lp-364 Rev. 000 Rel. 007 Date 2.12.18

13

Always consider the weight of the collector and the structural

integrity of the wall before installation. HTP requires that

installations be inspected and approved by authorized building

inspectors and comply with local and state codes BEFORE

commissioning the system. Failure to do so could result in

property damage, severe personal injury, or death.

Part 6 - Plumbing Connections

A. Temperature Sensor Insertion

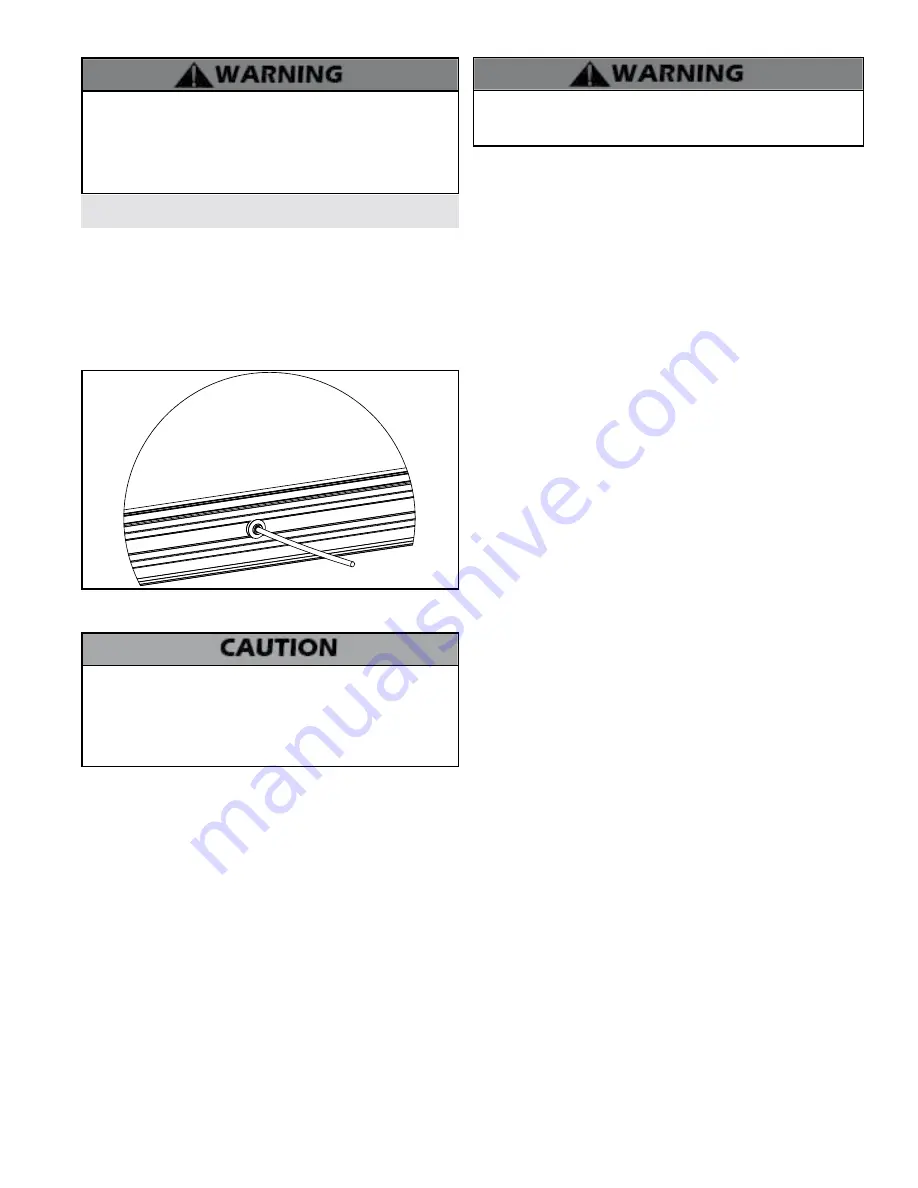

Temperature sensor wells are located on either side of the collector.

Insert the sensor into the well below the hot out port. Ensure that

the sensor and cable used on the collector are high temperature

rated (up to 395

o

F). The sensor cable should not come in direct

contact with the piping.

