P7810A-D PRESSURETROL® CONTROLLER

65-0268—1

10

1.

Record the original location of the Limit setpoint knob.

Make sure that the Limit setpoint knob is set (moved to)

a lower value than the Maximum Fixed Stop Limit Value

setpoint. The green LED will be reflective of the call for

heat status and the yellow LED will blink slowly.

IMPORTANT

Do not decrease the Limit Setpoint knob far enough

to cause a lockout.

2.

Very slowly increase the Limit setpoint knob until the

yellow LED begins to blink fast. The current position of

the Limit setpoint now represents the Maximum Fixed

Stop Limit Value setpoint stored in memory.

3.

Return the Limit setpoint knob to the original location

(step

1

).

Setting High Limit Set Point (P7810C,D)

After the Maximum Fixed Stop Limit Value has been stored

into memory, adjust the Limit Setpoint knob to the desired

pressure value at which safety shutdown (lockout) will occur

when the vessel pressure exceeds this setpoint value.

NOTE: The High Limit setpoint value can be less than or

equal to the Maximum Fixed Stop Limit Value but

cannot be set to a value higher than the Maximum

Fixed Stop Limit Value.

Pressure On/Off Control (P7810A,B,C,D)

Adjust the setpoint and differential using the potentiometer

knobs on the front of the controller. The differential is a

subtractive value from the setpoint adjustment. The upper

operating point is determined by the control setpoint, while the

lower operating point is determined by the control range

setting (control setpoint minus the differential setting).

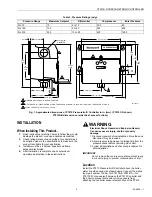

Set the potentiometer knobs to the desired point by aligning

the center of the arrow on the potentiometer knob with the

desired mark on the scale plate. See Fig. 13.

Yellow light emitting diode (LED) ON constantly indicates

power applied; green LED On indicates closed contact or call

for heat.

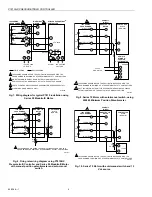

Modulate Control (P7810B,C Only)

The P7810B,C adds 4 to 20 mA modulation output and uses

two additional potentiometers. The pressure sensor output is

fed to an error and gain amplifier to perform the modulation

determined by the control potentiometer settings.

The potentiometer knobs mounted on the P7810B,C face

adjust the current output for a given set of pressures.

The modulation range is an additive value to the modulation

setpoint value.

LED Display (Tables 7 and 8)

The yellow LED is always lit with power applied to the P7810

Pressuretrol® Controller. The microprocessor changes the

brightness of the yellow LED to indicate normal operation,

turns the green LED on and off to indicate call for heat status

and flashes both LEDs to indicate a fault.

NOTE: The term “flashing” means on/off/on/off for the green

LED and bright/dim/bright/dim for the yellow LED.

Press and hold the Reset Switch to access internal

diagnostics. The green (right) LED will flash a series of long

followed by a series of short flashes. Count the long and short

flashes and check the fault code table (Table 8) for

information. For example: four long and three short flashes is

code 43. If you miss the code the first time, keep holding the

Reset Switch down and the code will repeat. Letting go of the

Reset Switch clears the fault information and resets the

P7810.

Table 7. P7810 Blink Codes.

Yellow

Green Control

State

Off

Off

Device off.

No LEDs blinking

Device on, Central Processing Unit (CPU) malfunction.

Slow Blink

Off

Run mode, output off, Limit potentiometer setpoint used.

Slow Blink

On

Run mode, output on, Limit potentiometer setpoint used.

Fast Blink

Off

Run mode, output off, Internal Maximum Fixed Stop Value setting

used.

Fast Blink

On

Run mode, output on, Internal Maximum Fixed Stop Value setting

used.

Alternating Fast Blinks

Lockout, output off, high limit exceeded, Alarm output engaged.

Simultaneous Fast Blinks

Lockout, output off, internal fault, Alarm output engaged.

On, Bright

Fast Blink

Output off, internal Maximum Fixed Stop Value setting not set.