4

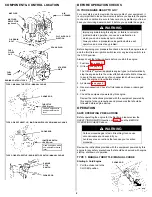

TYPE 3: FIXED THROTTLE / ENGINE STOP SWITCH /

MANUAL CHOKE

Starting A Cold Engine

1. Pull the choke rod to the

CLOSED position.

2. Move the engine stop switch

to the ON position.

Some engine applications

use a remotely-mounted

ignition switch rather than the

engine-mounted engine stop

switch shown here.

3. Pull the starter grip lightly until

resistance is felt, then pull

briskly.

NOTICE

Do not allow the starter grip to

snap back against the engine.

Return it gently to prevent

damage to the starter.

4. If the choke rod was pulled to

the CLOSED position to start

the engine, push it to the OPEN

position as soon as the engine

warms up enough to run

smoothly.

5. The engine speed is preset on this type.

Starting a Warm Engine

If the engine has run out of fuel, pull the choke rod to the CLOSED

position after refueling. If the engine has not run out of fuel, leave the

choke rod in the OPEN position.

1. Pull the starter grip lightly until you feel resistance, then pull briskly.

2. If the choke was pulled to the CLOSED position to start, push it to

the OPEN position as soon as the engine starts.

Stopping The Engine

Move the engine stop switch to the OFF position.

OIL ALERT

®

SYSTEM

The Oil Alert system is designed to prevent engine damage caused by

an insufficient amount of oil in the crankcase. Before the oil level in the

crankcase can fall below a safe limit, the Oil Alert system will

automatically stop the engine [the throttle lever (ignition switch lever)

will remain in a run position].

If the engine stops and will not restart, check the engine oil level

(page 5) before troubleshooting in other areas.

SERVICING YOUR ENGINE

THE IMPORTANCE OF MAINTENANCE

Good maintenance is essential for safe, economical and trouble-free

operation. It will also help reduce pollution.

To help you properly care for your engine, the following pages include

a maintenance schedule, routine inspection procedures, and simple

maintenance procedures using basic hand tools. Other service tasks

that are more difficult, or require special tools, are best handled by

professionals and are normally performed by a Honda technician or

other qualified mechanic.

The maintenance schedule applies to normal operating conditions. If

you operate your engine under severe conditions, such as sustained

high-load or high-temperature operation, or use in unusually wet or

dusty conditions, consult your servicing dealer for recommendations

applicable to your individual needs and use.

Maintenance, replacement, or repair of the emission control

devices and systems may be performed by any engine repair

establishment or individual, using parts that are “certified” to

EPA standards.

MAINTENANCE SAFETY

Some of the most important safety precautions follow. However, we

cannot warn you of every conceivable hazard that can arise in

performing maintenance. Only you can decide whether or not you

should perform a given task.

SAFETY PRECAUTIONS

• Make sure the engine is off before you begin any maintenance or

repairs. This will eliminate several potential hazards:

–

Carbon monoxide poisoning from engine exhaust

.

Be sure there is adequate ventilation whenever you operate

the engine.

–

Burns from hot parts

.

Let the engine and exhaust system cool before touching.

–

Injury from moving parts

.

Do not run the engine unless instructed to do so.

• Read the instructions before you begin, and make sure you have

the tools and skills required.

• To reduce the possibility of fire or explosion, be careful when

working around gasoline. Use only a nonflammable solvent, not

gasoline, to clean parts. Keep cigarettes, sparks and flames away

from all fuel related parts.

Remember that an authorized Honda servicing dealer knows your

engine best and is fully equipped to maintain and repair it.

To ensure the best quality and reliability, use only new genuine Honda

parts or their equivalents for repair and replacement.

CHOKE ROD

ON

ENGINE

STOP

SWITCH

OFF

STARTER GRIP

WARNING

Improper maintenance, or failure to correct a problem

before operation, can cause a malfunction in which you

can be seriously hurt or killed.

Always follow the inspection and maintenance

recommendations and schedules in this owner’s manual.

WARNING

Failure to properly follow maintenance instructions and

precautions can cause you to be seriously hurt or killed.

Always follow the procedures and precautions in this

owner’s manual.