TP48200A-DX08A1 and TP48200A-DX08A2 Telecom

Power

User Manual

4 Maintenance

Issue 06 (2019-11-15)

Copyright © Huawei Technologies Co., Ltd.

56

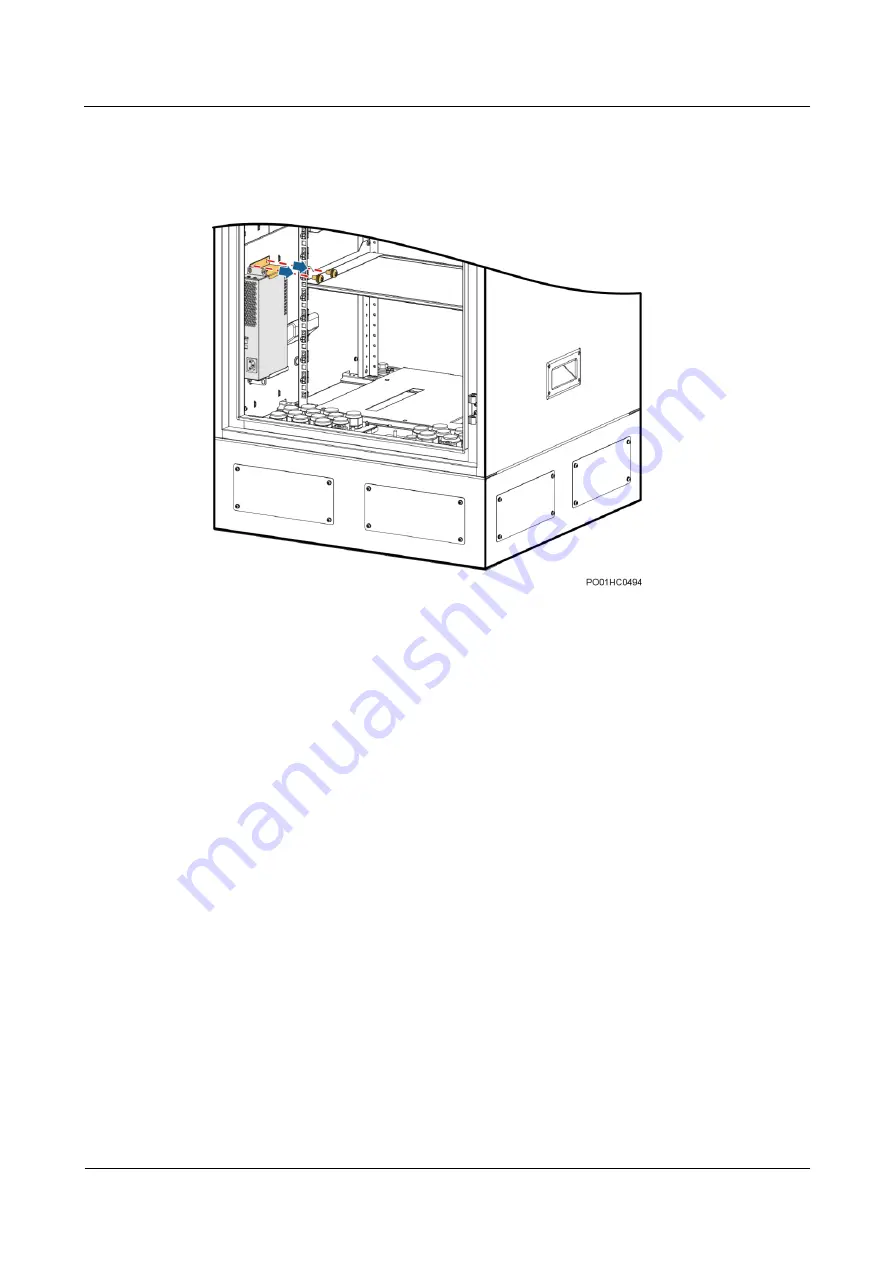

Step 4

Unscrew and remove the heater, as shown in Figure 4-16.

Figure 4-16

Removing a heater

Step 5

Place a new heater and tighten screws.

Step 6

Reconnect all the cables to the heater based on the recorded information.

Step 7

Switch on the heater circuit breaker on the AC PDU.

Step 8

Disconnect the ground cable for the ESD wrist strap, and take off the ESD wrist strap and

ESD gloves.

----End

Follow-up Procedure

Pack the removed component, and return it to the local Huawei warehouse.

4.4.10 Replacing a Battery Temperature Sensor

Prerequisites

You have obtained an ESD wrist strap, ESD gloves, an ESD box or bag, the cabinet door

key, and a tool kit.

The new battery temperature sensor is intact.

Procedure

Step 1

Connect the ground cable for the ESD wrist strap, and put on the ESD wrist strap and ESD

gloves.