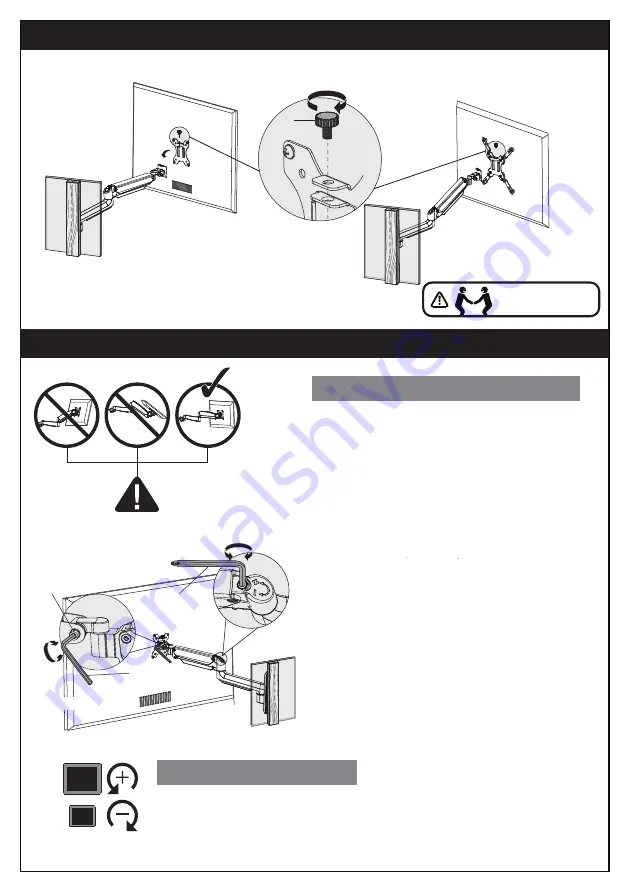

You may need

assistance with this step.

Step 4. Hang the Monitor to the Mount

I

T1

(Small Allen Key)

01

11

10

09

08

07

06

05

04

03

02

Be sure to keep the arm in horizontal

position during adjustment. Or else, it

would be difficult to adjust the mount or

damage the mount.

1. If the monitor can stay at the desired

height by itself, no adjustment needed.

2. If the monitor rises up, press the arm to

keep it in horizontal position and then use

the Allen Key [T2] to turn the bolt

clockwise(“-” direction) to reduce tension

of the arm only until the monitor can stay at

the desired height by itself.

3. If the monitor falls down, lift the arm to

keep it in horizontal position and then use

the Allen Key [T2] to turn the bolt

counter-clockwise (“+” direction) to

increase tension of the arm only until the

monitor can stay at the desired height by

itself.

Step 5. Gas Spring Tension and Tilt Adjustment

Or

Gas Spring Tension Adjustment

Gas Spring Tension Adjustment

Tilt Adjustment

Tilt Adjustment

1. Slightly loosen the pre-assembled bolt [S].

2. Adjust the monitor to your desired tilt angle.

3. re-tighten the bolt [S] to secure the monitor in place.

T2

(

Large Allen Key

)

S