2

ELECTRICAL SHOCK, FIRE OR EXPLOSION

HAZARD

Failure to follow this warning could result in personal

injury, death or property damage.

Before installing, modifying, or servicing system, main

electrical disconnect switch must be in the OFF position and

install a lockout tag. There may be more than one

disconnect switch. Lock out and tag switch with a suitable

warning label. Verify proper operation after servicing.

!

WARNING

This instruction covers the installation of gas conversion kit Part

No. KGAPN43012SP to convert the following furnaces from

Propane gas usage to natural gas usage. See appropriate section

for your furnace type.

Section 1

—59TP5, 925T, PG95X_T 4--Way Multipoise, Hot

Surface Ignition, 2--Stage Condensing Furnaces. This kit is

designed for use in furnaces with 40,000 through 120,000 Btuh

gas input rates.

Section 2

—58CTA, 58CTX, 312AAV, 312JAV, 33.3--in. (846

mm) High, Induced--Combustion, Hot--Surface Ignition, 2-Stage

Non-Condensing Furnaces. This kit is designed for use in

furnaces with 42,000 through 154,000 Btuh gas input rates.

DESCRIPTION AND USAGE

See Table 1 for kit contents. This kit is designed for use in the

furnaces listed in Table 2 and 4. To accommodate many different

furnace models, more parts are shipped in kit than will be needed

to complete conversion. When installation is complete, discard

extra parts.

Table 1 – KGAPN43012SP Contents

COMPONENT

NUMBER

QTY

DESCRIPTION

319965---449

1

LABEL,SHIPPING

323267---701

1

PARTS ASSY #42

323267---702

1

PARTS ASSY #43

323267---703

1

PARTS ASSY #44

323267---704

1

PARTS ASSY #45

338304---701

1

LABEL KIT

338304---702

1

LABEL KIT

AG---KGAPN2SP---XX

1

INSTRUCTIONS

EF39ZW037

2

VALVE CVRSN KIT

CA64AS001

1

PLUG, PIPE

SECTION 1

Table 2 – 35--in High Efficiency 2--Stage Condensing

Furnaces

MODEL NUMBERS BEGINNING WITH:

59TP5

925T

PG95X_T

INSTALLATION

1. Set room thermostat to lowest setting or “OFF”.

2. Remove outer doors.

3. Disconnect power at external disconnect, fuse or circuit

breaker.

4. Turn off gas at external shut-off or gas meter.

5. Remove outer doors and set aside.

6. Turn electric switch on gas valve to OFF.

MANIFOLD/ORIFICE/BURNER REMOVAL

UNIT OPERATION HAZARD

Failure to follow this caution may result in unit damage or

improper operation.

Label all wires prior to disconnection when servicing

controls.

CAUTION

!

D’EQUIPEMENT D’OPERATION

Toute erreur de câblage peut être une source de danger et de

panne.

Lors des opérations d’entretien des commandes, étiqueter

tous les fils avant de les déconnecter.

PRUDENCE

!

NOTE

: Use a back-up wrench on the gas valve to prevent the

valve from rotating on the manifold or damaging the mounting to

the burner box.

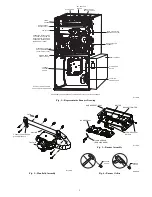

1. Disconnect the gas pipe from gas valve and remove pipe

from the furnace casing. See Fig. 1.

2. Disconnect the connector harness from gas valve Discon-

nect wires from Hot Surface Igniter (HSI) and Flame

Sensor. Disconnect the two wires from the Low Gas Pres-

sure Switch (LGPS) located on the gas valve.

3. Support the manifold and remove the 4 screws that secure

the manifold assembly to the burner box and set aside.

4. Note the location of the green/yellow wire ground wire for

re-assembly later. See Fig. 2.

5. Slide one--piece burner assembly out of slots on sides of

burner box.

6. Remove the flame sensor from the burner assembly. See

Fig. 3.

7. Remove the orifices from the manifold and discard.

ORIFICE SELECTION/DERATE

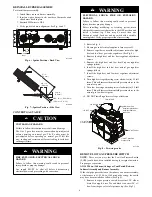

UNIT DAMAGE HAZARD

Failure to follow this caution may result in unit damage.

DO NOT re--drill burner orifices. Improper drilling may

result in burrs, out--of--round holes, etc. Obtain new orifices

if orifice size must be changed. (See Fig. 4.)

CAUTION

!