94

•

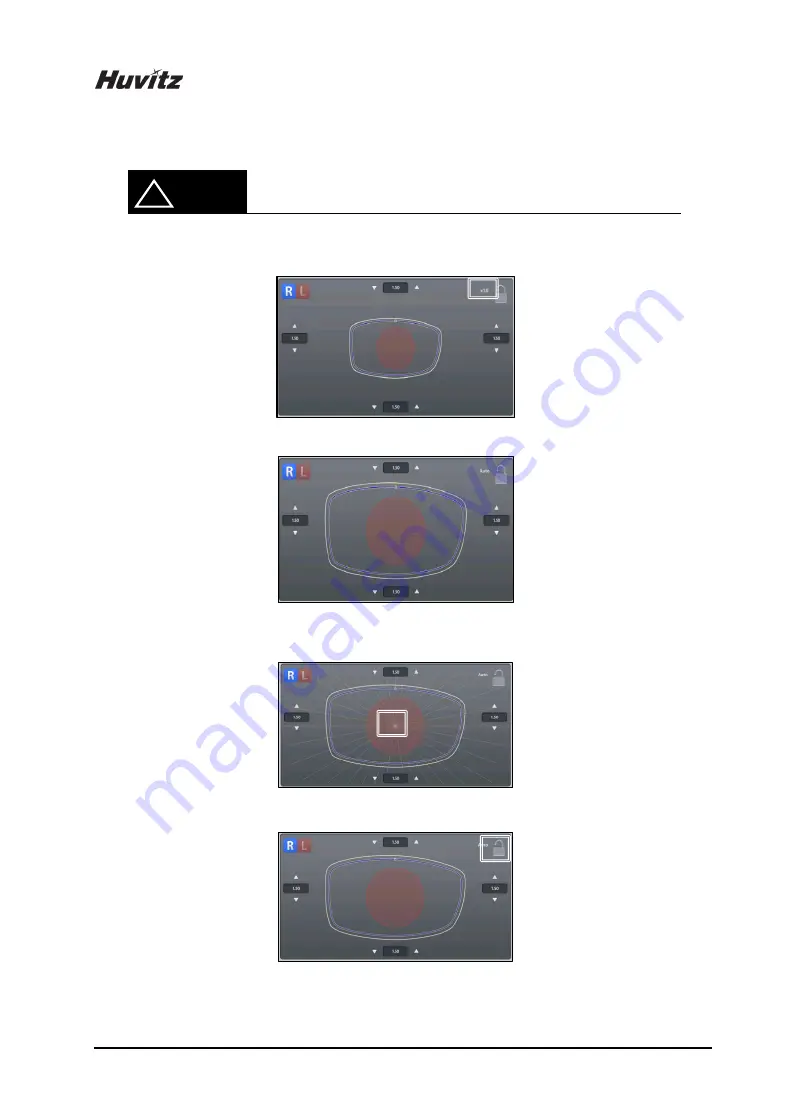

Touch the lens shape area, then the editing position moves to the touched area.

•

To see the shape in actual size, press the upper right icon.

[Actual measurement]

[Auto – Shape resized to fit to the screen)

•

Angle guideline pops up when you touch the center of the shape. (Guideline spacing - 10 °)

•

Touch screen lock button (on/off)

!

NOTE

Touch Area

Touch Area

Touch Area