4

Type of installation

Parts you must supply

Tools you must supply

ALL INSTALLATIONS

• Coaxial cable (see “Cable specifications” on

page 9)

• Weatherproof 360° cable connectors

• Cable ties

• Insulated U-shaped tacks

• F-type ground block and screws

• 1/4-inch washer (for grounding if not using RG-6

quad shielded cable)

• #6 washer (to help with drilling)

• Silicone sealant

• 8AWG aluminum and/or 14AWG copper ground

wire, as required for installation or grounding

scheme

• If not using RG-6 quad shield coaxial cable, one

split bolt with nut for connections at the ground

block

• Compass

• Angle finder or protractor

• Carpenter’s level

• Pencil or chalk

• Ladder or stepladder

• Electric drill

• Ruler and tape measure

• Adjustable wrench (socket preferred)

• Torque wrench (up to 18 ft.-lbs.)

• Open-end or socket wrenches: 3/16, 1/2, 5/16,

7/16, 9/16-inch

• Needle-nose pliers

• Lineman pliers

• String

• #2 Phillips or similar screwdriver

• Flat-blade screwdriver

• Hammer

• Permanent marker

Wood post

All parts supplied

• Drill bits: 3/8, 1/4, and 1/8-inch

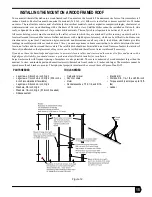

Wood frame roof

• If you decide to use 5/16-inch x 4-inch lag screws

for this installation, you must provide them and the

5/16-inch galvanized washers

• Drill bits: 3/8, 1/4, 1/8, and 5/32-inch

Concrete masonry or

concrete wall

• 3/8-inch x 3-inch Hilti sleeve anchor, Qty: 6

• If also installing optional brace kit, 1/4-inch x 2-1/4-

inch Hilti sleeve anchor, Qty: 4

• Hammer drill

• Masonry drill bits: 3/8-inch

Metal pole

• Metal pole, 2-3/8-inch diameter, 9 feet long,

schedule 40 galvanized

• 1-inch x 2-3/8-inch ground clamp for metal pole

• 40-lb. bags quick-setting concrete, Qty: 3

• If not using RG-6 quad-shielded cable, one 5/8-

inch by 10-foot ground rod and ground rod clamp

• Hole-digging tools

• Wheelbarrow or concrete mixing box

• Hacksaw

Summary of Contents for DW 3000 One-Way

Page 4: ...iv ...