20

4.2

Replacing sensors

Removal or replacement of the

lithium battery or sensor in potentially combustible

atmospheres may compromise intrinsic safety. The

lithium battery or sensor used in the ToxiPro may

only be removed or replaced in an atmosphere that

is known to be non-hazardous.

The sensor in the ToxiPro may require periodic

replacement. To replace the sensor:

1.

Follow the directions in section 4.1 steps 1-3 to

remove the front housing.

2.

The sensor is located to the left of the LED alarm

light on the main board. Gently remove the old

sensor and install a new sensor of the same type.

3.

New sensors must be allowed to stabilize prior to

use according to the following schedule. The

detector must be powered off and functional

batteries must be installed for the sensors to

stabilize.

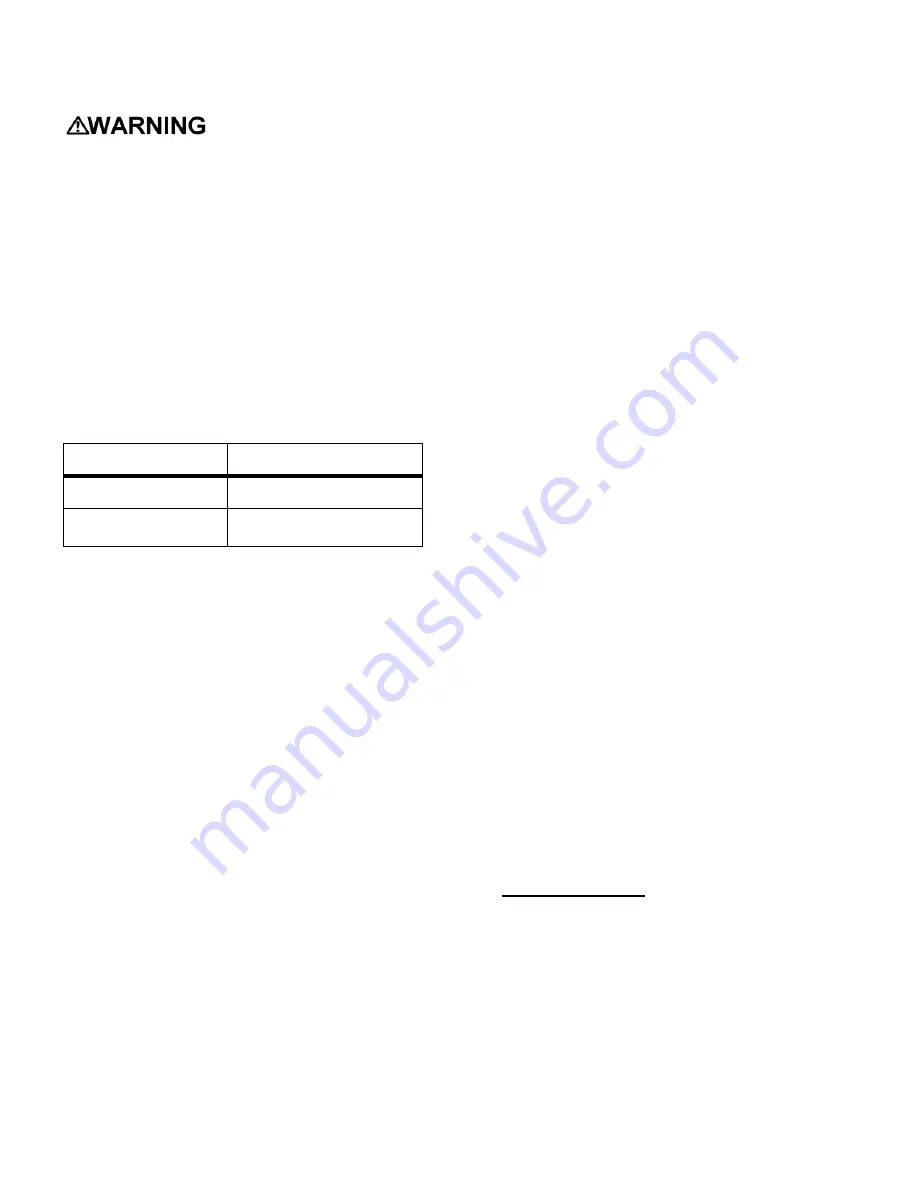

Instrument

Stabilization Period

ToxiPro O

2

1 hour

ToxiPro with toxic gas

sensor

15 minutes

4.

Once the sensor has stabilized, calibrate the

detector. For ToxiPro O

2

units, perform the Fresh

Air/Zero Calibration as described in section 3.3.

For ToxiPro units with toxic gas sensors, perform

both the Fresh Air/Zero calibration (section 3.3)

and the Span calibration (section 3.5).

Note: The ToxiPro must be calibrated after any

sensor change. See section 3.3 and 3.5 above for

details.

4.3

Proper Cleaning

The exterior surfaces of the ToxiPro may be cleaned

using a damp cloth only. Do not use cleaning agents of

any kind. The introduction of cleaning agents to the

detector may affect instrument functionality.

4.4

Storage

ToxiPro detectors may be stored for long periods in a

fresh air environment at temperatures between

10

C/50

F and 30

C/86

F.

5.

PC-Instrument

Communications

5.1

Event logging

Each ToxiPro includes a built-in event logger that stores

instrument readings during alarm conditions, calibration

values and other data. BioTrak software and an IrDA

port are necessary to download the collected data to a

PC. See section 5.3 for instructions on initiating

communications.

Warning, Danger, Custom, STEL and TWA alarms are

logged as events.

The event logger in ToxiPro version 9.20 or greater logs

will nest events. The

word “nested” in this case refers to

the logging of multiple events simultaneously. When the

instrument goes from Warning to Danger alarm condition

then both Warning and Danger alarms are being logged

as separate events.

Note: In ToxiPro versions less than 9.20 a single

event would be logged for a Danger event and

Custom alarms are not supported.

Even though latching is enabled, the event logger only

logs the actual time the instrument is in alarm condition

and not the duration for which the alarm was latched.

Since the Warning alarm level is less than/equal to the

Danger alarm level and the custom alarm level is greater

than/equal to the danger alarm level for all sensors

except oxygen, the sequence of these events usually is

Warning -> Danger -> Custom.

When the instrument goes into a warning alarm

condition the event logger starts recording data for the

warning event. When the instrument goes into danger

alarm condition, since the gas level is still greater than

the warning condition the event logger is logging data for

both warning and danger alarms. And when the

instrument goes into the custom alarm condition the

event logger is then logging data for 3 different event

types: - warning, danger and custom. When the gas

level goes drops below custom alarm level the custom

event would finish first, followed by the danger and then

warning.

For oxygen units the custom alarm value is always less

than the danger alarm. So the sequence of events would

be danger->custom. STEL and TWA events are not

valid for an oxygen instrument.

Eventlogger Capacity

The capacity of the event logger is 100 events. If the

capacity is exceeded, the memory will “wrap”. The word

“wrap” refers to deleting the oldest event and replace it

with the newest event. It is recommend to download the

instrument’s datalogger on a regular basis to prevent

data loss due to wrapping.