11

EN

1. Running Mode:

Select your running mode, Forward and Reverse

without brake (F/R) is the preferred rock crawler mode. Select

Forward Reverse and Brake (F/R/B) if you want to use reverse

throttle input to control brakes.

2. Cutoff Voltage:

Low Voltage Cutoff (LVC) for Lipo Protection.

This item is mainly for preventing LiPo packs from being over-

discharged. If the LVC is enabled, the ESC will reduce the output to

50% and cut power 10 seconds later when the voltage goes below

the cutoff threshold. The red LED will begin a repeating single

flash when the ESC enters LVC.

If the LVC is disabled, the ESC will not cut off the power when the

voltage is low. We don’t recommend setting the LVC to “Disabled”

when using a LiPo pack, Without LVC it is easy for a LiPo battery to be

damaged due to over-discharge.

• NIMH - For a NiMH pack, we recommend setting this item to “Disabled.”

• Cutoff Voltage - The ESC will set the cutoff for the pack based on the

voltage the battery is at when the battery is connected.

3. RPM / Throttle Matching:

The motor RPM will change when the

vehicle encounters obstacles or terrain changes (RPM is based on

the loads on the vehicle). This setting manages how aggressively

the ESC will change the RPM under load.

When the throttle input remains unchanged, setting this item to “Low”

provides the feeling of a brushed motor. Setting it to “High” provides a

strong sense of speed-governing, making the vehicle maintain speed at

a given throttle setting regardless of the resistance.

The default setting is medium. This feature is only available in “Forward

and Reverse (rock crawler)” mode.

4. Max. Forward Force:

The power applied to the motor when the

throttle trigger is at the full throttle position. You can reduce the

value for better driving feel/control when you drive a crawler over

difficult terrain.

5. Max. Reverse Force:

The power applied to the motor when the

throttle trigger is at the full reverse position. We recommend using

a low value for most drivers.

6. Turbo Timing:

This item is adjustable from 0 degree to 10 degrees,

the value you select will initiate at full throttle. It’s usually activated

on long straightaways and makes the motor unleash its maximum

potential. Turbo timing adds a margin of power at full throttle.

7. Turbo Delay:

When “Turbo Delay” is set to “Instant”, the Turbo

Timing will be activated immediately when the throttle trigger is

moved to the full throttle position. Turbo Delay values will delay the

application of the selected Turbo Timing value.

8. Drag Brake Force:

Braking power when the throttle is at the

neutral position. Higher drag brake values are used to provide a

stronger hold or hill brakes.

IMPORTANT:

Drag brakes will consume more power and heat

will be increased, start with small values and use with caution.

Improve ventilation to ESC if heat is excessive.

9. Drag Brake Rate:

This feature manages how rapidly the ESC

applies drag brakes. Choose the drag brake rate from level 1 (very

soft) to level 9 (very aggressive); lower values ramp the brakes

slower and prevent sudden stops or jerky stopping movements.

In Auto mode, the ESC adjusts the Drag Brake Rate automatically based

on the current speed and can be helpful to prevent the vehicle from

flipping over or from sustaining drivetrain damage from harsh braking,

but also provides a sensitive braking feel at low speeds;

• The higher the current speed, the lower the drag brake rate.

• The lower the current speed, the higher the drag brake rate.

10. Neutral Range:

Adjust this parameter to your preference to

account for deadband in the throttle response. If you notice

inconsistent drag brakes, increase your Neutral Range value.

11. Start Mode/(Punch):

Set the punch from level 1 (very soft) to level

9 (very aggressive). This feature is very useful for preventing tires

from spinning. Punch levels 7 and above require high discharge

capable batteries. If the car stutters or suddenly loses power when

accelerating it may indicate the battery does not have adequate

discharge capabilities for the application. Reduce the punch value,

pinion gear size, or change to a higher C rated battery.

12. BEC Voltage:

Option 1: 6.0V Appropriate for most standard servos.

Not recommended for High Voltage (HV) servos.

• Option 2: 7.4V Appropriate for high voltage servos. Do not use

this option with standard servos; it’s possible a standard 5 – 6

Volt rated servo will be damaged at this voltage setting.

13. Motor Rotation:

Change this setting to reverse the motor rotation.

Do not change wiring order with this motor/ESC combo.

