Chapter 2---System Description

G1 Regulator for three CRTs

The input supply for the G1 grid of the CRTs is G1_SUPPLY and

is about -200V. The VAB regulates this supply to about -80V to -

30V. This supply can be adjusted by the G1_BIAS line. This

adjustment provides the brightness control function. The G1_BIAS

signal is an input of the VAB and is generated by the Video

Processor Board. In the event of a failure, such as lack of

deflection (a high on the /SWEEP_OK line), this output goes to the

most negative value of the input supply (about -200V).

G2 Regulator and black level adjustment for CRTs

The VAB also regulates the G2 grid of the CRTs. The supply for

the G2 grids (about 1200V) is generated by the HVPS. This

G2_SUPPLY is an input to the VAB. There are also three control

inputs (RED_G2, GRN_G2, and BLU_G2). The G2 voltage of

each CRT is adjusted individually by using these control lines.

This adjustment provides black level control. The G2 output

voltages are pulled down during shutdown mode.

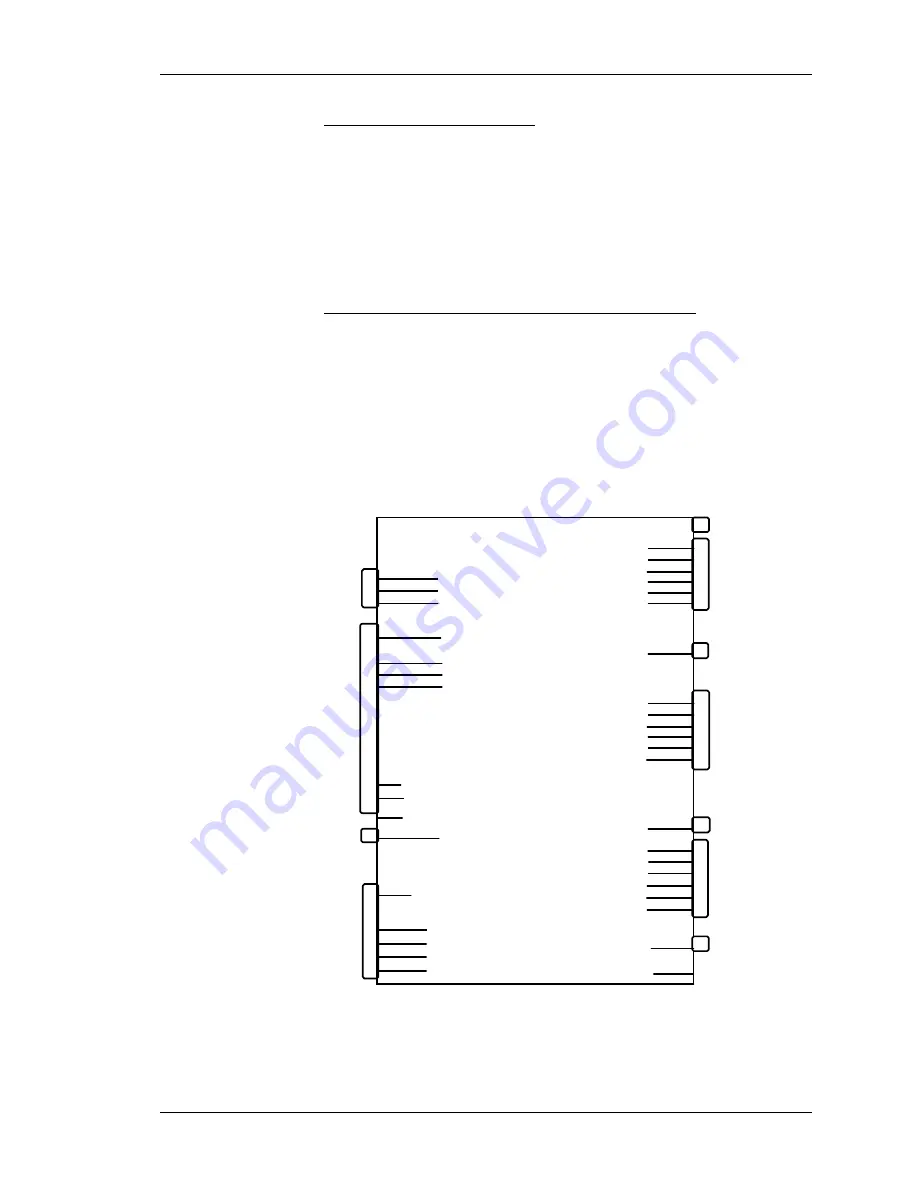

RED_VIDEO

GRN_VIDEO

BLU_VIDEO

BLANKING

G1 SUPPLY

G1 BIAS

RESTORE

ARC_GND

BLU_CATHODE

8

BLU_GRID1

9

BLU_GRID2

10

BLU_BEAM

16

BLU_HEAT-

7

B

6

ARC_GND

3

GRN _CATHODE 8

GRN _GRID1

9

GRN _GRID2

10

GRN_BEAM

14

GRN _HEAT-

7

GRN _HEAT+

6

ARC_GND

3

RED _CATHODE 8

RED _GRID1

9

RED _GRID2

10

RED_BEAM

12

RED _HEAT-

7

RED _HEAT+

6

ARC _GND

3

2

4

6

23

21

1

2

13 GRN_G2

15 BLU_G2

1 G2 SUPPLY

11 RED_G2

19 /SWEEP_OK

3 + 8OV

7 + 15V

5 + 6.2V

9 -15V

/VA_OK 18

J83

J68

J68

J85

J87

J68

J68

J84-1,

J86-1,

J88-1

J67

J68

J69

J68

From

VPB

From VPB

From HVPS

From RTG

From VPB

From

VPB

From HVPS

From HVDB

From

LVPS

To VPB

To RED

CRT

To VPB

To GRN

CRT

To VPB

To BLU

CRT

To VPB

To

HVPS

VIDEO

AMPLIFIER

BOARD

Figure 2-11

. Video Amplifier PCB, Block Diagram.

Model 220 Service Manual

2-29

Summary of Contents for 220

Page 1: ...SERVICE MANUAL Model 220 Projector ...

Page 10: ...Safety Information Model 220 Service Manual x ...

Page 14: ...Chapter 1 Introduction 1 4 Model 220 Service Manual ...

Page 119: ...Chapter 4 Maintenance Removal Replacement 4 26 Model 220 Service Manual ...

Page 129: ...Chapter 5 Troubleshooting 5 10 Model 220 Service Manual ...