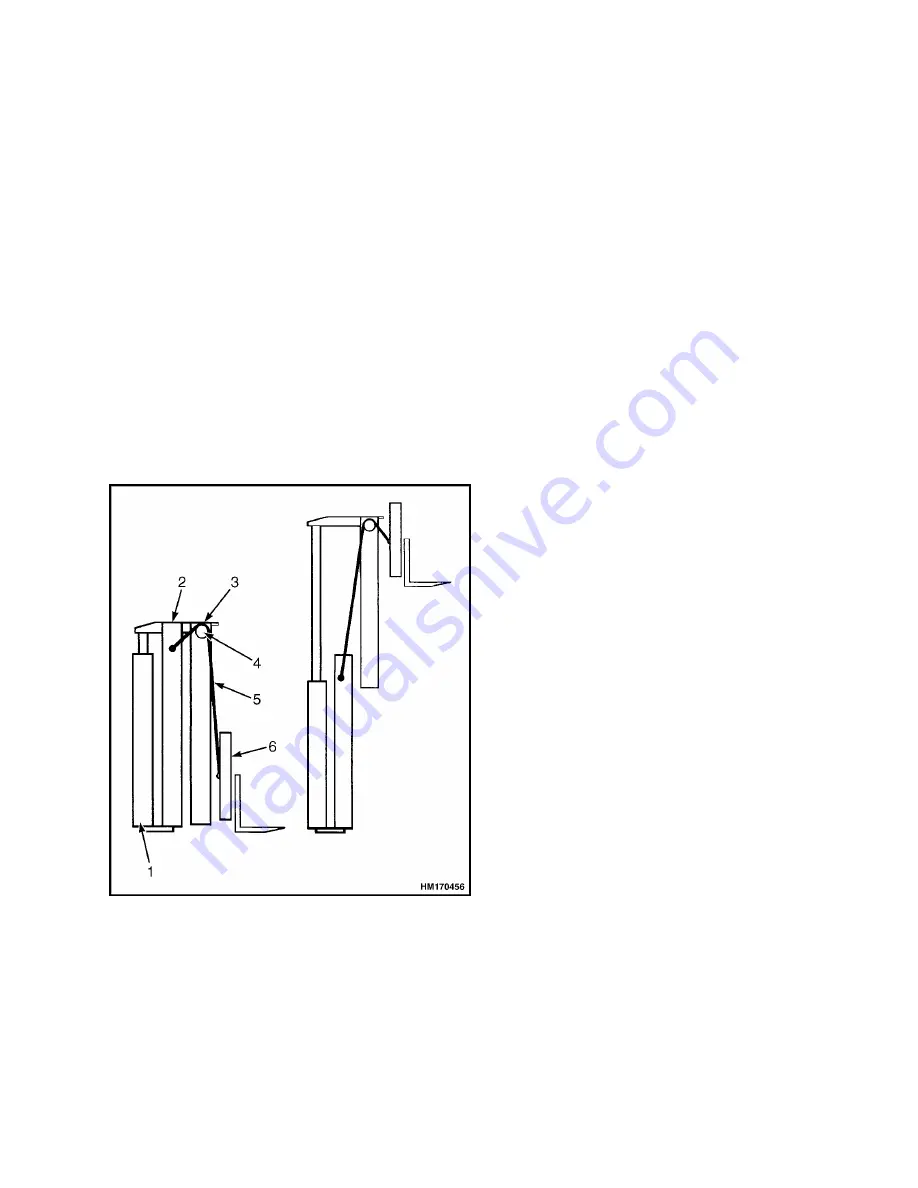

LIFTING

The lift cylinders are supported at the base of the

outer mast. When the cylinders extend, they push

the inner mast upwards. The chains are attached to

the outer mast and the carriage, and they run over

the chain sheaves at the top of the inner mast.

When the inner mast moves upwards, the chains

pull the carriage upwards to twice the distance that

the lift cylinders have extended. See Figure 4.

Operation

The lift cylinders extend when the hydraulic

pressure applied is sufficient to lift the combined

weight of the load, forks, carriage and inner mast.

The raised position of the mast is maintained by

hydraulically closing off the piston side of the lift

cylinders. Lowering is achieved by releasing

hydraulic pressure, which is induced by the weight

resting on the rod of the lift cylinders.

1. LIFT CYLINDERS

2. OUTER MAST

3. INNER MAST

4. CHAIN SHEAVE

5. LIFT CHAIN

6. CARRIAGE

Figure 4. Operation of a Two-Stage Mast

Lifting speed and lowering speed are controlled by

the moved position of the lift spool in the main

control valve. Maximum lifting speed is determined

by maximum pump supply. Maximum lowering

speed is determined by the lowering control valve at

the bottom of each lift cylinder.

The lowering control valve is a pressure

compensated valve. It allows an increasing flow

with increasing pressure until a preset maximum

flow is reached. The result is that similar lowering

speeds are obtained for loaded and unloaded

conditions. The primary function of the lowering

control valve is to limit the lowering speed in case of

a malfunction of the supply/return connection.

The different lift height capacities are determined

by the dimensions of the various mast assemblies.

The lowest position of the forks is determined by the

adjustment of the chain anchors.

Pilot Operated Check Valves

The lift spool in the main control valve does not seal

completely in the neutral position. To obtain zero

leakage, a pilot operated check valve is mounted in

the main control valve between lift spool and lift

cylinder. See Figure 5.

When raising the mast, oil supply will pass through

a check valve in the pilot operated check valve. To

lower the mast, the pilot operated check valve must

be moved into the open position.

The position of the pilot operated check valve, is

determined by oil pressure at the cylinder side of

the check valve, and by the combined force of a

spring and the oil pressure at the pilot side of the

check valve. Spring force will keep the check valve

closed when equal pressures exist at the pilot side

and cylinder side of the check valve.

The pilot operated check valve opens when pressure

is removed from the pilot side of the check valve,

which connects with the selector valve. The selector

valve opens when the lift spool has moved into the

lowering position, which allows pilot pressure from

the spool to reach the selector valve. After the

selector valve has opened and drained pilot pressure

from the pilot operated check valve, the oil from the

lift cylinders will drain through the check valve and

lift spool to the tank.

4000 SRM 1664

Description And Operation

3