56

Operator's manual

M 824

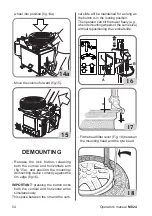

- Place the tyre on top of the wheel and

move the column into the working posi-

tion.

- Place the bottom bead under the front

of the head.

- Press the turntable control pedal to rotate

clockwise and mount the bead. Use the

rim well space, pressing onto the right

hand sidewall to reduce torsion on the

bead as the wheel rotates (fig. 23).

23

- After mounting the bottom bead, repeat

the same procedure for the top bead

(Fig. 24).

24

- Move the column forward in “not working

position”, then remove the wheel from

the tyre changer.

APPROVED UHP

AND RUN FLAT

TYRE DEMOUNTING

AND MOUNTING

PROCEDURE

For a detailed description of the UHP and

RUN FLAT tyre mounting/demounting

procedure, please refer to the instruc-

tions in the manual prepared by WDK

(German Tyre Industry Association).

INFLATION

WARNING

Inflation is a notoriously hazardous

operation. It must be carried out in ac-

cordance with the instructions provided

below.

WARNING

Noise levels may reach 85 dB(A) during

this procedure. Therefore we advise

operators to wear hearing protection

devices.

WARNING

During bead insertion and inflation, the

use of goggles and ear

protectors is

recommended.

DANGER

Although it does have a pressure

li-

miting function, the machine cannot

guarantee sufficient protection if the

tyre explodes during inflation

.

Failure to

comply with the instructions below will

render tyre inflation dangerous.

Summary of Contents for M 824

Page 16: ...Operator s manual M 824 53 EN 10 20 13 23 14 24 min 17 14...

Page 28: ...Operator s manual M 824 65 EN 32...

Page 29: ...66 Operator s manual M 824 33...

Page 30: ...Operator s manual M 824 67 EN 34...

Page 31: ...68 Operator s manual M 824 35...

Page 32: ...Operator s manual M 824 69 EN STANDARD VERSION...

Page 33: ...70 Operator s manual M 824 FS VERSION...

Page 34: ...Operator s manual M 824 71 EN STANDARD VERSION AIR MOTOR...

Page 35: ...72 Operator s manual M 824 FS VERSION AIR MOTOR...