English – 45

STORAGE

To ready the machine for storage, follow these

steps:

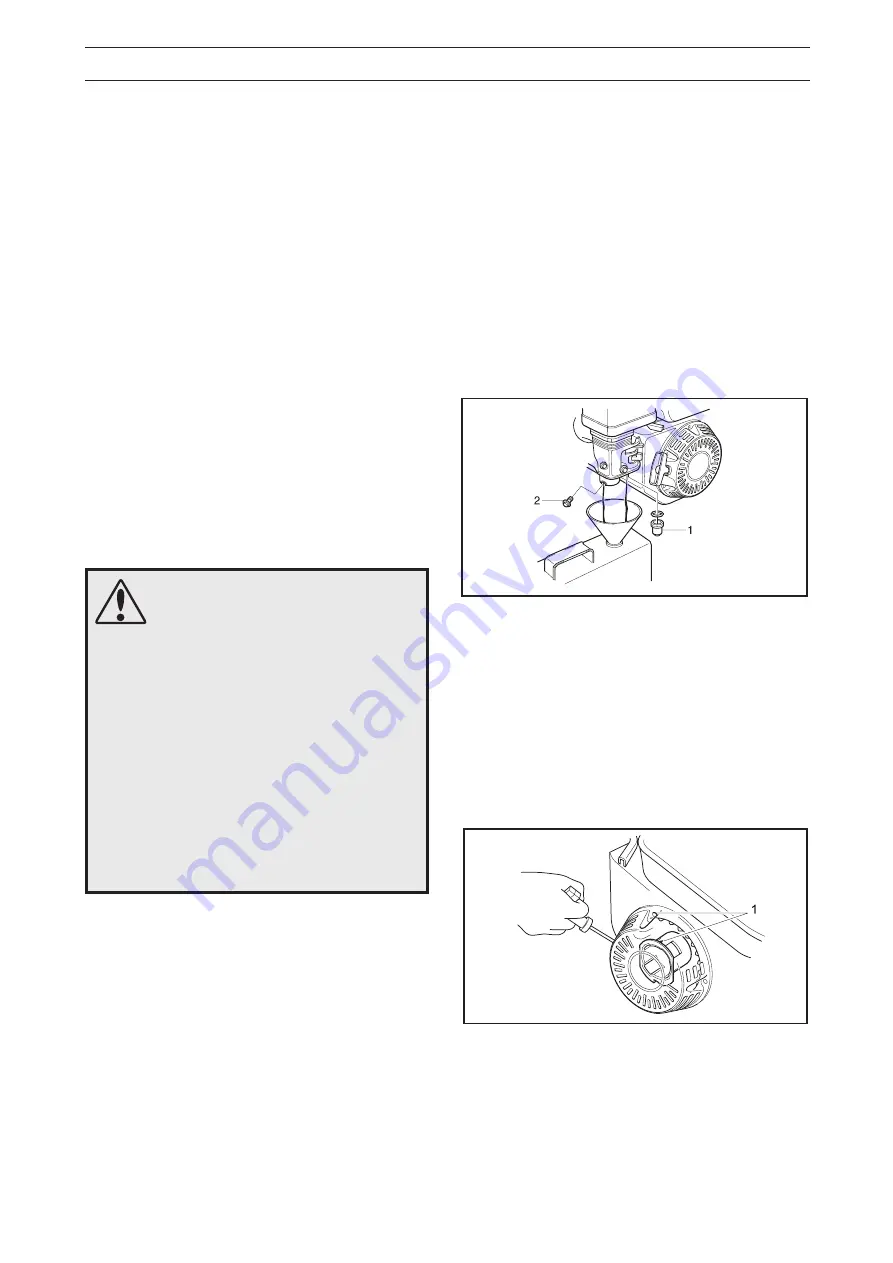

1.

Clean the machine carefully, particularly the

chassis and working equipment. Mend damage

to the paint to prevent rust.

2.

Inspect the machine for worn or damaged parts

and tighten any nuts or screws that may have

become loose.

3.

Change the engine oil; dispose of properly.

4.

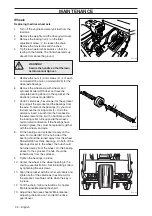

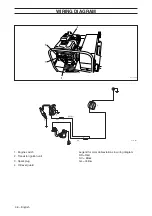

Open the fuel valve. Empty the fuel tank (1) and

the carburetor (2).

Winter storage

At the end of the season, the machine should be

readied for storage (or if it will not be in use for

longer than 30 days). Fuel allowed to stand for long

periods of time (30 days or more) can leave sticky

residues that can plug the carburetor and disrupt

engine function.

Fuel stabilizers are an acceptable option as regards

sticky residues during storage. If alkylate gasoline

(Aspen) is used, stabilizers are unnecessary

because this fuel is stable. However, you should

avoid switching between regular and alkylate

gasoline as sensitive rubber components can

harden. Add stabilizer to the fuel in the tank or in

the storage container. Always use the mixing ratios

specified by the manufacturer of the stabilizer. Run

the engine for at least 10 minutes after adding the

stabilizer so that it reaches the carburetor. Do not

empty the fuel tank and the carburetor if you have

added stabilizer.

WARNING!

Never store an engine with fuel in

the tank indoors or in poorly

ventilated spaces where fuel

vapor can come in contact with

open flame, sparks or a pilot light

such as in a boiler, hot water tank,

clothing drier, etc. Handle the fuel

with caution. It is very flammable

and careless use can cause

serious damage to person and

property. Drain the fuel into an

approved container outdoors and

far away from open flame. Never

use gasoline for cleaning. Use a

degreaser and warm water instead.

7.

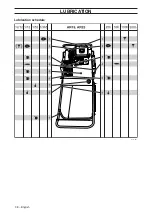

Lubricate all grease nipples, joints and shafts

as described in the chapter ”Lubrication/

Lubrication schedule”.

8.

Store the machine in a clean, dry place and

cover it for extra protection.

5.

Close the fuel valve.

6.

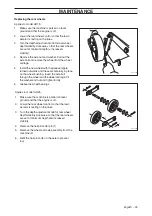

Remove the spark plug and pour about a

tablespoon of engine oil in the cylinder. Turn

over the engine so that the oil is evenly

distributed and then refit the spark plug.

Put the engine in the compression phase where

the triangle mark on the sleeve of the starter is

aligned with the upper hole in the starter.

Note: Compression phase occurs every second

revolution.

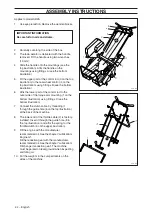

Service

When ordering spare parts, please specify the

purchase year, model, type, and serial number.

Always use genuine Husqvarna spare parts.

An annual check-up at an authorized service

workshop is a good way to ensure that your machine

performs its best the following season.

8011-049

8011-048

Summary of Contents for AR19

Page 2: ......

Page 40: ...38 English Lubrication schedule LUBRICATION 8011 280 ...

Page 52: ...50 English SERVICE JOURNAL Action Date stamp signature ...

Page 53: ...English 51 SERVICE JOURNAL Action Date stamp signature ...

Page 54: ... SERVICE JOURNAL Action Date stamp signature H r 6 ...

Page 55: ...8011 156 8011 157 8011 158 8011 159 ...

Page 56: ...2001W35 114 00 28 26 H r 6 ...