SV9501/SV9502/SV9601/SV9602 SMARTVALVE

TM

SYSTEM CONTROL

3

69-1270—3

Ignition system controls are set at the factory for natural

or LP gas. Do not attempt to use an ignition control made

for LP gas on a natural gas system. Do not attempt to use

an ignition control made for natural gas on an LP gas

system.

Ignition system controls with standard opening regulators

(SV9501M, SV9502M, and SV9601M) or slow opening

regulators (SV9501H and SV9502H) can be converted

between natural gas and LP gas.

Ignition system controls with step opening regulators (P

suffix) cannot be converted between gases.

Selecting the Valve

Make sure when replacing any SmartValve

TM

that you

know what valve is going in and what valve is coming out.

The SV9501 and SV9502 look slightly different from the

SV9500. The SV9500 features an ON/OFF control knob,

as shown in Fig. 1. The SV9501, SV9502, SV9602, and

SV9601 have an ON/OFF switch, as shown in Fig. 2. The

SV9501, SV9502, SV9601, and SV9602 have a

connector located at the top of the valve instead of on the

front.

The SV9501, SV9502, SV9602, and SV9601 have

identical valve body features and use the same

connectors.

NOTE: The SV9601 and the SV9602 do not have flange

mounting capability.

Fig. 1. Front view of SV9500. Notice the ON/OFF

control knob.

Location

Mount the SV9501, SV9502, SV9602, or SV9601 on the

gas manifold in the appliance.

Use of Pipe Adapters

In some field service applications, space limitations make

it difficult or impossible to thread the gas control onto the

gas supply line. This problem can be resolved for many

installations by using a pipe adapter. Install the pipe

adapter on the end of the supply line in place of the gas

control by following the same precautions and instructions

that are used for installing the gas control. After the pipe

adapter is installed, attach the gas control to the adapter.

NOTE: Using a pipe adapter increases the overall length

of the gas control.

Install Pipe Adapter to Gas Control

Install adapter to gas control as follows:

Bushings

1.

Remove seal over gas control inlet or outlet.

2.

Apply moderate amount of good quality pipe com-

pound to bushing, leaving two end threads bare.

3.

Insert bushing into gas control and carefully thread

pipe into the bushing until tight.

Installing Flange Adapters to Control

(If Required)

Mount any necessary adapters as follows:

Flanges

1.

Choose the correct flange for the application.

2.

Remove the seal over the ignition system control or

outlet.

3.

Make sure the O-ring is fitted in the flange groove. If

the O-ring is not attached or is missing, do not use

the flange.

4.

With the O-ring facing the ignition system control,

align the screw holes on the ignition system control

with the holes in the flange.

5.

Insert the screws provided with the flange.

6.

Tighten the screws firmly but do not over tighten

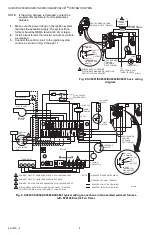

Installing Piping to Control

IMPORTANT

Do not use Teflon® tape.

All piping must comply with local codes or ordinances or

with the National Fuel Gas Code (ANSI Z223.1 NFPA No.

54), whichever applies. Tubing installation must comply

with approved standards and practices.

1.

Use new, properly reamed pipe that has no chips.

2.

Make sure the ends are square, deburred, and

clean.

3.

Make sure all tubing bends are smooth and without

deformation.

4.

Get a tube-to-pipe coupling if necessary.

5.

Run pipe or tubing to the ignition system control.

6.

Install a sediment trap in the supply line to the

ignition system control as shown in Fig. 3.

M3342A

VALVE OUTLET

FLANGE

9/64 INCH HEX SCREWS (4)