English – 35

1.

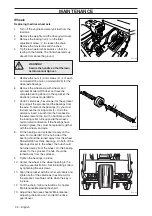

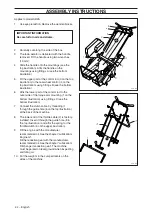

Remove the sprocket (1) by undoing the two

setscrews (when removing one side’s

freewheeling tine assembly).

2.

Remove the bearing (2) on the outside of the

freewheeling tine assembly from the rotor and

undo the locking collar (3) inside the inner

bearing. To free the locking collar, you must first

remove the setscrew and then insert a punch

into the hole beside the setscrew and tap it with

a hammer so that the locking collar turns

opposite the normal rotation direction.

3.

Remove the freewheeling tine assembly (4).

4.

Place the new rotor assembly beside the old

assembly so you can see which direction the

new tines are to be fit. You can also refer to the

tines on the fixed-tine assembly as an example

of proper assembly.

Replacing the freewheeling tine assembly

MAINTENANCE

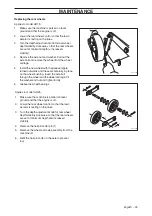

5.

The inner bearing shall be installed with the

bearing hub facing the fixed tines. Make sure

that the inner bearing has a locking collar.

6.

Once the new tines have been installed on the

rotor, you should mount the new freewheeling

tine assembly and the outer bearing. The

bearing hub should face the fixed tines. The

bearing with the locking collar faces the fixed

tines and butts up against the shoulder of the

shaft. Tighten the bearing nuts by hand.

7.

Tighten the four bearing nuts properly.

8.

Lock the bearing collar with a hammer and

punch. Make sure that the collar locks in the

same direction as the rotation of the rotor.

9.

Refit the outer shaft bearing and the rotor

assembly per instructions in steps 1 through 10

in the section ”Replacing the tine shaft bearings”

(but in reverse order).

Model AR19 has one freewheeling tine assembly at each side but model AR25 has two. The illustration above

shows model AR25.

Perform steps 1 through 10 in the previous section ”Replacing the tine shaft bearings” and then the following:

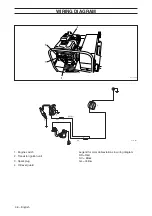

Tine wear

After your Husqvarna lawn aerator has been used for

some time, the tines will become worn out.

When this

happens, their aeration performance will diminish.

Check the tines using the drawing and replace them

before they are worn beyond their minimum length.

New tines are 12.7 cm long.

8011-171

8011-155

Summary of Contents for AR19

Page 2: ......

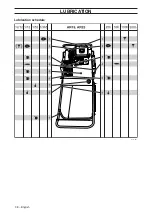

Page 40: ...38 English Lubrication schedule LUBRICATION 8011 280 ...

Page 52: ...50 English SERVICE JOURNAL Action Date stamp signature ...

Page 53: ...English 51 SERVICE JOURNAL Action Date stamp signature ...

Page 54: ... SERVICE JOURNAL Action Date stamp signature H r 6 ...

Page 55: ...8011 156 8011 157 8011 158 8011 159 ...

Page 56: ...2001W35 114 00 28 26 H r 6 ...