Calibration

4-12

SVP Controller Operation Manual

Part No.: 44200004 - Revision 2

4.4 Gravimetric Water Draw

Equipment

1. Water draw kit: Contact Honeywell Enraf representative or factory

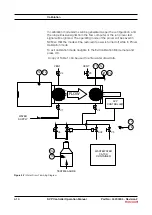

directly to obtain a water draw kit, Figure 4-6.

2. Precision electronic weigh scales of the correct size and resolution: for

example for an S25 prover, balance must have a capacity of at least

100kg and +/-4 gram (200 lb. and +/- 0.01 lb.). resolution. (1 part out

of 20,000 or better resolution). For proper scale verification prior to the

gravimetric water draw refer to API 4.9.4.

3. Certified test weight set: ANSI/ASTM Class 3 equivalent or better.

4. Source of air-free or deaerated deionized or distilled water with

approximately 38 Lpm at 172-690 kPag (10 GPM at 25-100 psig)

steady, non-fluctuating, pressure.

5. A volume catch container ideally, large enough for the volume of fluid

dispensed by the prover. Container must be designed to be placed on

the precision balance or scales.

6. Certified high resolution pressure gauge: 0-690 kPag (0-100 psig).

7. Three traceable thermometers with 0.1°C (0.2°F) graduations

(for thermometer reference positions see Figure 4-7).

8. Water draw data sheet, Table 2.

9. Water overboard container, volume to be at least as large as

test measure.

Note:

Honeywell Enraf Water Draw P&T kit or equivalent assembly eases

installation of water draw prover instrumentation. The Honeywell

Enraf Water Draw P&T kit consists of four traceable temperature

thermometers (one spare thermometer included) and one pressure

gauge. All thermometers come with the calibration certifications

if ordered from Honeywell Enraf.

Procedure

Water draw notes:

Perform steps 14 – 21 at least twice prior to taking data to purge the

system of air, assure the temperature is stable, and to get familiar with

the procedure.

Repeat water draw procedure until at least 3 consecutive draws repeat

within 0.02% or other repeatability criteria that the certifying parties agree

upon. The flow rate on at least one run must vary by 25% to assure

integrity of prover seals and absence of leakage.

Failure to achieve the necessary repeatability may be caused by leaking

valves, air in the system, varying pressure, leaking seals, or faulty

calibration technique.