INSTALLATION

Hazardous voltage. Can shock, burn or kill.

Do not lift pump by the power cord. See “Cord Lift Warning”

below.

NOTICE:

Install the pump on a hard, level surface (cement,

asphalt, etc.). Never place the pump directly on earth, clay or

gravel surfaces. Install the pump in a sump basin with a

minimum diameter of 18" (46cm).

Piping

Piping must not be smaller than pump discharge.

When installed in a

sewage

system, the pipe must be

capable of handling semi-solids of at least

2"

(51mm) in

diameter.

When installed in an

effluent

system, the pipe must be

capable of handling semi-solids of at least

3/4"

(19mm) in

diameter.

The rate of flow in the discharge pipe must keep any solids

present in suspension in the fluid. To meet minimum flow

requirements (2 feet per second in the discharge line), size

the pipe as follows:

A Pipe Size Of:

Will Handle a Flow Rate Of:

1-1/2" (38mm)

12 GPM

2" (51mm)

21 GPM

2-1/2"(64mm)

30 GPM

3"(76mm)

48 GPM

In a

sewage

system use a

2"

(51mm) check valve in pump

discharge to prevent backflow of liquid into sump basin. The

check valve should be installed 12–18" (317–457mm) above the

pump discharge and be a free flow valve that will easily pass

solids. Be sure check valve installation complies with local codes.

In an effluent system use a

1-1/2"

(28mm) check valve in pump

discharge to prevent backflow of liquid into sump basin.

NOTICE:

For best performance of check valve when handling

solids, do not install it with the discharge more than 45° above

the horizontal. Do not install the check valve in a vertical

position as solids may settle in the valve and prevent it from

opening on startup.

Drill a 3/16" (5mm) hole in the discharge pipe about 1–2"

(25-51mm) above the pump discharge connection (but below

check valve) to prevent airlocking the pump.

Be sure that the wide-angle float switch hangs freely. It should

not be able to come in contact with the sides or bottom of the

sump pit.

Make sure the sump pit is free of any debris that could

obstruct the intake volute or switch.

Use plumbing materials that are approved by local building

codes when connecting pipes between pump and sewer

outlet.

NOTICE:

For critical indoor installations where additional

high water protection is desired, install a “Q-Alert” audible

alarm system in the sump pit. For outdoor installations,

confer with your Hydromatic distributor.

Connect the power cord to a 3-prong grounded AC

receptacle.

Hazardous voltage. Can shock, burn or kill.

DO NOT remove the grounding pin from the power cord.

Avoid using extension cords or 2-prong adapter plugs.

Insert the piggyback plug that comes from the wide-angle

float switch directly into the power receptacle.

Insert the pump power cord directly into the back of the

piggyback plug.

Test the pump installation by filling the sump basin with

enough water to activate the pump and repeat this cycle until

satisfied with pump operation.

Electrical

Hazardous voltage. Can shock, burn, or kill.

When installing, operating, or servicing this pump, follow the

safety instructions listed below.

1.

DO NOT

splice the electrical power cord.

2.

DO NOT

allow the plug on the end of the electrical cord

to be submerged.

3.

DO NOT

use extension cords. They are a fire hazard and

can reduce voltage sufficiently to prevent pumping and/or

damage motor.

4.

DO NOT

handle or service the pump while it is

connected to the power supply.

5.

DO NOT

remove the grounding prong from the plug or

modify the plug. To protect against electrical shock, the

power cord is a three-wire conductor and includes a 3-

prong grounded plug. Plug the pump into a 3-wire,

grounded, grounding-type receptacle. Connect the pump

according to the NEC or CEC and local codes.

For automatic operation, plug the pump into the piggy-back

switch plug. Plug the piggy-back switch plug into the outlet.

For continuous running, plug the pump directly into the outlet

(that is, bypass the piggyback switch plug).

