10

EN

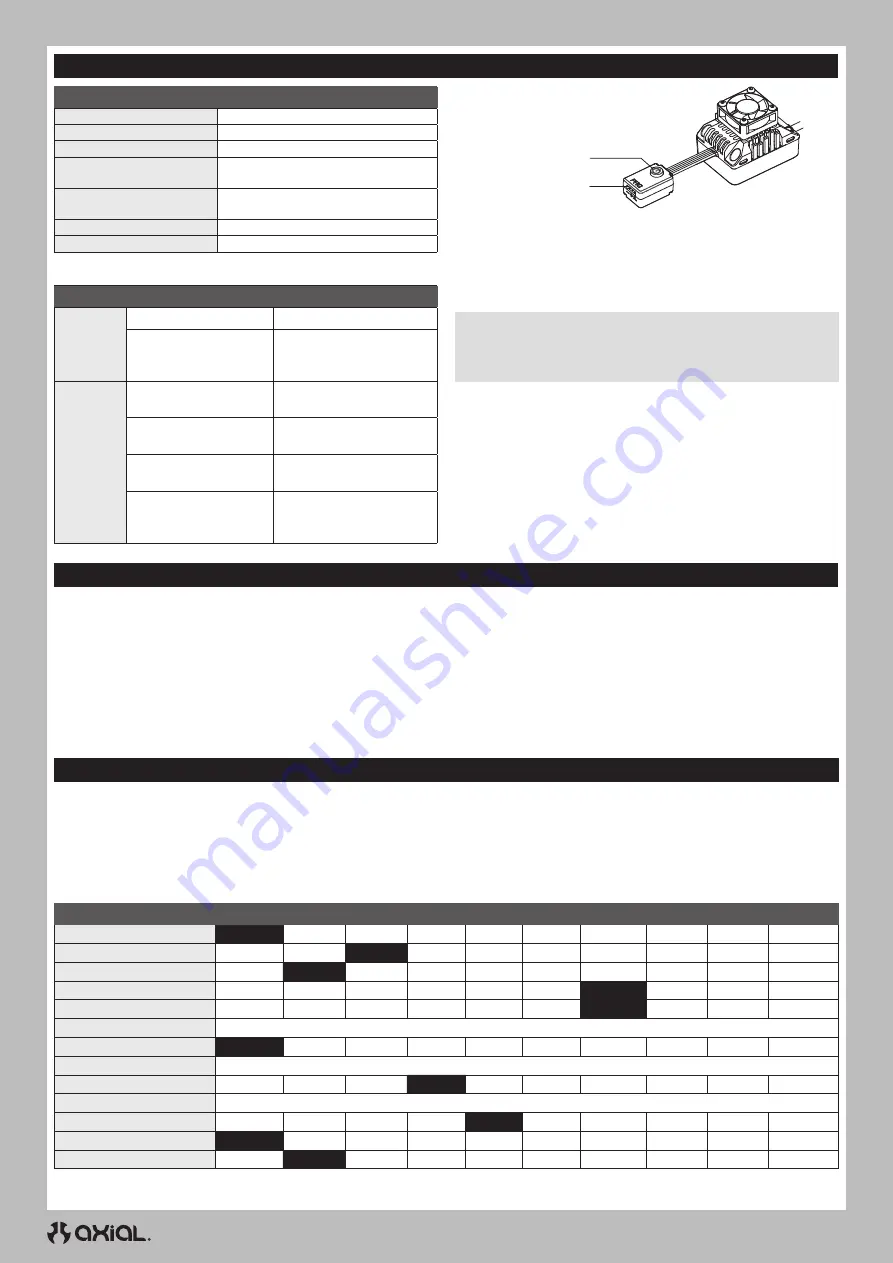

Programmable Item

Option 1

Option 2

Option 3 Option 4 Option 5 Option 6

Option 7

Option 8

Option 9

Option 10

1. Running Mode

F/R

F/R/B

2. Cutoff Voltage

Disabled

Low

Medium

High

3. RPM/ Throttle Matching

Low

Medium

High

4. Max. Forward Force

25%

37.5%

50%

62.5%

75%

87.5%

100%

5. Max. Reverse Force

25%

37.5

50%

62.5%

75%

87.5%

100%

6. Turbo Timing

0° – 10°, Adjustable in 1° Increments (0° Default)

