19

Cover the whole torch cable (from torch holder to output terminal ) of the

cutter with shielding layer, the shielding layer should be metal hose or shielding

net pipe made of aluminum or copper, metal materials which is magnetic

conducted cannot be used, the shielding layer don't need to connect with

ground;

All the control lines which connected with plasma power source should be

shielding wire, the shielding layer should be connected ground well;

The control system of CNC cutting machine should be away from the cutting

table, torch cables and cutting torch head, especially the cutting torch heard.

When striking arc, the high frequency spark arc on the cutting torch head may

produce strong space spreading high frequency disturb signal, which may crash

the control system;

There should be shields on the controller of CNC system, and the shielding

layers should be ground connected well;

All the lines connected with CNC controller and cutting table should be shielding

wire (Such as the control wire of step motor ,limit switch etc.), and the shielding

layers should be ground connected well;

The pile of the ground cable should be connected with ground well.

6.12

Operation

1)

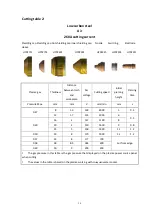

Safety note

Notes:

Operation strictly accordant with the following steps

Notice

Electric shock may hurt

or even kill man.

Cutting may cause fire or explosion

(Splashes may ignite flammable materials

nearby. Those materials should be 10m away

from the working place.

(Shut off the power during

connection

(Do not touch the conducted parts

Fume & dust is harmful.

(Do not breathe in the fume and

dust caused by cutting

(Clean up the oil spot on work

piece.

(Keep fresh air in working place

(Fume extraction equipment

Arc may hurt your eyes and skin.

(Strong arc may hurt your eyes.

(Ultraviolet radiation generated by arc may

hurt skin and eyes. Please wear shielded guard

when cutting.