Ensure that any pipe insulation is watertight. Use silicone sealant to

ensure a watertight seal against the collector.

LP-364-B

01/27/17

Figure 4 - Sensor Cable Detail

B. Header Connection

Never use dielectric unions or galvanized steel fittings when

connecting to a stainless steel storage tank or heater. Use only

copper or brass fittings. Teflon thread sealant must be used on

all connections. Failure to follow this information could result in

premature product failure and property damage. Such damages

ARE NOT covered by product warranty.

Non-Galvanized Connections / Pipe Fitting

To ensure a sound seal, use plumbing thread glue or Teflon tape

approved for use in glycol based systems. Tighten using two

wrenches, taking care not to stress the copper pipe. Do not over

tighten.

Brazing/Sweating/Soldering

to the collector is acceptable, but not

recommended, as doing so can damage the header grommet. Care

must be taken to avoid exposing the silicone rubber seal to the torch

flame. Ideally, place a wet cotton cloth against the rubber seal to

prevent heat damage.

C. Air Purge

Once the inlet and outlet are connected to the plumbing system,

the collector loop should be purged of air.

1. Open Loop

For a system without an auto-air vent, a drain valve on the supply

line should be installed along with a ball valve or a metal coin vent

on the tank side. With the ball valve closed, the drain valve can be

opened to allow air to escape as water pressure forces through the

line.

When opening the drain valve, released water may be hot. Steam

may release as well. Failure to take caution when opening drain valve

could result in serious personal injury or death.

Once the drain valve no longer releases air, close it. Then open the ball

valve so normal operation may begin.

If an auto-air vent is installed on the outlet of the collector, air will

automatically eliminate from the solar line. If using a manual air vent,

open it until all air is eliminated.

2. Pressure Open Loop

Run the pump at the highest speed setting, forcing air out of the

collector and back into the tank. If an auto-air vent is installed on the

outlet of the collector, air will automatically eliminate from the solar

line. If using a manual air vent, open it until all air is eliminated.

3. Closed Loop

The solar loop may be filled with potable water or a glycol / potable

water mix, unpressurized (drain back system), or vented and

pressurized. The exact process will depend on the design of the loop

and components used.

NOTE:

A drain back system does not need to be purged.

D. Plumbing Check

Water vapor may appear on the inside of the collector glass when

initially installed. This is not a problem and will disappear after a few

days of operation. Consult your dealer or factory representative if

water vapor does not clear up after a week of sunny weather.

E. Glycol Freeze Protection

Only use food grade propylene glycol, FDA rated as GRAS (Generally

Recognized As Safe), with additives that provide resistance to

breakdown during high temperatures. Glycol pH should be checked

periodically and replaced as specified by the manufacturer.

F. Insulation

Heavily insulate all piping running to and from the collector with high

quality insulation of at least 0.6” thickness (thicker in cold climates).

Heat loss from the piping can be significant. Particular attention should

be taken to insulate any possible points of heat loss. Insulations should

have a temperature rating of 250

o

F.

Ensure the insulation is tight against the collector casing, thus

minimizing heat loss from the inlet and outlet. High quality silicone

sealant should be used to prevent water from entering the temperature

probe port and/or in between the piping and insulation foam.

Insulation foam exposed to direct sunlight should be protected against

UV related degradation by wrapping/covering with UV protective

material, such as adhesive back aluminum foil, PVC wrap, or similar.

For systems designed to allow stagnation, high temperature rated

insulation such as glass wool or mineral wool should be used on

piping close to the collector (6’). Glass wool insulation may come with

an external foil wrap, but any cuts made during installation should be

sealed with watertight, UV stabilized material, such as adhesive backed

aluminum foil or PVC wrap.

Circulating pump volumes can be a source of significant heat loss and

should be insulated. Some pumps come standard with a molded foam

casing which has good insulation properties. If the pump does not

have any insulation, the same foam insulation used on the pipe can

be used to cover the pump. This insulation should be secured in place

with good quality nylon cable ties or adhesive tape.

NOTE:

Certain pumps are not designed to be insulated. Please contact

the pump manufacturer if in doubt.

All internal and external piping should be insulated. This includes at

least the 3” closest to the hot water outlet of the tank, as this copper

pipe is a significant point of passive heat loss.