8

CHANGES AND T YPING ERRORS RESERVED

CHANGES AND T YPING ERRORS RESERVED

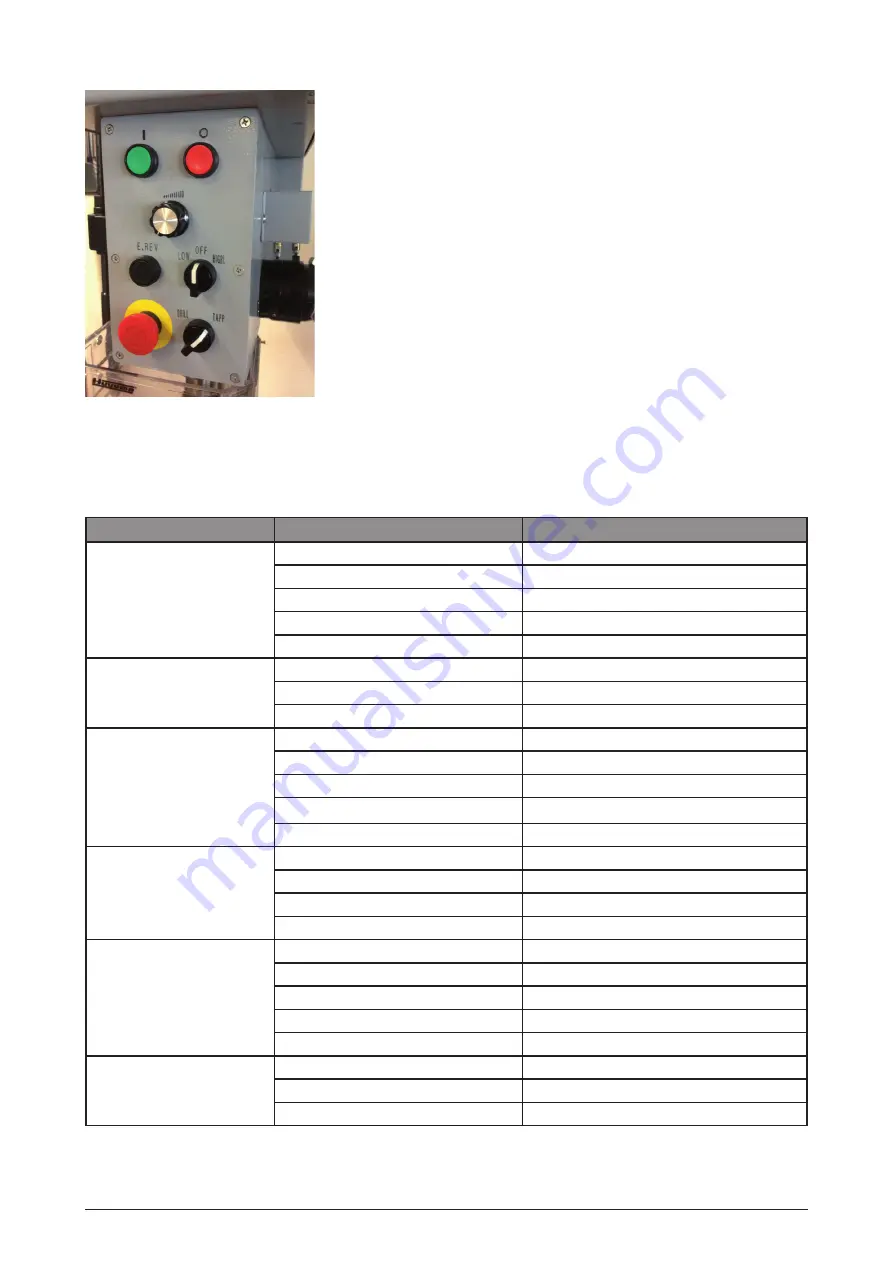

7.7 Tapping

Tapping can be done as follows:

• Turn the switch for drilling and tapping in the ‘TAPP’ position.

• Set the depth with the depth adjustment on the right-hand side of the

machine (see also 5.2).

• Turn the switch for high or low speed to ‘OFF’.

• Set the speed with the rotary speed knob.

• Move the spindle downwards with the feed handles.

When the set depth is reached, the turning direction of the spindle

automatically reverses and the spindle can be taken out of the tapping

hole.

Always use a low speed for tapping!

7.8 e.reV

buTTon

With this button you can reverse the turning direction of the spindle manually.

8. T

roubleshooTing

Problem

Possible cause

Possible solution

Too much noise

Wrong belt tension

Adjust tension

Spindle not lubricated

Remove spindle quill and lubricate

Pulley loose

Tighten pulley

V-belt loose

Adjust belt tension

Worn bearing

Exchange bearing

Play of the chuck

Drill chuck loose

Tighten by pressing chuck against table

Worn spindle shaft or bearing

Replace spindle shaft or bearing

Worn drill chuck

Replace drill chuck

Motor won't start

Power supply

Check power cord

Motor connections

Check motor connections

Switch connections

Check switch connections

Motor windings burned

Replace motor windings

Switch broken

Replace switch

Drill binds in work piece

Excessive pressure on feed handle

Apply less pressure

V-belt loose

Check belt tension

Drill chuck loose

Tighten drill with key

Speed too high

Adjust speed

Drill burns or smokes

Wrong speed

Check speed table

Chips not discharging

Clean drill

Dull drill

Check sharpness and taper

Needs lubrication

Lubricate during drilling

Wrong feed

Apply less pressure

Table difficult to raise

Needs lubrication

Lubricate with a little oil

Bent rack

Straighten

Clamp bolt locked

Loosen clamp bolt

Figure 9