OPERATION

4-8

HySpeed HT2000LHF

Instruction Manual

6

Turn Gases On

4. Set S2 toggle switch on the gas console to Run

.

5. Set S1 on the gas console to N

2

/Air (for nitrogen or air as plasma gas), or O

2

(for oxygen as plasma gas).

6. Turn the required supply gases On

.

Note: See the

Cut Charts

to set the plasma and shield gas inlet pressures.

Turn Power Supply On and Adjust Voltage & Current

7. Turn the main disconnect switch ON. See

Status Indicators Before Startup

earlier in this section.

8. Turn on the power supply by depressing and holding down the POWER ON (I) button (PB1) on the power

supply. Ensure that the green POWER ON indicator illuminates. Hold PB1 down until all of the status indicators

extinguish.

9. Set the voltage and current from the Digital Remote Voltage and Current Console or from the machine computer

interface. Select the arc current and arc voltage from the

Cut Charts

for the type and thickness of metal to cut.

PLASMA

N

2

/Air

O

2

SHIELD

N

2

/Air

psi

psi

psi

DC

N

2

/Air

O

2

O

2

PLASMA

Cut Flow

PreFlow

PreFlow

Run

10

9

8

7

6

5

4

3

2

1

0

10

9

8

7

6

5

4

3

2

1

0

Test

Preflow

Test

Cutflow

HySpeed

®

HT2000LHF

®

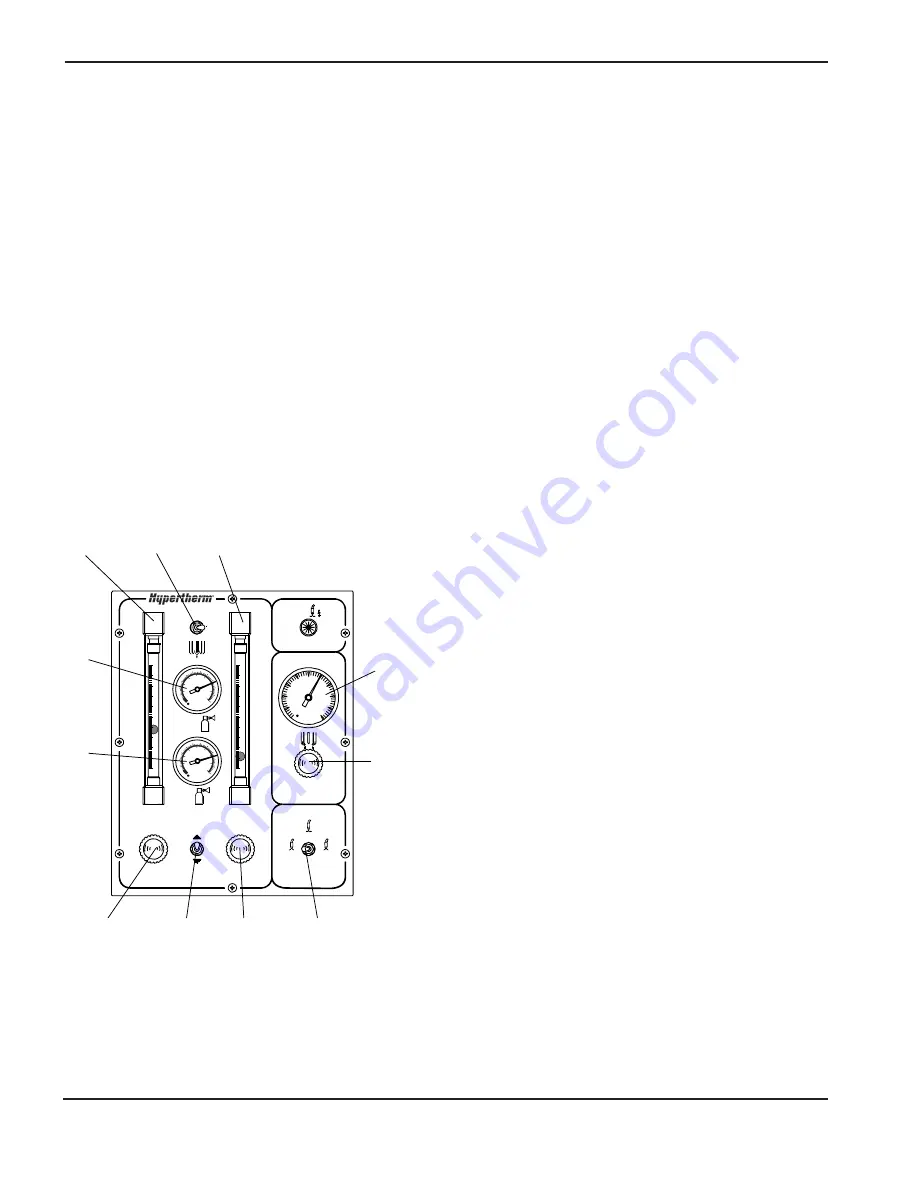

Adjust Preflow Gases

10. Set S2 on the gas console to Test Preflow. Verify the

plasma gas inlet pressure reading on the plasma

pressure gauges (PG1, PG2) on the gas console.

Refer to the

Cut Charts

for the proper pressure

setting.

11. Look at the oxygen (FM2) and/or nitrogen-air (FM1)

flowmeters on the gas console and set the Preflow

plasma gas flow rate % by referring to the

Cut Charts

and turning the oxygen (MV3) and/or nitrogen / air

(MV2) preflow metering valves.

12. Look at the shield gas pressure gauge (PG3) on the

