11

3.3. Operating Conditions

Maximum liquid temperature:

35°C, short term up to

60°C.

Density of pumped liquid:

max. 1100 kg/m

3

Ph-value of pumped liquid:

6 up to 8.

Level of pumped liquid:

The lowest level must always be

above the top of the pump housing (volute).

Operation:

The motors are designed for continuous op-

eration (S1) with fully submerged motor, maximum 15

starts per hour. Our standard warranty and maintenance

regulations refer to intermittent operation. For reduced

warranty periods and service intervals due to continuous

operating conditions please contact our service

department.

3.4. Explosive Environments

For operation of the pumps in explosive environments

only models with explosion-proof motors must be used

(see HOMA product range).

4. Warranty

Our warranty only covers pumps which are installed and

operated in accordance with these installation and opera-

tion instructions and accepted codes of good practice and

being used for the applications mentioned in these instruc-

tions.

5. Transport and Storage

Never use the cable or the discharge hose/pipe to lift,

lower, transport or attach the pump. Always use the han-

dle or a rope or a chain attached to the handle.

The pump may be transported and stored in vertical

or horizontal position. Make sure that it cannot roll or fall

over. For longer periods of storage, the pump should be

protected against moisture, frost or heat.

6. Electrical Connection

Before operation, an expert check must secure that

the required electrical protection measures exist. The

connection to ground, earthing, isolating transformer, fault

current breaker or fault voltags circuit must correspond to

the guidelines set forth by the responsible power plant.

The voltage required in the technical data sheet

must correspond to the existing line voltage.

Submersible pumps used outside of buildings must

have a cable with a minimum length of 10m.

Make sure that the electrical pin-and-socket connec-

tions are installed flood- and moisture-safe. Before start-

ing operation check the cable and the plug against dam-

ages.

The end of the pump power supply cable must not be

submerged in order to prevent water from penetrating

through the cable into the motor.

The normal separate motor starter/control box of

standard as well as of explosion proof pumps must

not be installed in explosive enviroments.

The pumps will be delivered with cable and plug. Control

boxes (e.g. for twin pump stations) are available from the

HOMA accessory program. If any other control unit is

used, make sure that the thermal relay in the motor starter

is set according to the nominal current consumption of the

pump motor (see data on the pump label).

7. Installation

Pay attention to the maximum depth of immersion

(see pump label).

If the pump is installed in a sump, the sump opening

must be covered with a tread-safe cover after installation.

The operator has to prevent damage through the

flooding of rooms caused by defects of the pump through

the use of appropriate measures (e.g. installation of alarm

units, backup pump or like that).

7.1. Submerged Base Stand Installation

The pump may be installed with a flexible discharge hose

or a rigid pipe, non-return valve and isolating valve. If a

flexible hose is used, make sure that the hose has the

same diameter like the pump discharge and does not

buckle.

Please make sure that couplings or rigid pipe at the top of

the discharge connector does not block the integrated

non-return valve. The pump will not obtain the full capacity

if the non-return valve is blocked.

Fix a rope or a chain to the pump handle and lower the

pump into the liquid. If the pump is installed on muddy

ground, support it on bricks to prevent it from sinking in.

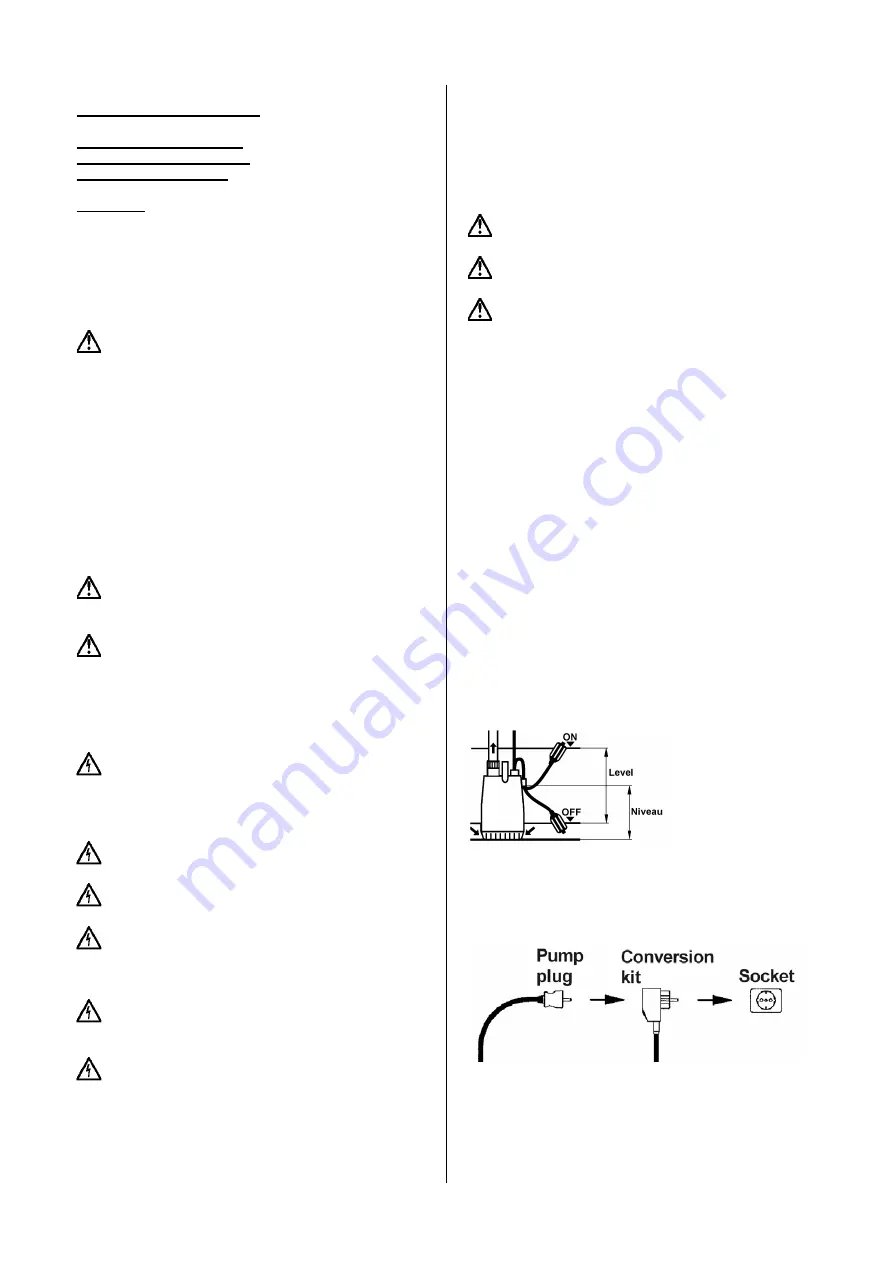

7.2. Automatic Float Switch Control

( only model CR 252 WA )

Pumps supplied with a float switch start and stop auto-

matically according to the liquid level in the pit automati-

cally.

Both the distance be-

tween start level (on)

and stop level (off) of

the pump and the

level of the fixing

point of the float

switch can be ad-

justed.

7.3. Automatic Float Switch Conversion Unit

Pumps without a float switch can be fitted with a float

switch conversion kit subsequently. Fit the conversion kit

between the mains supply and the pump plug.

When installing the conversion kit, never place the float

switch in the sump without fixing the float switch cable to a

fixed point in the sump, because for operation the float

switch must rotate around the fixing point of the cable.

Non-observance may cause an overflow (pump does not

start) or damage of the pump (pump does not stop).