2

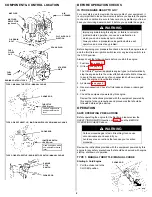

COMPONENT & CONTROL LOCATION

BEFORE OPERATION CHECKS

IS YOUR ENGINE READY TO GO?

For your safety, and to maximize the service life of your equipment, it

is very important to take a few moments before you operate the engine

to check its condition. Be sure to take care of any problem you find, or

have your servicing dealer correct it, before you operate the engine.

Before beginning your preoperation checks, be sure the engine is level

and the throttle lever (ignition switch lever or engine stop switch) is in

the STOP position.

Always check the following items before you start the engine:

The Oil Alert

®

system (applicable engine types) will automatically

stop the engine before the oil level falls below safe limits. However,

to avoid the inconvenience of an unexpected shutdown, always

check the engine oil level before startup.

4. General inspection: Check for fluid leaks and loose or damaged

parts.

5. Check the equipment powered by this engine.

Review the instructions provided with the equipment powered by

this engine for any precautions and procedures that should be

followed before engine startup.

OPERATION

SAFE OPERATING PRECAUTIONS

Before operating the engine for the first time, please review the

SAFETY INFORMATION

BEFORE

OPERATION CHECKS

above.

Review the instructions provided with the equipment powered by this

engine for any safety precautions that should be observed with engine

startup, shutdown or operation.

TYPE 1: MANUAL THROTTLE / MANUAL CHOKE

Starting A Cold Engine

1. Pull the choke rod to the

CLOSED position.

STARTER

GRIP

SPARK PLUG

OIL FILLER CAP/

DIPSTICK

MUFFLER

AIR

CLEANER

FUEL

TANK

THROTTLE

LEVER (gray)

CHOKE ROD

MUFFLER

DEFLECTOR

(optional)

IGNITION SWITCH

LEVER (red)

Used on engines with a

non-adjustable throttle

lever.

Used on engines with

an adjustable throttle

lever.

ENGINE

STOP

SWITCH

CHOKE ROD

FUEL

FILLER

CAP

ENGINE CONTROL TYPES

OIL DRAIN

BOLT

TYPE 1: MANUAL THROTTLE / MANUAL CHOKE

TYPE 2: FIXED THROTTLE / IGNITION SWITCH LEVER / MANUAL CHOKE

TYPE 3: FIXED THROTTLE / ENGINE STOP SWITCH / MANUAL CHOKE

CHOKE ROD

WARNING

Improperly maintaining this engine, or failure to correct a

problem before operation, can cause a malfunction in

which you can be seriously hurt or killed.

Always perform a preoperation inspection before each

operation, and correct any problem.

WARNING

Carbon monoxide gas is toxic. Breathing it can cause

unconsciousness and even kill you.

Avoid any areas or actions that expose you to carbon

monoxide.

CHOKE ROD