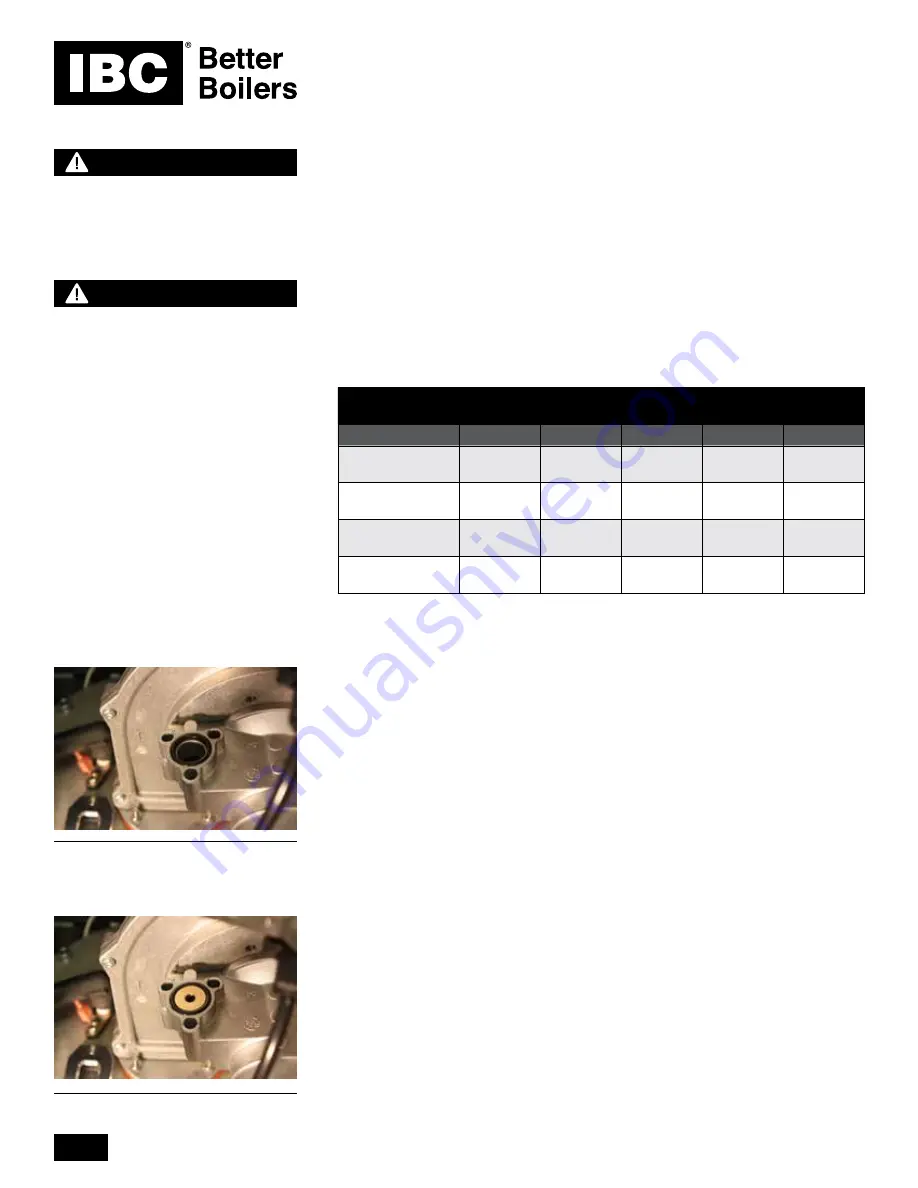

Venturi without an orifice in an SL 45-

260 Natural Gas boiler. This Natural

Gas model does not use an orifice.

Orifice inserted for an SL 45-260 boiler

using Propane.