NOTE:

Check your Parts Manual to make sure this

software applies to the Lift Truck you are servicing.

The Truck Configuration screen contains several

drop-down list boxes for configuring the hydraulic

controller to the truck to which it is connected. See

Figure 7.

Users can select the desired unit of measure (impe-

rial or metric) from the drop-down list box on the

right.

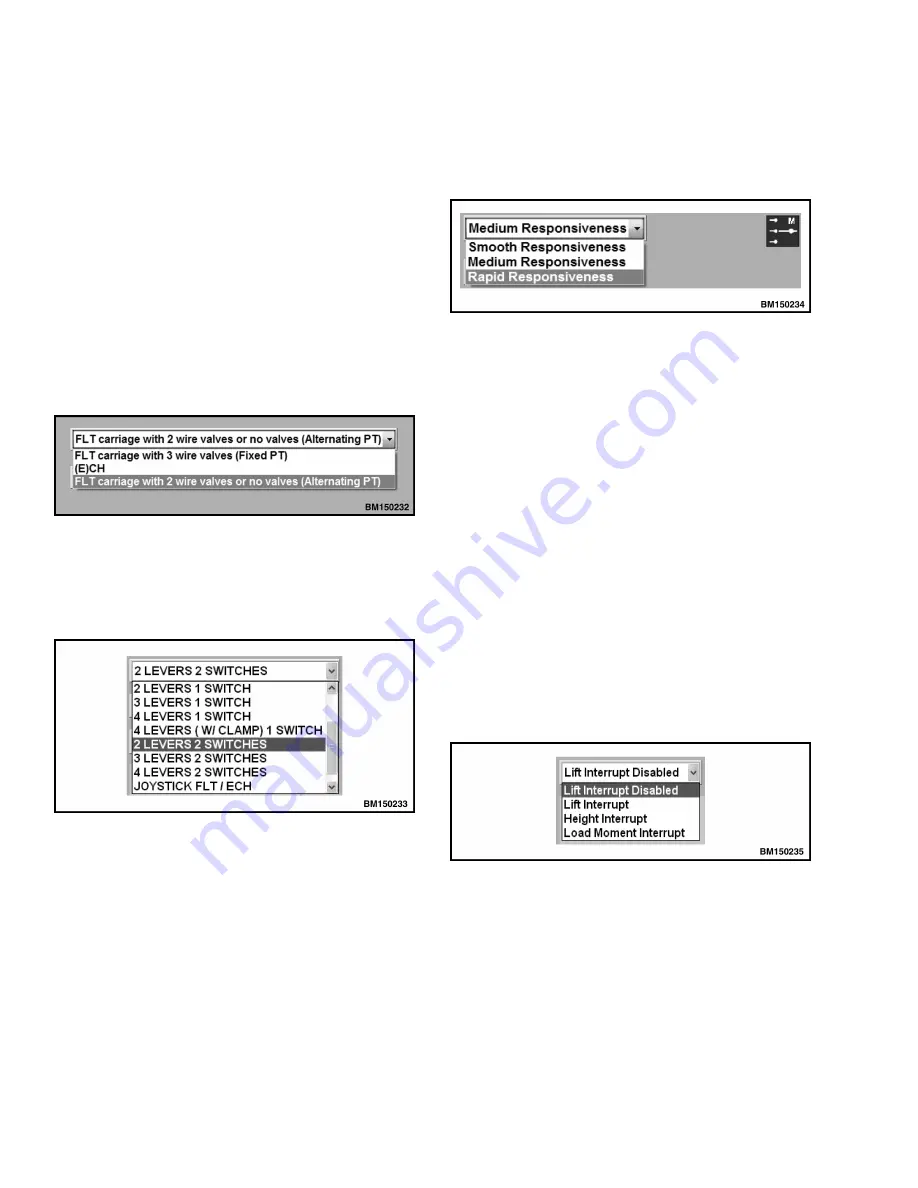

The first drop-down list box on the left lists the

types of front-end valve. The carriage type and ac-

companying valves associated with the truck will

determine which choice to select. See Figure 8.

Figure 8. Front-End Valve Drop-Down List Box

The next drop-down list box lists the possible hy-

draulic input devices. See Figure 9.

Figure 9. Hydraulic Input Devices Drop-Down List

Box

The next drop-down list box is for selecting the de-

gree of responsiveness in the hydraulic system. In

addition, a hyper link displays to the right of the

drop-down list box representing the active mode.

When clicked on, this link will take the user to the

appropriate mode definition subscreen. See Fig-

ure 10.

Figure 10. Hydraulic Responsiveness Drop-Down

List Box

NOTE:

The Lift/Height Interrupt drop-down list

box is an optional feature that can be enabled/disa-

bled if the truck has the necessary hardware. The

hardware may be obtained via SPED.

The Interrupt function limits the movement of the

mast depending on the appropriate input. For the

lift and height interrupt, an input pin on the con-

troller is defined and when this input is active the

movement of the mast is interrupted. See Fig-

ure 11. For Load Moment Interrupt, the pressure

signal from the pressure transducer placed in the

lift section is used. This interrupt is active at a cer-

tain pressure signal and inactive below a certain

pressure signal. Both Lift/Height Interrupt and

Load Moment Interrupt values are adjustable at

the service/technician or engineering level of the

Hydraulic User Interface program.

Figure 11. Lift/Height Interrupt Drop-Down List

Box

General Functions of the Interface

2200 SRM 1481

16