256BT Pneudraulic Installation Tool

(HK1109)

Alcoa Fastening Systems

12

Equipment Required:

- Shop airline with 90 - 100 psi max.

- Air regulator

- Fill bottle, 120337, (supplied with tool).

- Large flat blade screwdriver

- Optional Stall Nut 120824

- Nose assembly

- Fasteners (Optional)

Preparation:

1. Install air regulator in

airline and set pressure to

20-40 psi.

2. Fill bleed bottle almost full

of DEXRON III - ATF or

equivalent. (Fig.6)

Refill tool only when red line on plunger drops below the

red line on the reservoir housing or when tool is rebuilt.

USE: AUTOMATIC TRANSMISSION FLUID DEXRON

III, OR EQUIVALENT.

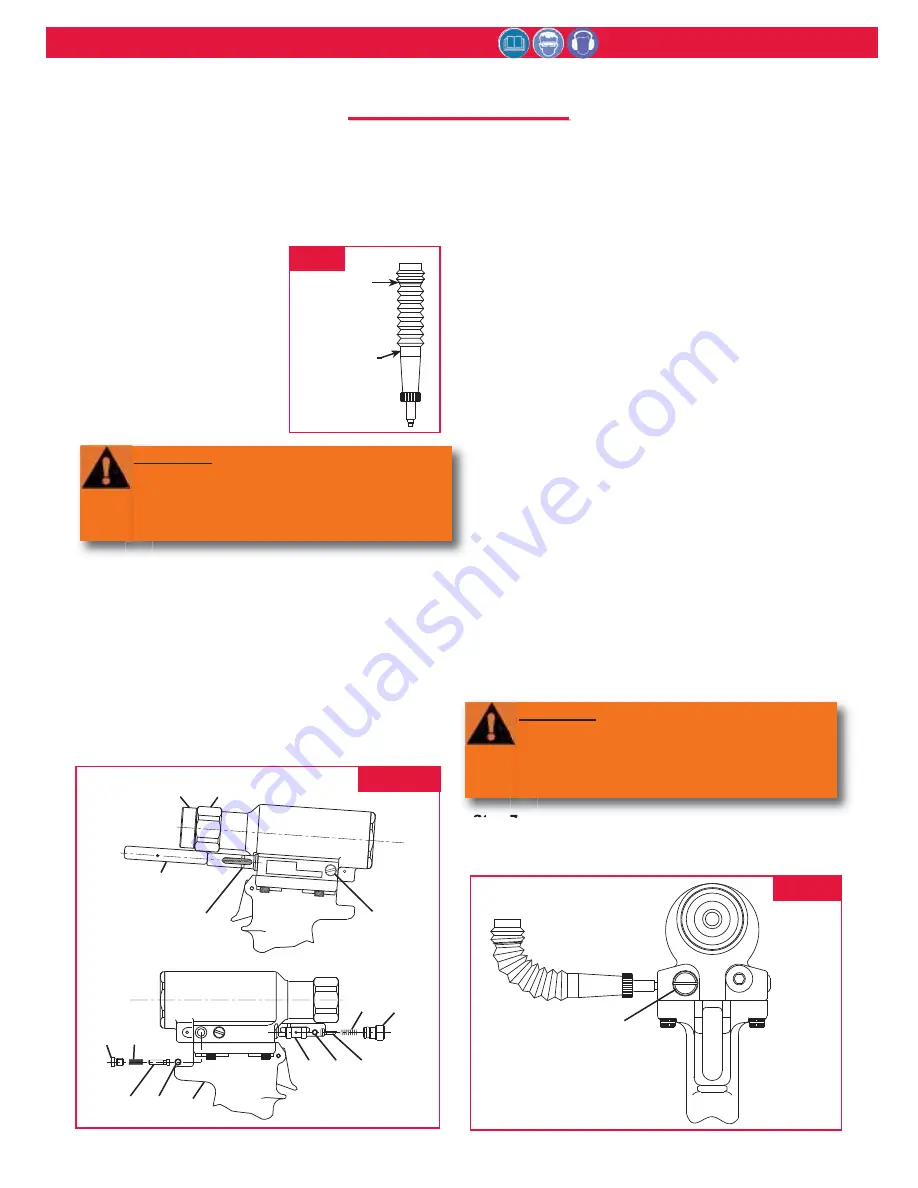

Step 1

Screw Fill Tool into Reservoir Plunger, pull Plunger into

Housing and lock Fill Tool in full forward position by

tilting handle (long side touching tool) and locking in

place. (Fig. 7)

Step 2

Remove Plugs (57) and (50) and all guides, springs and

balls from ports in head. Reinstall Plug (57) in head in

Relief Valve port (front of tool). (Fig. 7 & 8).

Step 3

Screw retaining nut onto head assembly. Screw Stall

Nut (optional see note:) onto Piston and tighten to

ensure full thread engagement. Back off retaining nut

until it engages stall nut. Check Piston location. Piston

must be all the way forward and locked with stall nut

and retaining nut.

Note:

If Stall Nut is not used, piston

must be pushed to the full forward position before

installing valves.

Step 4

Attach the tool air source momentarily to seat air piston

at bottom of cylinder. Disconnect tool. With fill port

facing up, (check valve on side) lay tool on its side.

Step 5

Install fill bottle in head fill port (check valve hole).

(Fig. 7 & 8)

Step 6

Connect tool to shop air regulated to 20 to 40 psi. Cycle

tool 20-30 times. Watch for air bubbles escaping from

the tool into bottle. (You may rock the tool to free

trapped air in the tool.) Do not allow the air to re-enter

the tool.

Step 7

When air bubbles no longer appear in bottle, remove fill

bottle while tool is lying on its side.

Stall Nut

120824

8

HUCK

U.S. PAT. 4597263

256/257

57

56

54

53

55

50

44 43

45

1

Fill Tool

Red Line

Indicator

33

FIG. 7

FILL

POINT

120337

Fill Bottle

Assembly

FIG. 6

57

FIG. 8

WARNING: Avoid contact with hydraulic

fluid. Hydraulic fluid must be disposed of

in accordance with Federal, State and Local

Regulations. Please see MSDS for

Hydraulic fluid shipped with tool.

WARNING: Air pressure MUST be set to 20

to 40 psi to prevent possible injury from

high pressure spray. If plug (50) is

removed, fill bottle must be in place before

cycling tool.

F

F

ILL

ILL

AND

AND

B

B

LEED

LEED