Title

Rev.

Page

HMK-072

Ver1.0

P.7

2. Operation

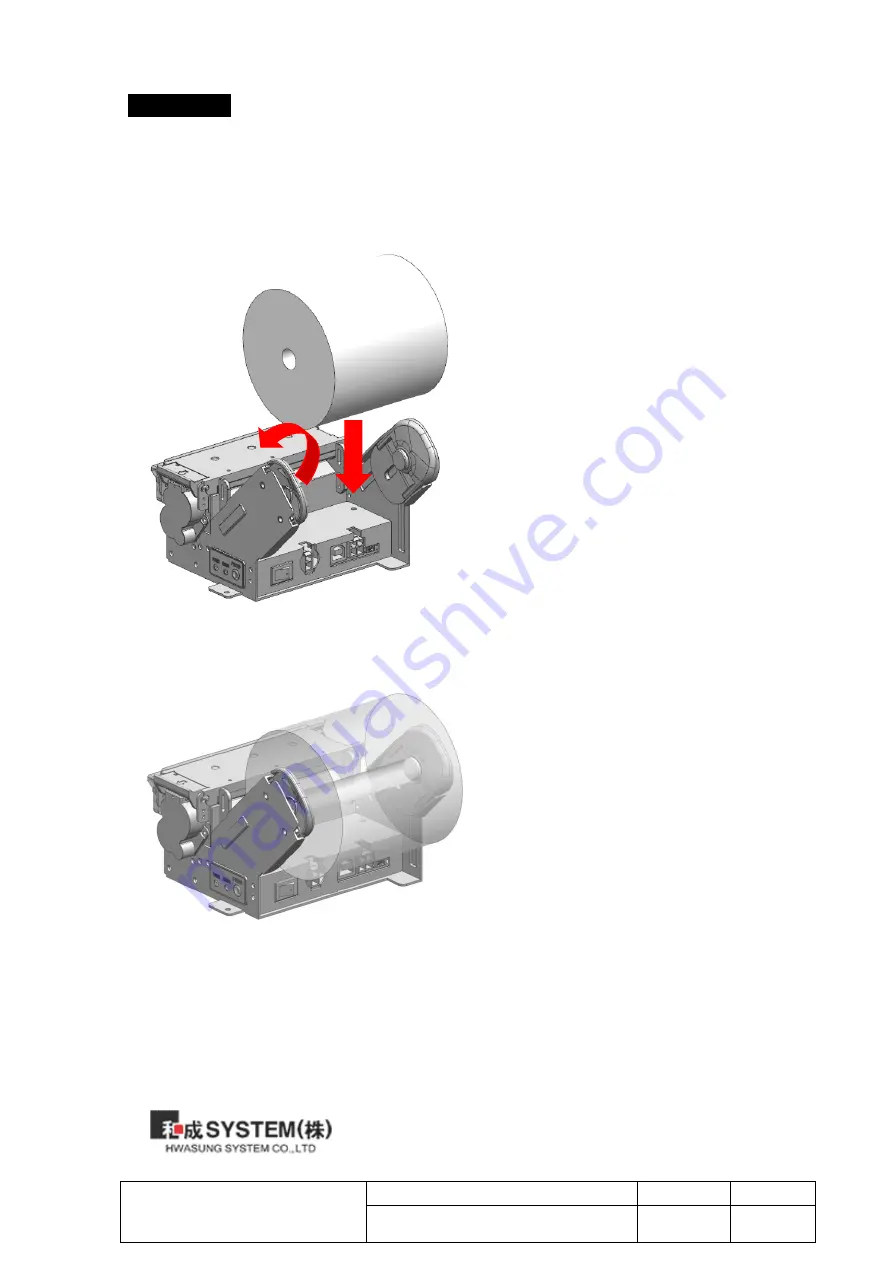

2-1) Paper Change

[Image 2-1]

[Image 2-2]

2. Release the spread Paper Lever

of Left side, then the Paper Roll is

installed.

1. Move the Paper Roll down to the Arrow

direction while spreading out the Paper Lever of

Left side, and install the Paper Roll to the Paper

Lever of Right side.

Summary of Contents for HMK-072

Page 1: ...User Manual HMK 072 ...

Page 5: ...Title Rev Page HMK 072 Ver1 0 P 4 1 2 External Dimension 1 2 1 STANDARD TYPE ...

Page 6: ...Title Rev Page HMK 072 Ver1 0 P 5 1 2 2 SHAFT TYPE ...

Page 62: ...Title Rev Page HMK 072 Ver1 0 P 61 ...

Page 68: ...Title Rev Page HMK 072 Ver1 0 P 67 No Date History Page Ver 1 2018 08 24 Created New 1 0 ...