Installation of Ducting

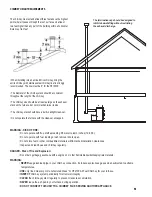

• Proper ducting of the Cold Air Return and Warm Distribution Air is critical to ensure comfort throughout your home.

• Consult a local HVAC contractor for assistance with the design and installation of effective ducting.

• The furnace may be installed as a Dedicated System with separate cold/warm air ducting or an In-line System sharing the ducting of

an existing central furnace. Careful consideration is required for both installations.

• All duct connections should be properly supported, fastened, and sealed to maximize air flow.

• The installation of the furnace within the basement may increase the negative pressure in the basement, especially if there are other

appliances (i.e. dryers, central vac systems) operating in the basement. In these cases, it may be necessary to provide fresh air to the

basement by installing a Fresh Air Kit (WAF-FAK10) to ensure proper performance. Please contact your dealer or call 1-800-875-4788.

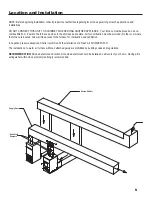

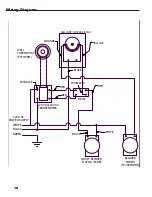

Warm Distribution Air Ducting: Ducting off the Top of the Furnace with Two (2) 8” Collars

• All ducting materials must be approved and listed for 250°F.

• All ductwork should be designed to allow a maximum external static pressure of .20 water column inches.

• Do not install a damper which may reduce the airflow of the distribution air.

• Never alter the top of the furnace by enlarging the 8” duct connection collars. If installing a plenum to the top of the furnace, the

existing openings must remain.

• Never connect the warm air of the wood furnace with the return air of an In-line furnace. The high heat output of the furnace may

overheat the components of the central furnace.

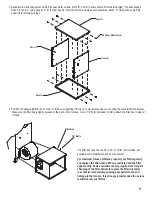

Cold Air Return Ducting: Ducting to Filter Box on Rear of Furnace

• This 2020 EPA-Certified Warm Air Furnace is engineered to perform as a whole home heating solution with the Cold Air Return

connected directly to the heated living area. This can be accomplished by connecting directly to the existing return air ducting or by

installing a properly sized, unrestricted, independent return air system. Failure to do so will impact the comfort level, performance and

efficiency of the overall system.

• The Cold Air Return must be a minimum of 10% larger than the size of the warm air distribution outlets. The minimum size of the

return air must be 110 sq. inches. Failure to provide adequate return air will result in poor performance and overheating of the furnace.

• Connections of ductwork to the rear of the filter box should allow a minimum space of 6” clearance from the filter. Be sure to maintain

required clearances and at no time should the ducting be closer than 6” to an adjacent foundation wall.

• Minimize the use of elbows to maximize airflow and reduce resistance.

•

IMPORTANT:

When direct connecting the return air to the central furnace return air it is necessary to install a back-draft damper on

the warm air side of the central furnace to eliminate pulling the warm distribution air from the wood furnace through the central furnace

and back into the Cold Air Return ducting of the wood furnace.

• Passive Cold Air Return ducting is not recommended but may be accomplished by installing open floor grates, louvers in basement

doors, and registers in existing return air ducting. It is critical to provide adequate return air as described above.

Canadian Requirements for Supplemental/Add-On Furnaces

•DO NOT USE DUCT ELBOWS HAVING AN INSIDE RADIUS OF LESS THAN 6 INCHES (150mm) ON OIL, ELECTRIC, OR GAS

FURNACES.

• DO NOT CONNECT TO A DOWN-FLOW FURNACE.

• DO NOT CONNECT DUCTWORK SO THAT A REVERSE FLOW IS POSSIBLE.

• OPERATE THE GAS/OIL/ELECTRIC/ FURNACE PERIODICALLY TO ENSURE THAT IT WILL OPERATE SATISFACTORILY

WHEN NEEDED.

• CERTIFIED FOR INSTALLATION WITH APPROPRIATE DUCTWORK CONFIGURATIONS ONLY.

• DO NOT RELOCATE OR BYPASS ANY OF THE SAFETY CONTROLS IN THE ORIGINAL GAS/OIL/ELECTRIC FURNACE

INSTALLATION.

• DO NOT CONNECT TO ANY GAS FURNACE THAT HAS NOT BEEN CERTIFIED INITIALLY AS COMPLYING WITH

CAN/CGA-2.3.

• THE OPERATION OF THE GAS FURNACE MUST BE VERIFIED FOR ACCEPTABLE OPERATION BEFORE AND AFTER

INSTALLATION OF THE ADD-ON APPLIANCE BY A GAS FITTER WHO IS RECOGNIZED BY THE

REGULATORY AUTHORITY.

• DO NOT CONNECT TO ANY GAS FURNACE THAT IS NOT EQUIPPED WITH AN AIR-CIRCULATION BLOWER, OR TO A

CHIMNEY OR VENT SERVICING A GAS FURNACE OR GAS APPLIANCE.

10