2

Installation Instructions / OmniAssure Touch Square

Subject to change without notice.

1

Scope of delivery

1 Installation instructions

1 Reader front

1 Mounting backplate

5 Wall anchors (5 x 25 mm or #8 x 1”)

5 Screws (panhead, 3 x 30 mm or #4 x 1¼”)

3 Enclosure screws (metric, M2 x 5 mm panhead)

4 Enclosure screw caps

2

General

The OmniAssure Touch Square Reader was tested at the panels:

– NetAXS 123 V6 (Wiegand)

– ProWatch 6k (Wiegand)

– Pro32 (Wiegand)

– Mercury EP1502 (OSDP)

Mobile credentials:

– proX (EM4102)

– MIFARE classic

– MIFARE DESFire EV1/EV2

– OmniAssure OES

– QKey

– HID

– ISO-SNR Quadrakey

– Bluetooth Low Energy

Physical interfaces:

– Wiegand

– RS-485 (OSDP 2.1.7.)

The Reader Utility Application is used to configure:

– credential bit formats and length

3

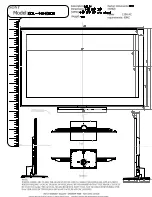

Installation

All dimensions in drawings are in mm.

NOTE

All wiring shall be in accordance with applicable codes

and regulations. Observe applicable building codes and

safety regulations in determining the reader position.

UL 294: Installation must be done in accordance with

National Electrical Code, ANSI/NFPA 70.

General terms

– The reader base can be used as a drilling template where necessary.

– When positioning the reader base, ensure that the backtamper can

be securely screwed in; otherwise the tamper detection is reduced to

opening monitoring.

– We recommend that the connection cable of the reader is guided

through the reader base from the side with the lettering reading "Hon-

eywell" before fixing the reader base.

– Secure the reader base without exerting excessive force.

– Use the mounting material included in the accessories. If you need

more materials, ensure that these have the same diameter.

–

The power supply of the reader must be switched off while the

reader is connected. Risk of damage!

3.1

Important notes on mounting

– Pay attention to the

minimum distances

(

).

Mounting readers in close proximity of each other will reduce perfor-

mance, the minimum recommended mounting distance side-by-side

or back-to-back is 125 mm (5”).

– Mounting the reader on a metal surface may reduce performance, a

plastic separator of at least 6 mm (¼”) is recommended.

3.1.1 Mounting height

In order to operate the keypad and read the indications optimally, install

the reader at a height of 130 to 140 cm (51 to 55”) above the floor.

3.1.2 Necessary cable reserve

In order for the reader to be able to dismounted when necessary, there

must be a sufficient cable reserve in the direct vicinity of the reader.

Depending on the type of mounting, the cable reserve can be placed in

the flush mounted socket, or in a nearby junction box.

3.1.3 Outdoor use

– If the reader is to be used outdoors, the cable entry must be sealed

on both sides of the wall, to prevent condensation.

– The connector for the connection cable of the reader should be

located indoors.

3.2

Mounting for flush mounted wiring

Screw the reader base onto a DIN-style f.m. socket [1] (preferred mount-

ing) or directly onto the wall. For sockets from Switzerland, the reader is

fixed at the corners.

Screw the backtamper [2] onto the wall, so that if the reader is torn off the

wall, the actuator pin [3] remains secured to the wall, thus releasing the

cover contact and signalling a tamper situation.

3.3

Mounting for surface mounted wiring with wall plate

Place the wall plate for surface mounting [4] (Item no. LU45BB) between

the reader base [5] and the wall and screw both firmly onto the wall. Then

screw on the tear-off protection (see chapter "Mounting for flush mounted

wiring").

The wall plate can be rotated in 90° steps so that the surface mounted

cable entry [6] can be from at the bottom, at the top, on the left or right.

3.4

Mounting with Visual Cover

The visual cover (item no. OT4XBHONG/OT4WHONG) is suitable for

flush wiring and surface wiring.

The mounting is identical to the mounting with the wall plate.

Note that the visual cover cannot be rotated. For this reason, a surface

mounted cable entry [7] is therefore only possible from below or above.

Break [8] if necessary.

For a lateral cable entry, it is therefore necessary to provide the wall plate

under the sight protection.

3.5

Fasten the reader

[9] Hang the reader from above in the reader base.

[10] Snap shut below.

[11] Close with the two attached screws.

After completing the mounting and functional testing seal the housing.

To do this, press the enclosed seals into screw holes.