ENGINE 3-20

DE-CARBONING

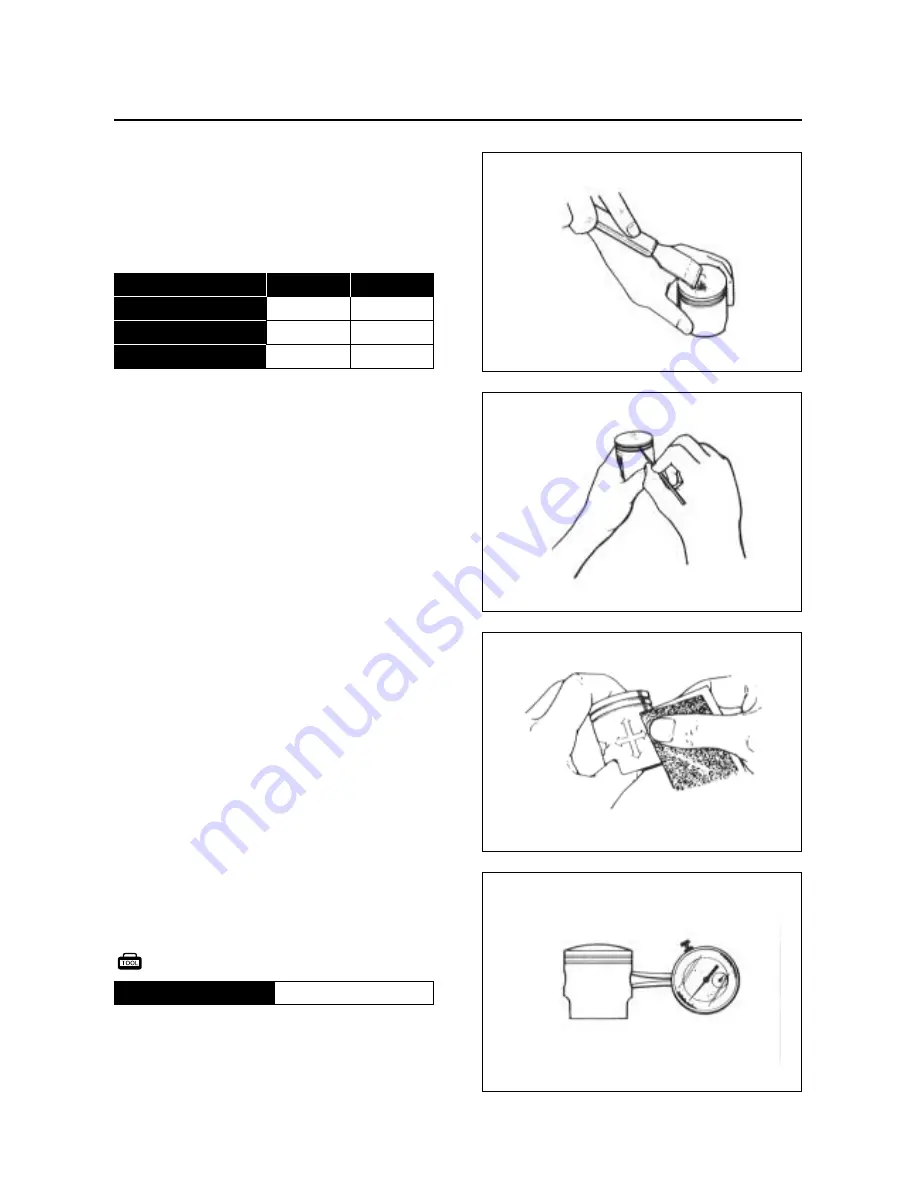

De-carbon the piston and piston ring grooves, as illus-

trated. After cleaning the grooves, fit the rings and rotate

them in their respective grooves to be sure that they

move smoothly.

Carbon in groove is liable to cause the piston ring to get

stuck in the groove, and this condition will lead to

reduced engine power output.

A piston whose sliding surface is badly grooved or

scuffed due to overheating must be replaced. Shallow

grooves or minor scuff can be removed by grinding with

emery paper of about # 400.

PISTON PIN BORE I.D.

Using a caliper gauge, measure the piston pin bore

inside diameter. If reading exceeds the following service

limit, replace it with a new one.

Cylinder bore

Piston diameter

Cylinder to piston clearance

Standard

41.005~41.020 mm

40.935~40.950 mm

0.065~0.075 mm

Serivice limit

41.070 mm

40.885 mm

0.120 mm

As a result of the above measurement, if the piston-to-

cylinder clearance exceeds the following limit, overhaul

the cylinder and use an oversize piston, or replace both

cylinder and piston. The measurement for the bore

diameter should be taken in the intake-to-exhaust port

direction and at 20mm from the cylinder top surface.

Dial calipers : 09900-20605

Service limit 10.030 mm

Piston pin bore I.D.