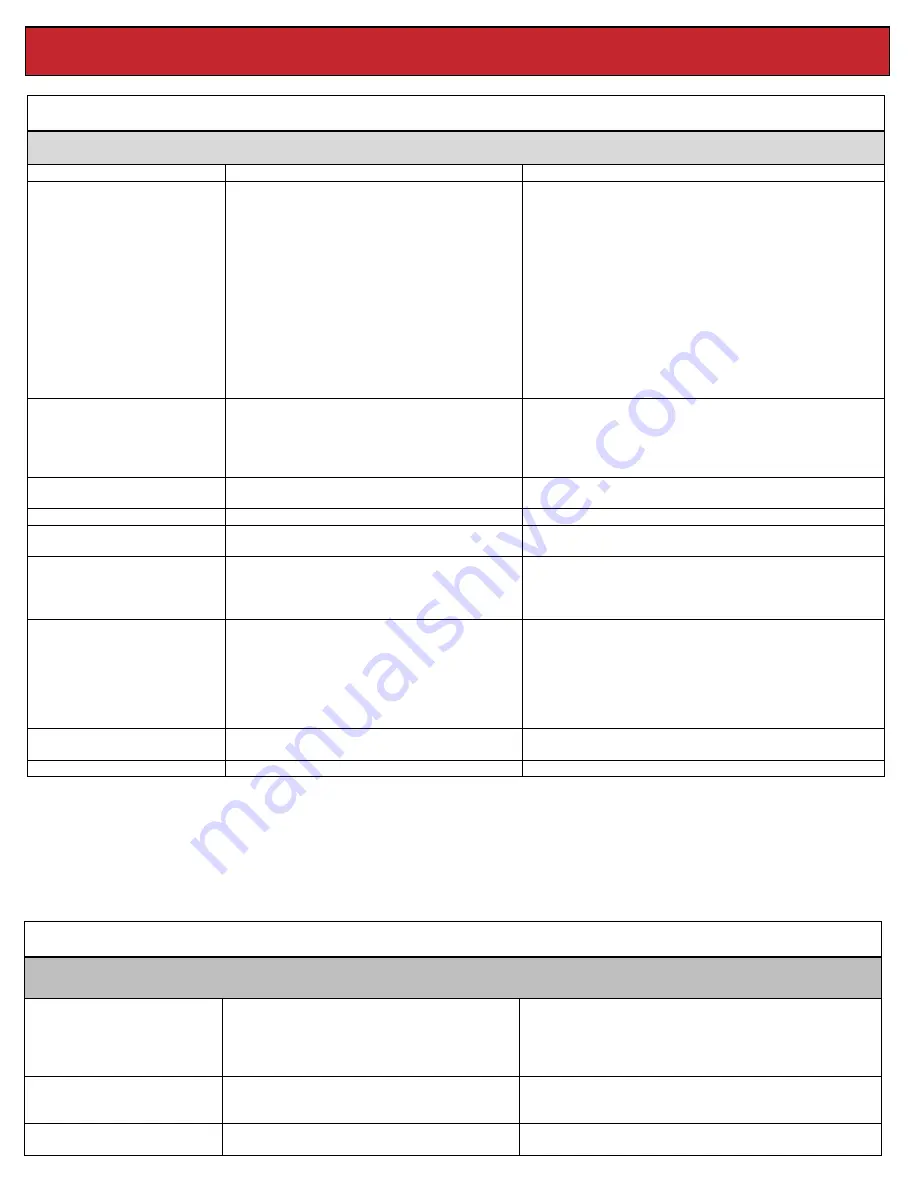

PROBLEM

PROBABLE CAUSE

(The most recurring probable cause is listed first)

REMEDY

(Repairs should only be made by a qualified technician)

Pumping System

Trigger gun leaks or will not shut off

Debris in gun valve assembly.

Clean valve assembly or replace gun.

Pump runs but has low spray pressure Water turned off.

Nozzle is not installed, is plugged, or sized incorrectly

Inlet chemical injection valve is open without the end of the

pickup tube inserted into detergent.