7. Turbo Delay

Off

0.1s

0.2s

0.3s

0.4s

0.5s

8. Drag Brake Force

50% – 200%, Adjustable in 5% Increments (Default: 80%)

9. Drag Brake Rate

Level 1

Level 2

Level 3

Level 4

Level 5

Level 6

Level 7

Level 8

Level 9

Auto

10. Neutral Range

6% –17%, Adjustable in 1% Increments (Default: 10%)

11. Start Mode (Punch)

Level 1

Level 2

Level 3

Level 4

Level 5

Level 6

Level 7

Level 8

Level 9

12. BEC Voltage

6.0V

7.4V

13. Motor Rotation

CW

CCW

Blacked out cells with white lettering represent the default settings.

ESC PROGRAMMING

PROGRAMMING THE ESC WITH THE OPTIONAL SPMXCA200 SMART PROGRAMMER BOX

1. Connect the programming box to the switch.

2. Connect a battery to the ESC.

3. Power on the box and select the parameter with the SELECT button.

4. Change the values of the selected parameter with the EDIT button

5. Press the SAVE button to save the changes. The ESC requires a

power cycle to implement the saved changes.

SPECIFICATIONS

Dimensions (L × W × H)

47mm × 36mm × 24mm

Weight

4 oz (113.4g)

Max Current

120A

Voltage Range

Voltage Range

2-4S Lipo

Servo Output Voltage

(BEC)

6 or 7.4V selectable,

Continuous current of 6A

Battery Input Connector

IC5

®

(EC5

™

compatible)

Motor Connectors

5mm Bullet

* Default setting for low voltage cutoff is Li-Po.

ESC OPERATION

TRANSMITTER AND ESC CALIBRATION

The transmitter throttle neutral, forward and brake/reverse positions must be calibrated prior to ESC operation. To calibrate the transmitter and ESC:

1. Power on the transmitter.

2. Connect a fully charged battery to the ESC.

3. Press and hold the ESC power button.

4. Release the button when the red LED on the button flashes. The

red LED on the ESC will start to flash.

5. With the transmitter trigger in the neutral position, press the

ESC power button to store the neutral position. The green LED

on the ESC will flash once and the motor will emit a single tone,

indicating the neutral position has been stored.

6. Pull the transmitter trigger to full throttle, and press the ESC power

button. The green LEDon the ESC will flash twice, and the motor will

emit two tones, indicating the full throttle position has been stored.

7. Push the transmitter trigger fully forward to the full brake/reverse

position, and press the ESC power button. The green LED on the

ESC will flash three times and the motor will emit three tones,

indicating the brake/reverse position has been stored.

The ESC and motor can now be operated normally.

ESC MOTOR PAIRING

In the event the motor has been subjected to a severe impact, is

overheating or has abnormal power output, use the following process

to automatically pair the motor to the ESC:

1. Disconnect the throttle lead from the receiver.

2. Remove the pinion gear from the motor.

NOTICE:

Do not attempt to pair the ESC and motor without

removing the pinion gear from the motor. Failure to remove the

gear may result in the vehicle accelerating unexpectedly as well as

incorrect pairing.

3. Connect a fully charged battery to the ESC.

4. Press and hold the power button. The red LED on the power button

will flash, followed by a short double flash that repeats after

approximately eight seconds.

5. Release the power button.

6. The motor will automatically rotate and the green LED on the ESC

will flash. When the motor stops, the green LED will glow solid,

indicating the pairing process is complete.

7. Power off the ESC.

8. Install the pinion gear to the motor.

9. Connect the throttle lead to the receiver.

LED STATUS

INDICATION

Normal

Operation

Red and Green LEDs off

Throttle is at neutral

Red LED glows solid

Throttle is moved away

from neutral, either forward

or reverse/brake

Error

Codes

Red LED single flashes

continuously

Low voltage cutoff

activated

Green LED single flashes

continuously

ESC thermal protection

activated

Green LED double flashes

continuously

Motor thermal protection

activated

Red and Green LEDs flash

continuously

Sensor error. Check

the motor sensor wire

connection

Programming port

Power button