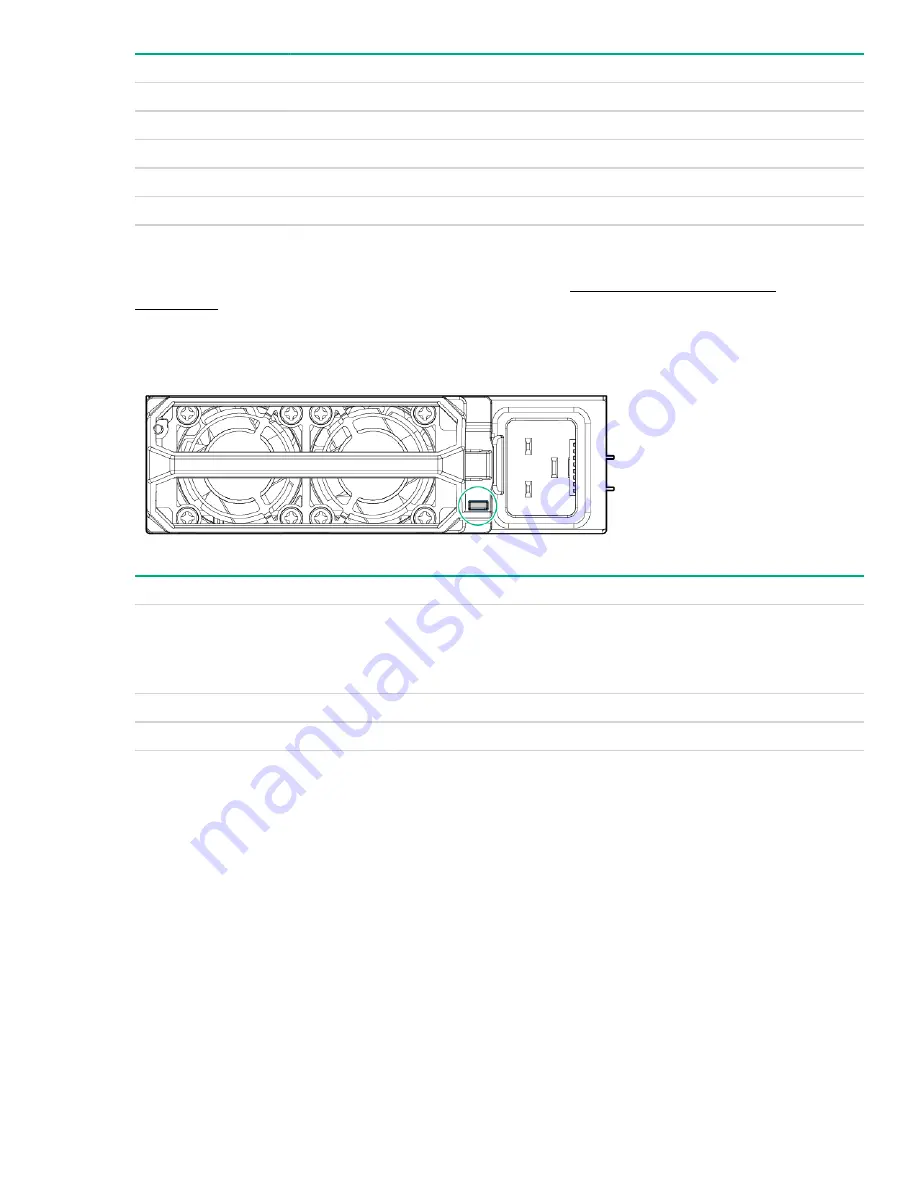

Item

Description

1

iLO network 1 link LED

2

iLO network 1 activity LED

3

Health LED

4

UID LED

5

HPE Apollo Platform Manager reset button

1

1

To reset the HPE Apollo Platform Manager, press the button. If you press and hold the button for five

seconds or longer, the APM enters recovery mode. For more information, see the

HPE Apollo Platform

Manager User Guide

on the Hewlett Packard Enterprise website (

http://www.hpe.com/support/

apm_ug_en

).

Power supply LED

Power LED

Condition

Off

1

• No input power to the power supply

• Power supply failure

Solid green

Normal operation

Flashing amber

1

Warning

1

Log in to the APM or the server iLO to check for power supply error messages.

Power supply LED

19