TROUBLESHOOTING

PROBLEM

POSSIBLE CAUSE

SOLUTION

The system will not connect

Your transmitter and receiver are too

close together

Move transmitter 8 to 12 feet away from receiver

You are near metal objects

Move to an area with less metal

The receiver is bound to a different

model memory

Make sure the correct model memory is active in your

transmitter

Your transmitter was placed into bind

mode and is no longer bound to your

receiver

Rebind your transmitter and receiver, and then re-calibrate

The receiver goes into failsafe a short

distance away from the transmitter

Check for damage on the receiver

antenna

Make sure your receiver antenna is protected and located

as high as practical

Replace the receiver or contact Horizon Product Support

The receiver stops responding during

operation

Low receiver battery voltage. If the

battery voltage is low, it may drop

below 3.5V momentarily, causing the

receiver to brown-out, then reconnect

Charge the receiver or vehicle battery. Spektrum receivers

require at least 3.5V to operate

Loose or damaged wires or connectors

between battery and receiver

Check the wires and connection between the battery and

receiver. Repair or replace wires and/or connectors

Vehicle does not move

Batteries are not installed properly in

the transmitter

Ensure the transmitter batteries are properly installed

Weak or no battery in the vehicle

Install a freshly charged vehicle battery

Damaged motor

Replace the motor

Frayed or broken wiring

Replace any damaged wiring

ESC is shut down by heat protection circuit Allow the ESC to cool down completely

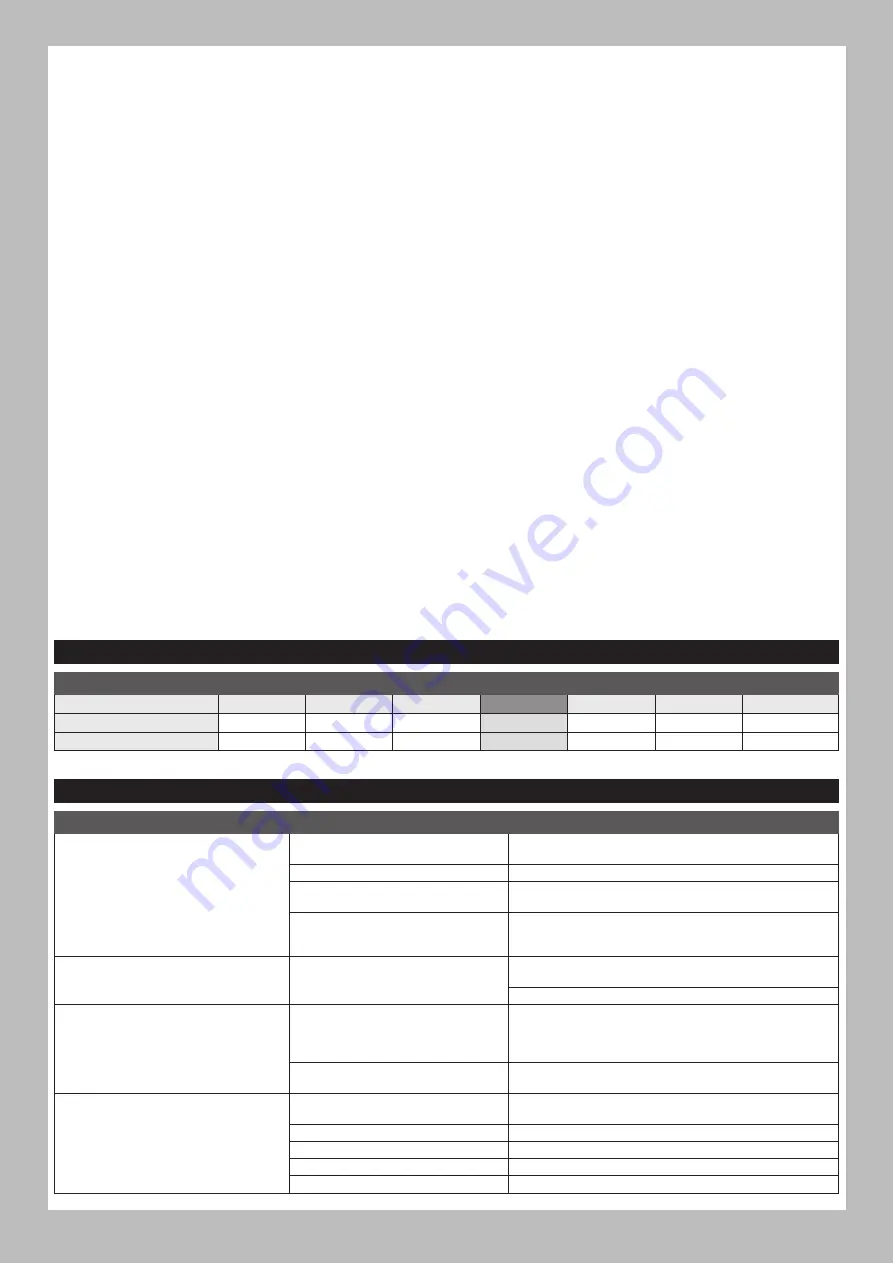

GEAR RATIOS

SPUR/PINION GEAR RATIO CHART

Pinion Size

11

12

13

14

15

16

17

Low Speed

81.47

74.68

68.94

64.01

59.75

56.01

52.72

High Speed

44.85

41.11

37.95

35.24

32.89

30.83

29.02

Standard Pinion