ML7425A,B SPRING RETURN ELECTRIC LINEAR VALVE ACTUATOR

63-2518-3

5

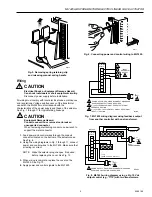

Fig. 5. Removing spring retaining clip

and releasing manual spring handle.

Wiring

CAUTION

Electrical Shock or Equipment Damage Hazard.

Can shock individuals or short equipment circuitry.

Disconnect power supply before installation.

All wiring must comply with local electrical codes, ordinances

and regulations. Voltage and frequency of the transformer

used with the ML7425 must correspond with the

characteristics of the power supply and those of the actuator.

See Fig. 7 through 11 for typical wiring hookups.

CAUTION

Equipment Damage Hazard.

Conduit connection or removal can break an

unsupported connector.

When removing or attaching conduit, use a wrench to

support the metal connector.

1. Feed power and control wires through the conduit

connector located on the bottom of the actuator case.

See Fig. 6.

2. Using the wiring diagrams in Fig. 7 through 11, connect

power and control wires to the ML7425. Make sure that

all wiring is correct.

NOTE:

Make the selector plug changes, if required,

before replacing the cover. See Fig. 12.

3. When wiring is complete, replace the cover on the

ML7425. See Fig. 13.

4. Apply power and control signals to the ML7425.

M6629

Fig. 6. Connecting power and control wiring to ML7425.

M6630

Fig. 7. ML7425 wiring diagram using feedback output

from another controller with one transformer.

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND

OVERLOAD PROTECTION AS REQUIRED.

F

+

0-10 Vdc OR 2-10 Vdc CONTROL SIGNAL. SEE SIGNAL

INPUT (+) SECTION.

2-10 Vdc FEEDBACK SIGNAL. SEE OUTPUT SIGNAL

FEEDBACK SECTION.

ML7425

WIRING

STRIP

F

+

–

T2

T1

O1

O2

TS

1

3

2

INPUT

(FEEDBACK)

OUTPUT

3

2

1

L1

(HOT)

L2

–

C8286B

Fig. 8. ML7425 wiring diagram using a 2 to 10 Vdc

output control (e.g., T775) with two transformers.

L1

(HOT)

L2

1

1

WIRING

STRIP

F

+

–

T2

T1

O1

O2

TS

1

1

2

2

3

3

4

5

6

L1

(HOT)

L2

1

ML7425

T775

(WITH 2-10 VDC OUTPUT)

DUAL

TRANSFORMERS

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND

OVERLOAD PROTECTION AS REQUIRED.

M7894

SENSOR