8

Vacuum Connections

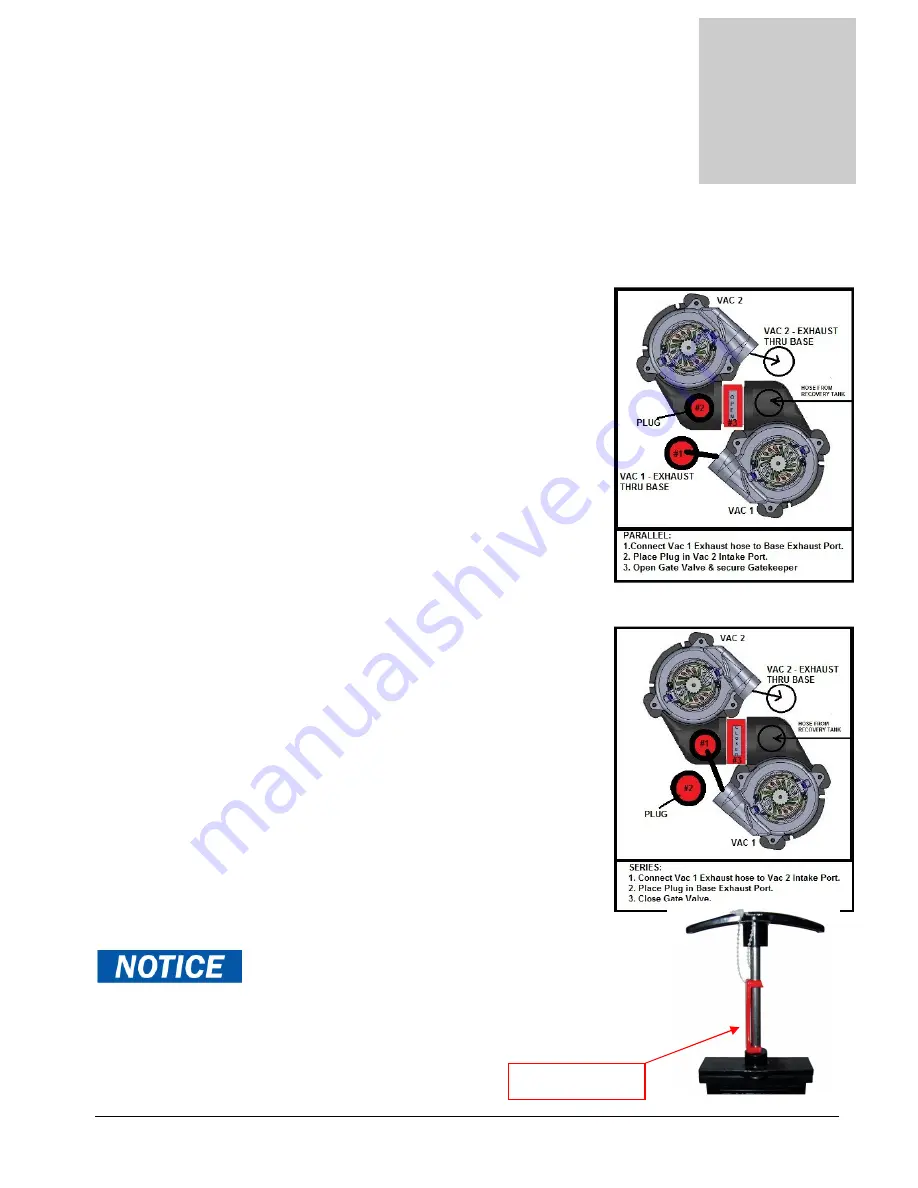

The MX3-1200JP has a unique vacuum system which allows you to

connect your vacuums in either parallel or in series. Vacuum

connections can be changed quickly, with only a screw driver.

While there is debate on which vacuum alignment provides the best

extraction, this much is true:

•

Two vacuums in series: The vacuum lift is increased by 1.6

times the rating of a single vacuum, while the air flow stays the

same as a single vacuum.

•

Two vacuums in parallel: The vacuum air flow is increased by

2.0 times the rating of a single vacuum, while the lift says the

same.

Air flow is usually measured in cubic feet per minute, indicated as

CFM.

Lift is usually measured in inches of water column, indicated as “H2O or “WC.

To connect vacuums in parallel:

1.

Connect the discharge / exhaust hose from vacuum #1 to the

exhaust pipe on machine base.

2.

Place the rubber stopper into the vacuum inlet port of vacuum

manifold number two.

3.

Open vacuum gate valve and attach the Gatekeeper to prevent

accidental valve closure.

When connected in parallel, both vacuums must be running during

cleaning. Vacuums cannot be operated individually.

To connect vacuums in series:

1.

Connect the discharge / exhaust hose from vacuum #1 to the

vacuum inlet port of vacuum manifold number two.

2.

Place rubber stopper into the exhaust pipe on machine base.

3.

Remove Gatekeeper and close vacuum gate valve.

When connected in series vacuums can be operated individually if desired

during cleaning.

Always secure the Gate Valve Open with

the Gatekeeper when connecting the vacuums in Parallel.

Closing the Vacuum Gate Valve with the hoses connected

in the Parallel configuration may

cause damage to Vacuum

#2.

Section

2

GATEKEEPER

Summary of Contents for Nautilus MX3-1200JP

Page 1: ...1 LMANN19 Revised 01 29 2015 Nautilus MX3 1200JP Operating Manual ...

Page 39: ...39 NM5740 AUTO FILL FLOAT VALVE ASSEMBLY ...

Page 41: ...41 Pump Out Pump AP37 PARTS ASSEMBLY ...

Page 42: ...42 1 2 3 5 4 4 6 7 8 9 10 8 9 3 8 9 8 9 23 100 104 12 11 2 39 ...

Page 49: ...49 2 39 1 72 73 73 67 9 30 31 82 83 2 83 82 84 INSIDE SOLUTION TANK BOTTOM VIEW SOLUTION TANK ...

Page 51: ...51 PUMP OUT CONNECTIONS 96 88 112 105 93 99 96 91 95 97 9 111 113 117 119 ...

Page 52: ...52 FLOW 81 92 91 99 96 9 97 105 13 14A 14 95 PUMP OUT PARTS 1 39 9 97 119 ...