212

Series Tooling Alcoa Fastening Systems

12

Equipment Required:

•

Shop airline with 90- 100 psi max.

•

Air regulator

•

Fill bottle, 120337, (supplied with tool).

•

Large flat blade screwdriver

•

Nose assembly or optional stall nut

•

Fasteners

•

Optional stall nut, 124090

Stall nut is used to load tool during bleeding

and for measuring stroke.

Preparation:

1. Install air regulator in airline and set

pressure to 20-40 psi.

2. Fill bleed bottle almost full of DEXRON II or

III - - ATF (automatic transmission fluid) - -

see

FIGURE 3

.

Procedure to Fill Empty Tool (new or rebuilt)

- - as Applicable:

1. Attach the tool air source momentarily to

seat air piston at bottom of cylinder -

- disconnect tool. With fillport facing up, lay

tool on its side.

2. With a screwdriver, remove bleed plug from

fillport.

F

ILLING AND BLEEDING PROCEDURE

Fig. 3

Fig. 3.1

WARNING

Air pressure

MUST

be set to 20 - 40

psi to prevent possible injurious high

pressure spray. Never cycle tool with-

out bleed plug tightened, fill bottle

tightened in tool, or filIport held over

a receptacle (see

FIGURE 3.1

).

When

not properly contained any fluid pres-

ent in tool will spray out. Severe

injury may result.

!

3. Screw fill bottle into fillport in the head.

4. Set airline pressure to 20 - 40 psi and

connect airline to tool.

Summary of Contents for ALCOA 212

Page 1: ...11 09 2009 HK838 INSTRUCTION MANUAL 212 PNEUDRAULIC INSTALLATION TOOL...

Page 2: ......

Page 4: ...This page is intentionally blank...

Page 8: ...212 Series Tooling Alcoa Fastening Systems 6 Fig 1 Outline Drawing...

Page 23: ...212 Series Tooling Alcoa Fastening Systems 21 Fig 5 Handle Assembly...

Page 25: ...212 Series Tooling Alcoa Fastening Systems 23 Fig 10 Piston and Gland Removal...

Page 26: ...212 Series Tooling Alcoa Fastening Systems 24 Fig 11 Piston and Gland Insertion assembly...

Page 27: ...212 Series Tooling Alcoa Fastening Systems 25 Fig 12 Gland Assembly...

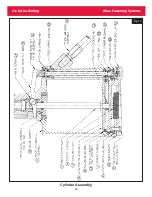

Page 28: ...212 Series Tooling Alcoa Fastening Systems 26 Fig 13 Cylinder Assembly...