2

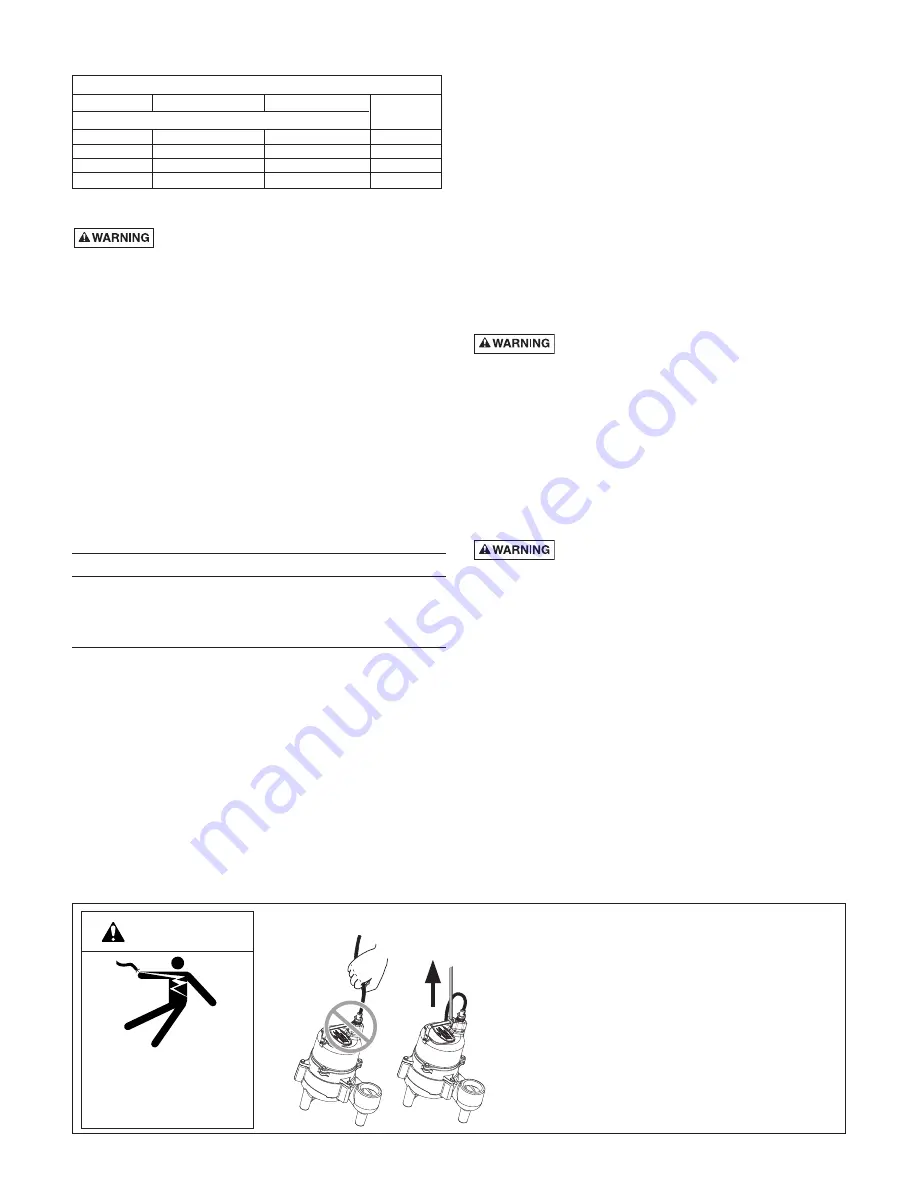

1. Attempting to lift or support pump by power cord

can damage cord and cord connections.

2. Cord may pull apart, exposing bare wires with

possibility of fire or electrical shock.

3. Lifting or supporting pump by power cord will

void warranty.

4. Use lifting ring or handle on top of pump for all

lifting/lowering of pump. Disconnect power to

pump before doing any work on pump or

attempting to remove pump from sump.

Risk of electrical shock.

Can burn or kill.

Do not lift pump by

power cord.

WARNING

CORD LIFT WARNING

PERFORMANCE

GPM AT TOTAL FEET

Model

10

15

CAPACITY GALLONS/MINUTE

SKV40M1

78

40

19

SKV40A1

78

40

19

SKV40M2

78

40

19

SKV40A2

78

40

19

No flow

at height

shown below

Summary of Contents for SKV40

Page 8: ......