Page 73

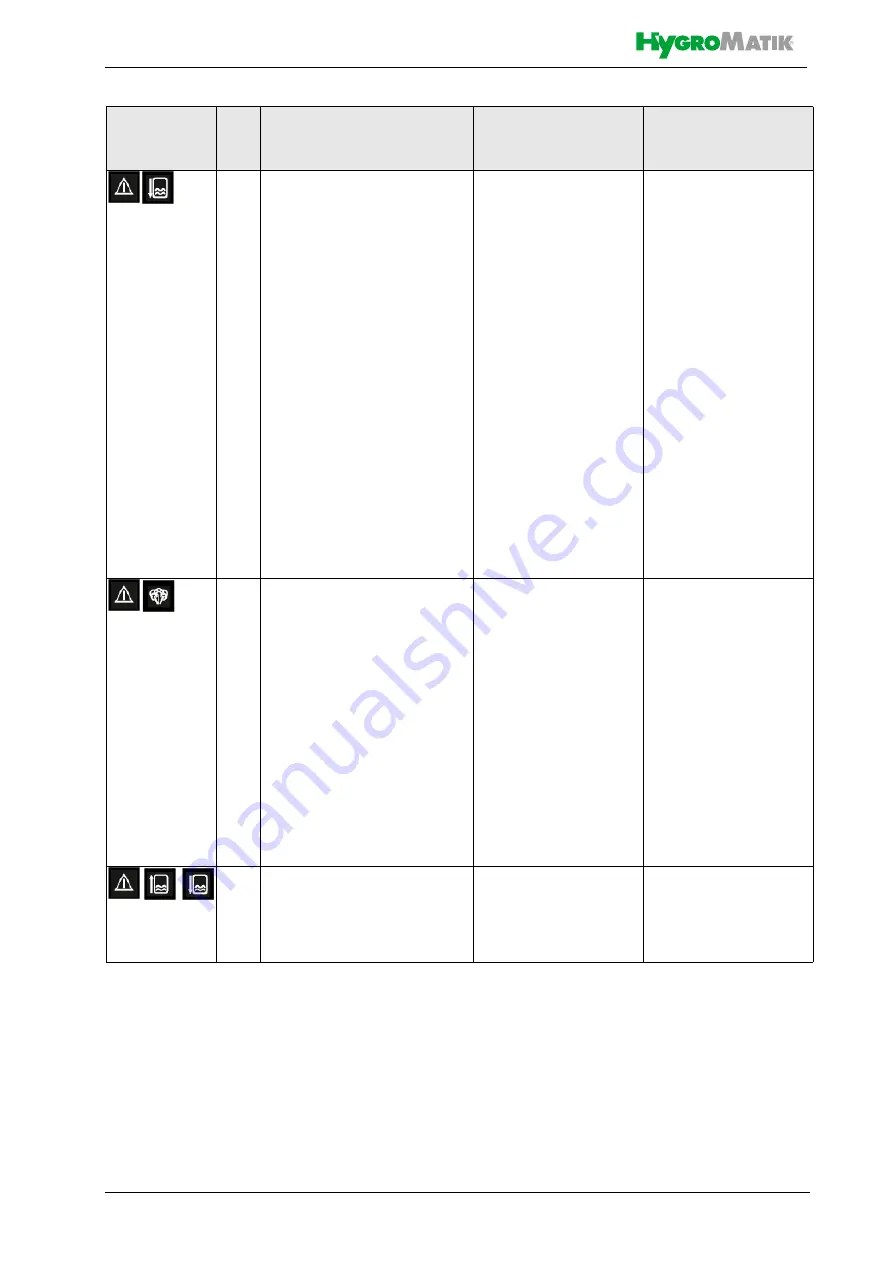

061

062

065

066

067

Blow-down fault

, relates to:

Partial blow-down

Full blow-down

Max level blow-down

Stand-by blow-down

Start_blow-down

Indicated blow-down was not

successful

•

Blow-down pump not

driven

- electrical wiring not

o.k.

- Main PCB relay not

energised

- Check wiring and re-

place, if required

- Measure voltage on

main PCB terminal 10

against N; replace

PCB, if required

•

Blow-down pump de-

fective

•

Replace blow-down

pump

•

Blow-down pump

working but water is

not drained (i.e. cylin-

der drain is blocked)

•

Clean cylinder and

cylinder base carefully

to ensure that no

blocking will occur in

the near future

•

Blow-down pump

blocked by hardeners

•

Check blow-down

pump, drainage sys-

tem and steam cylinder

for hardeners and

clean

120

Thermo switch

One of the thermo switches

has triggered

•

Thermo switch on

steam cylinder cover

has triggered due to

lime coating on heating

element

•

Switch off power sup-

ply. Remove lime coat-

ing. Allow cool-down

of steam cylinder.

Push-back unblocking

pin on thermo switch

with needle-nose pliers

or a screwdriver

•

Capillary tube defec-

tive

•

Replace thermo

switch

•

Thermo switch on

solid state relay has

triggered due to

blocked ventilation

•

Switch off unit. Allow

cool-down of heat sink.

Restart humidifier op-

eration.

121

Water sensor

Water sensor output signal

not plausible

•

Water sensor is

defective

•

Replace water sen-

sor

•

Connecting hoses

blocked

•

Clean hoses

Icons

Code

Error message

Possible cause

Counter measure