Coil on hot water machines is obstructed.

Priming of pump after run dry.

Dual wand valve is open.

Leaky discharge hose or quick coupler. Water sprays out

around nozzle.

Inlet strainer clogged.

Belt slippage.

Unloader valve worn or improperly adjusted.

Air leak in inlet plumbing.

EZ start valve is leaking.

Turn water on.

Install nozzle, clean or replace with proper size

Close soap valve or submerge detergent pickup tube into solution.

Clean obstruction or scale deposits from coil with coil cleaner.

Crack open fitting on high-pressure outlet of pump.

Close dual wand valve and install high-pressure nozzle.

Replace hose, quick coupler, or o-ring in the quick coupler.

Clean and check more frequently.

Tighten or replace with correct belt

Install pressure gauge on pump head to adjust pressure.

Check valve seat on unloader.

Reseal fittings and inspect inlet hoses for air leaks.

Pump runs but there is erratic,

fluctuating pressure

Inadequate incoming water supply.

Stuck inlet or discharge valves.

Restricted inlet or air entering the inlet plumbing on pump.

Leaking High Pressure seals

Leaking Low Pressure seals

Remove hose to check for internal leaks. Increase water supply flow.

Clean out or replace worn valves.

Check fittings and hose for airtight seal, clean inlet strainer screen.

Replace seals.

Pressure feed the pump & replace seals if water leaks from pump head.

Excessive crankshaft play or loud,

knocking noise in pump

Broken or worn bearing or connecting rod in crankcase

Replace pump or bearing.

Oil leaking from pump

Loose drain plug or damaged seal

Locate point of oil leakage and replace damaged o-ring/seal.

Water is emitted from the chemical

pickup tube

Check-valve malfunctioning.

Repair or replace check-valve.

Inlet injection will not siphon chemical Check valve in strainer clogged.

Chemical valve not open or clogged.

Strainer not submerged in solution.

Detergent hose cut or kinked.

Clean or replace valve. Rinse after each use.

Open chemical valve or clean.

Submerge strainer and replenish chemical.

Inspect hose, replace as necessary.

Downstream injector will not siphon

chemical

Brass knob on injector is closed.

Unit not in low-pressure mode.

Soap solution is too thick.

Detergent hose cut or kinked.

Strainer plugged or not submerged.

Internal injector parts corroded or stuck.

Outlet water temperature too high.

Open by turning counter clockwise.

Open dual wand or install low-pressure tip.

Dilute or use different solution.

Inspect hose, replace as required.

Check screen on strainer pickup tube.

Disassemble, clean or replace.

Use with cold water (150° Maximum)

Pressure relief relieving water

Un-loader failure/Coil overheating/Excessive pressure.

Turn machine off, wait a few minutes and restart. If problem continues,

take in for repair.

Burst disc relieving water

Excessive over-pressurizing and system spikes.

Take in for system check.

PROBLEM

PROBABLE CAUSE

(The most recurring probable cause is listed first)

REMEDY

(Repairs should only be made by a qualified technician)

Heating / Burner System

– Diesel Fired

(Additional Diesel Fired burner troubleshooting flow chart on next few pages)

Burner smokes

Elevation or altitude

Soot on coil exterior

Exhaust restricted

Air intake restriction

Improper voltage at burner motor

Adjust air band and fuel pressure to compensate

Increase air or decrease fuel. Coil may need cleaning

Remove restriction if obvious. Check for sooted coil

Remove restriction if obvious. Adjust air bands. Check fan

Check generator output if equipped. Check battery or charging system.

Excess carbon monoxide

Too much air

Improper or restricted fuel nozzle

Fuel gun assembly out of adjustment

Adjust air bands

Replace fuel nozzle

Adjust gun assembly location

Burner “Puffs” black smoke

Too much fuel pressure

Not enough air flow

Adjust fuel pressure at fuel pump

Adjust air bands

TROUBLESHOOTING GUIDE

15