23

d. Any scratches on the front cap during the cutting operation must be smoothed out

using a hand grinder.

e. Install a new shank bushing after greasing. As bushings are a press, or

interference fit, heating of the front cap or cooling of the bushing will ease

installation of the bushing.

f. Install the bushing set pin and the bushing spring pin.

6. Refinishing surface scratches

(see Section 6, Page 27)

a. Cylinder and Cylinder Sleeve

Scratches on the inside surface of the cylinder should be smoothed using a flap wheel

with 240 grit and finish with 360 grit.

b. Piston

Grind off any scratches on the outside surface using a flap wheel with 240 grit and

finish with 360 grit. When polishing the piston or the cylinder bore, it is not necessary

to completely remove scratches (only the sharp edges) as this may remove excess

material. (Figures 19, 20 and 21, Page 27)

c. Main Valve and Sleeves

Main valve and sleeves cannot be polished. Replace if these parts do not slide freely

by finger pressure.

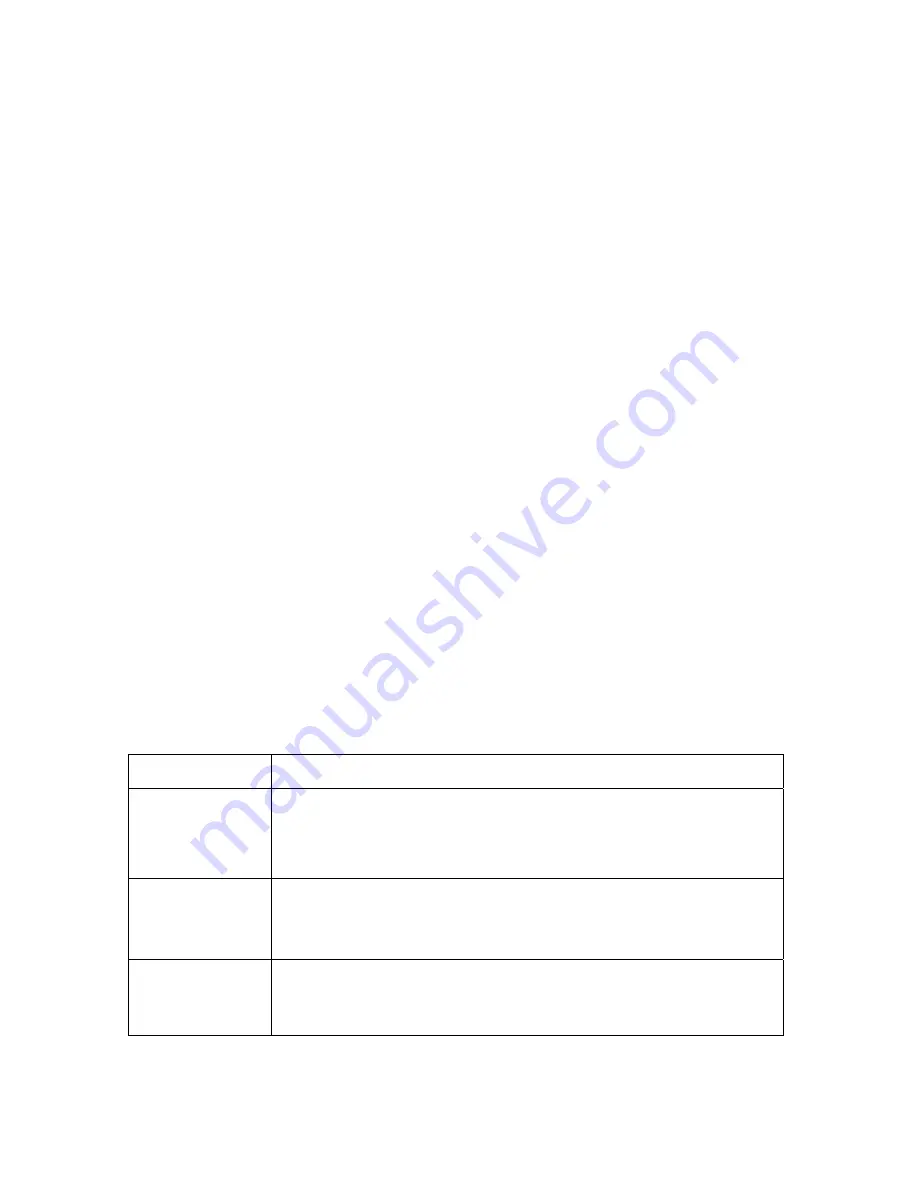

COMPONENT WEAR LIMITS

Parts are to be replaced if they are not within the wear parameters. See Table 8 and

Figure 17, for new dimensions see Table 9 page 24.

Table 8. Component Wear Limits

COMPONENT WEAR

LIMITS

Front cap

bushing

When the clearance between the tool and the front cap bushing

exceeds .200 in. (5mm), a new front cap bushing is required.

(Approximately 500 hours of use).

Shank bushing

When the clearance between the tool and the shank bushing exceeds

.160 in. (4mm), a new shank bushing is required. (Approximately

700 hours of use).

Tool

If .120 in. (3mm) of wear in the diameter is observed, a new tool is

required. (Approximately 500 hours of use). Keep tool sharp.

Summary of Contents for HH100

Page 1: ...HUSKIE HYDRAULIC HAMMERS SERVICE MANUAL HH100 HH150 2 HH300 2 HH500 2 HH750 2 HH1000 2 ...

Page 2: ...2 ...

Page 33: ...33 9 PARTS LIST AND ILLUSTRATIONS HH100 HH150 2 HH300 2 HH500 2 HH750 2 HH1000 2 ...

Page 35: ...35 HH100 HAMMER Effective 07 09 ...

Page 37: ...37 ...

Page 39: ...39 HH150 2 HAMMER S N 001 099 2B2 1000 UP Effective 07 09 ...

Page 41: ...41 ...

Page 43: ...43 HH300 2 HAMMER S N 001 099 2E2 1000 UP Effective 07 09 ...

Page 47: ......

Page 49: ...49 HH500 2 HAMMER S N 001 099 2R2 1000 UP Effective 07 09 ...

Page 55: ...55 HH750 2 HAMMER S N 001 099 2F2 1000 UP Effective 07 09 ...

Page 59: ...59 ...

Page 61: ...61 Effective 07 09 HH1000 2 HAMMER S N 001 099 2H2 1000 UP ...