13

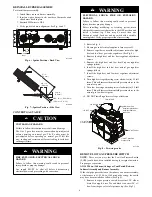

NOx DEVICE INSTALLATION (when required)

The following models must have NOx baffles installed (58CTX

and 312JAV). NOx baffles are not included in this kit and must

be ordered separately or reused if retained from original

conversion to Propane.

For NOx device installation, follow these additional steps:

1. Remove the screw underneath the heat exchanger inlet that

secures the NOx device in the heat exchanger. (See Fig.

18.)

2. Use a pair of needle nose pliers to install the NOx device.

3. Squeeze the sides of the device, if necessary, to install in

the heat exchanger.

4. Re-install screw in hole underneath heat exchanger inlet.

NOTE

: It is very IMPORTANT to reinstall the NOx bracket

mounting screw.

5. Repeat steps for each heat exchanger.

A02195

Fig. 18 -- NOx Device

ORIFICE SELECTION/DERATE

UNIT DAMAGE HAZARD

Failure to follow this caution may result in unit damage.

DO NOT re--drill burner orifices. Improper drilling may

result in burrs, out--of--round holes, etc. Obtain new orifices

if orifice size must be changed. (See Fig. 19.)

CAUTION

!

BURNER

ORIFICE

BURNER

ORIFICE

A96249

Fig. 19 -- Burner Orifice

Determine natural gas orifice size and manifold pressures for

correct input at installed altitude by using Table 5 or 6.

NOTE

: All models in all positions except Low NOx models in

downflow and horizontal positions use Table 5 (22,000 Btuh per

burner). Low NOx models in downflow or horizontal positions

must use Table 6 (21,000 Btuh per burner). See input listed on

rating plate.

1. Obtain yearly heat--value average (at installed altitude) for

local gas supply.

2. Obtain yearly specific--gravity average for local gas sup-

ply.

3. Find installation altitude in Table 5 or 6.

NOTE

: For Canada altitudes of 2000 to 4500 ft., use U.S.A.

Altitudes of 2001 to 3000 ft. in Table 5 or 6.

4. Find closest natural gas heat value and specific gravity in

Table 5 or 6.

5. Follow heat--value line and specific--gravity line to point

of intersection to find orifice size and high and low--heat

manifold pressure settings.

Furnace gas input rate on furnace rating plate is for installations at

altitudes up to 2000 ft. (610 M).

In the U.S.A

.; the input rating for altitudes above 2000 ft. (610

M) must be reduced by 4 percent for each 1000 ft. (305 M) above

sea level.

In Canada

, the input rating must be derated by 5 percent for

altitudes of 2000 ft. to 4500 ft. (610 M to 1372 M) above sea

level.

The Conversion Kit Rating Plate accounts for high altitude

derate.

INSTALL ORIFICES

1. Install main burner orifices. DO NOT use Teflon tape. Fin-

ger-tighten orifices at least one full turn to prevent

cross-threading, then tighten with wrench.

2. There are enough orifices in each kit for largest furnace.

Discard extra orifices.

NOTE

: DO NOT reinstall the manifold at this time.

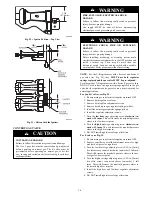

REMOVE MIXER SCREWS

NOTE

:

Each burner contains a mixer screw that must be

removed. Refer to Fig. 20 for the mixer screw location.

1. Remove the mixer screws from the burners.

NOTE

: It is not necessary to plug the hole in the burner when

the mixer screws are removed.

1.9”

(48.76 mm)

1.8”

(46.96 mm)

Location of mixer screw

that must be removed

A11501

Fig. 20 -- Mixer Screw Location