gas console, and set to the

Cut Chart

specifications

by turning the shield gas metering valve (MV4).

Note: If you have changed consumable parts or if the

power supply has been off for more than 1 hour,

purge gas lines by leaving system in Test Preflow

for 1 minute.

FM1

PG1

PG2

PG3

MV4

S1

FM2

MV2

MV1

MV3

S2

Summary of Contents for HT2000LHF

Page 1: ...200 Volt Plasma Arc Cutting System Instruction Manual 803040 Revision 7 HySpeed HT2000LHF ...

Page 5: ......

Page 15: ...TABLE OF CONTENTS viii Hyspeed HT2000LHF Instruction Manual 6 ...

Page 109: ...MAINTENANCE 5 20 HySpeed HT2000LHF Instruction Manual 7 ...

Page 133: ......

Page 134: ...7 5 7 Figure 7 1 HT2000LHF Coolant Flow Diagram ...

Page 135: ......

Page 136: ...7 7 7 ...

Page 137: ......

Page 138: ...7 9 7 ...

Page 139: ......

Page 140: ...7 11 7 ...

Page 141: ......

Page 142: ...7 13 7 ...

Page 143: ......

Page 144: ...7 15 7 ...

Page 145: ......

Page 146: ...7 17 7 ...

Page 147: ......

Page 148: ...7 19 7 ...

Page 149: ......

Page 150: ...7 21 7 ...

Page 151: ......

Page 152: ...7 23 7 ...

Page 153: ......

Page 154: ...7 25 7 ...

Page 155: ......

Page 157: ......

Page 159: ......

Page 174: ...APPENDIX A ARGON HYDROGEN CUTTING AND GOUGING a 14 HySpeed HT2000LHF Instruction Manual 6 ...

Page 176: ...b 2 ...

Page 177: ...b 3 ...

Page 178: ...b 4 ...

Page 179: ...b 5 ...

Page 181: ...b 7 ...

Page 182: ...b 8 ...

Page 183: ...b 9 ...

Page 184: ...b 10 ...

Page 194: ...APPENDIX E AIR FILTERS e 2 Hyspeed HT2000LHF Instruction Manual 6 ...

Page 196: ...APPENDIX F AERATION MANIFOLD FOR CUTTING ALUMINUM f 2 Hyspeed HT2000LHF Instruction Manual 6 ...

Page 198: ...APPENDIX G IEC SYMBOLS g 2 Hyspeed HT2000LHF Instruction Manual 6 ...