2

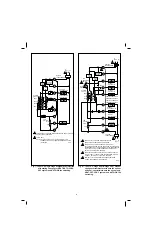

Fig. 2—Mounting subbase on wall.

Fig. 3—Restrict wiring to recessed area surrounding

terminals.

WIRING

All wiring must comply with local electrical codes and

ordinances.

Disconnect power before wiring to prevent electrical

shock or equipment damage.

The shape of the terminal barrier permits insertion of

straight or conventional wraparound wiring connections.

Either method is acceptable.

Push excess wire back into the hole, and plug hole with

nonhardening caulk, putty or insulation to prevent drafts

from affecting thermostat operation.

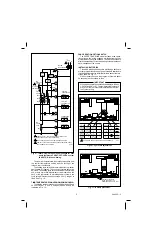

Refer to Figs. 4-9 for typical hookups of subbase thermo-

stat.

NOTE: Restrict all wiring to recessed area surrounding

terminals (Fig.3) to assure thermostat/subbase contact.

ADJUSTING CYCLE RATE

To custom-tailor the thermostat’s cycling performance

to different types of heating equipment, cycle rate adjust-

ment screws are provided on the back of the thermostat.

Correct setting of these screws will provide optimum room

temperature control.

NOTE: MOST APPLICATIONS WILL NOT REQUIRE A

CHANGE IN CYCLE RATE.

Fig. 4—T8621A 1-stage heat/1-stage cool thermostat

with HEAT-AUTO-COOL-OFF system and

AUTO-ON fan switching.

WIRES THROUGH

WALL OPENING

WALL

WALL

ANCHORS

(2)

SUBBASE

MOUNTING

HOLES

MOUNTING

SCREWS (2)

M846

FOR STRAIGHT

INSERTION –

STRIP 5/16 in. (8 mm)

FOR WRAPAROUND –

STRIP 7/16 in. (11 mm)

RESTRICT

WIRING TO

THIS AREA

KEEP WIRING BELOW

THIS SURFACE

TOP SURFACE

OF SUBBASE

FRONT VIEW OF

TERMINAL AREA

CROSS-SECTIONAL VIEW OF

TERMINAL AREA

M847

M1574

HEATING

TRANSFORMER

R

C

W1

HEAT RELAY

COOLING

TRANSFORMER

Y1

G

RC

COOLING

CONTACTOR

FAN RELAY

HIGH

LIMIT

L1

(HOT)

L2

HEAT

AUTO

OFF

SYSTEM

SWITCH

AUTO

ON

FAN

SWITCH

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD

PROTECTION AS REQUIRED.

FOR SINGLE TRANSFORMER SYSTEM JUMPER R AND RC.

NOMINAL 24 Vac POWER MUST BE PRESENT BETWEEN R AND C FOR

THERMOSTAT OPERATION.

COOL

H

POWER

SUPPLY

2

1

C

L1

(HOT)

L2

1

2

3

2

3