Reference Data

Release 3

34-ST-25-20 MC Toolkit User Manual

79

9/06

Honeywell HART Fields and Values

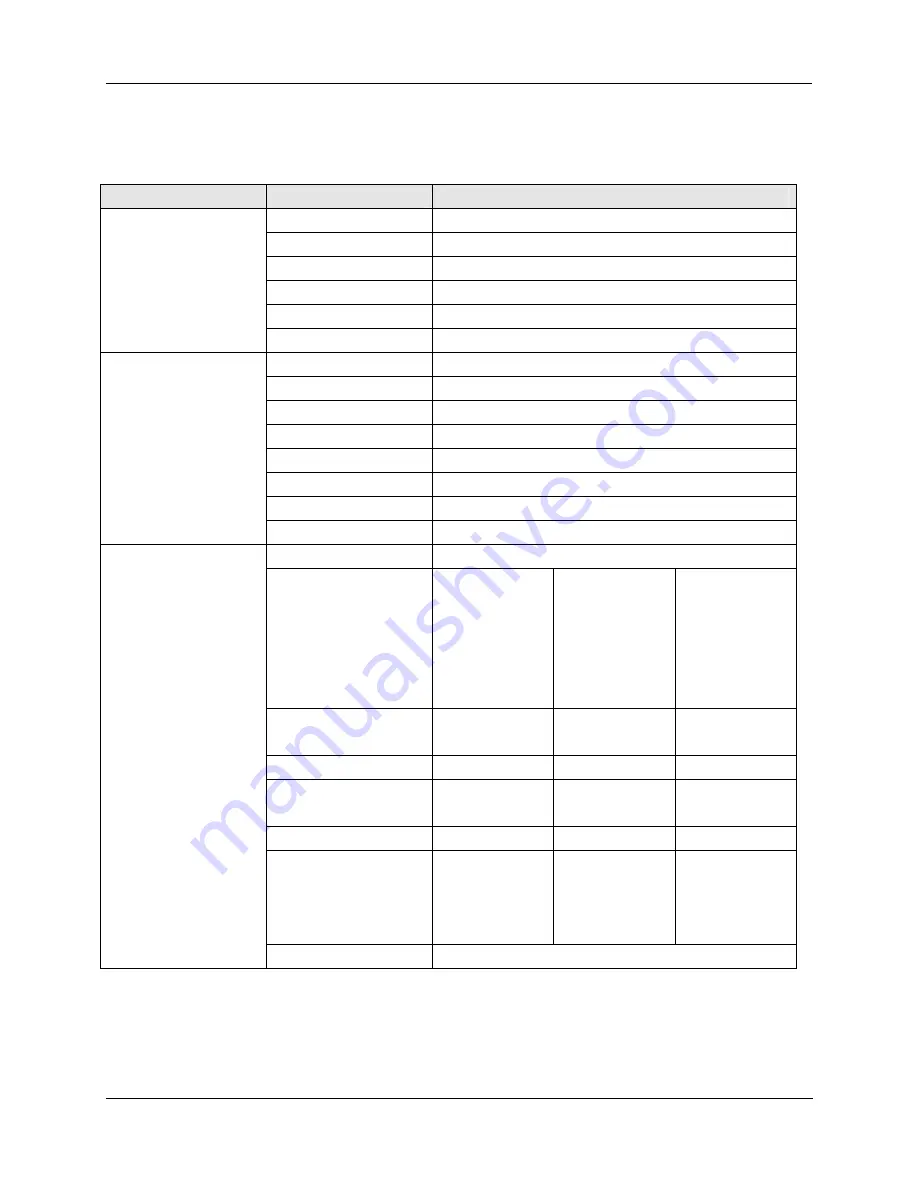

Table 27 HART Fields and Values

Dialog

Field

Value

Device Info

Tag ID

8 chars

Model

Transmitter

type

Device ID

Transmitter’s device ID

Manufacturer

String

Message

32

chars

Descriptor

16

chars

Extended Info

Universal Rev.

Numerical

Software

Rev.

Numerical

Field Device Rev.

Numerical

Poll

Address

Numerical

#

Req.

Preams

Numerical

PV

Sensor

S/N

Numerical

Final Assembly #

Numerical

PROM

ID

Numerical

Basic Setup

LRL, URL, LRV, URV

Floating point

PV Sensor Units (ST

only)

InH2O @ 68F

InHg @ 0C

FtH2O @ 68F

MmH2O @ 68F

MmHg @ 0C

Psi

Bar

Mbar

g/cm²

kg/cm²

pascals

kPa

Torr

ATM

InH2O @ 60F

MPa

InH2O @ 4C

MmH2O @ 4C

PV Sensor Units

(STT only)

°C

°F

°R

Kelvin

MV

Ohms

Sensor Type (ST only)

DP

AP

GP

SV

Units

°C

°F

°R Kelvin

Transfer Function

Linear

Square root

Damping (ST only)

0.00

0.16

0.32

0.48

1.00

2.00

4.00

8.00

16.0

32.0

Damping (STT only)

Floating point between 0 and 100