Holms DUO

© HOLMS INDUSTRI AB, ALL RIGHTS RESERVED 150603.

19

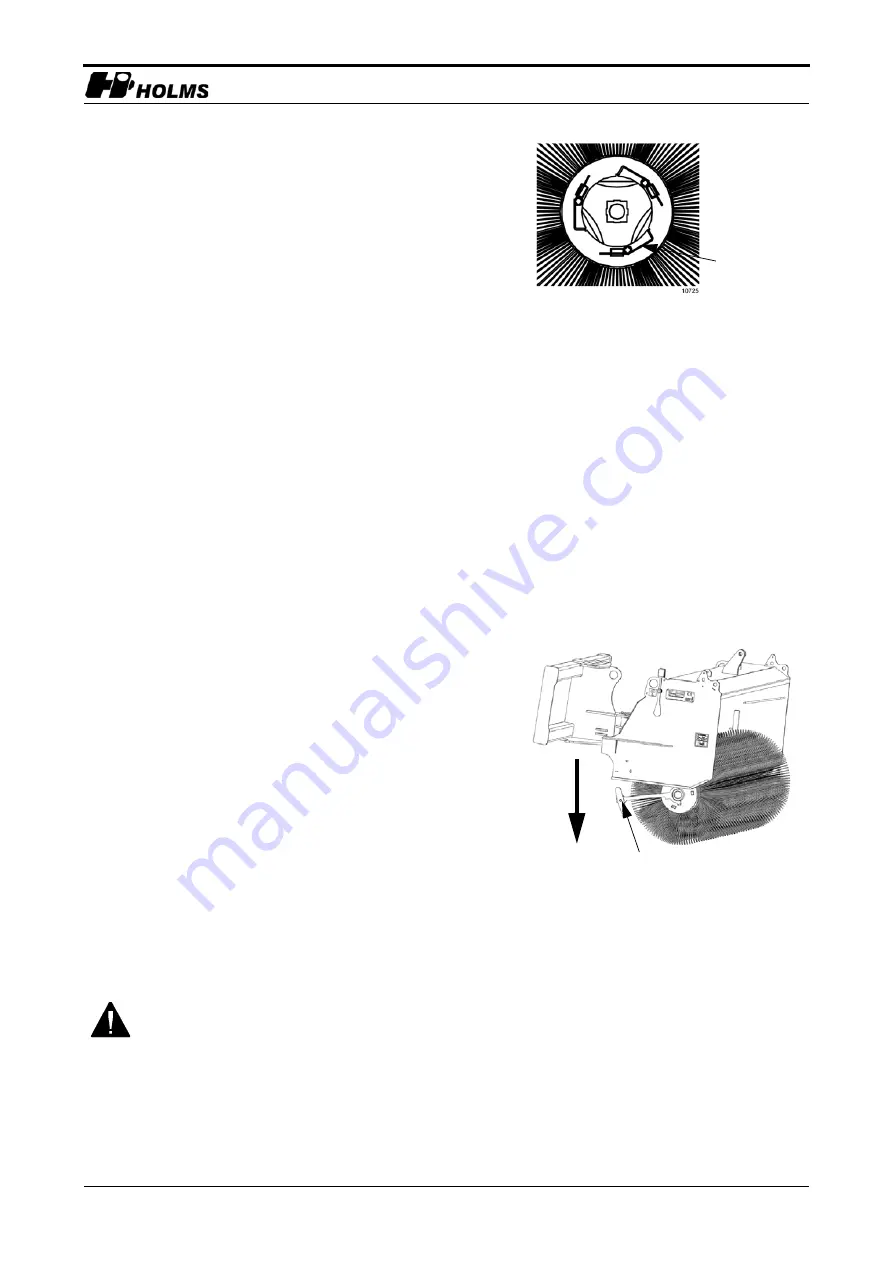

Replacing the brush

1. Release the three tension springs and remove the

roller brush’s end ring, see figure 19.

2. Pull off the brush and spacer rings. This is most easily

done by hanging up the roller vertically in an

overhead crane or suchlike.

3. Check the core for damage.

4. Lift up the brush core with the bearing shaft facing

downwards on a pair of wooden blocks or suchlike.

This is to prevent damaging the shaft and slewing

brackets.

5. Insert a brush using the brush ring's "pins" in the

space between the three square sections.

6. Fit a spacer ring.

7. Fit alternating brush rings and spacer rings. Please

note that the brush rings' “carrier pins” must be more

or less evenly divided between the three square

sections. This is so that no single section will be

exposed to all the strain from the brushes.

8. To “cover” the entire core it may be necessary to use

double brushes without spacer ring on the end so that

the right length will be obtained.

9. Refit the end ring using the three tension springs.

See figure 19.

Fitting the roller brush

1. Roll in the roller

2. Push the brush in towards the motor package in the

chassis.

3. Lift up the loose slewing bracket, figure 20 and fit it,

see B in figure 17 on page 18.

4. Lower the machine.

5. Re-attach the slewing bracket top, see A in figure 17

on page 18.

Always use Loctite on the screws.

19.Tension springs

Clamp plate for slewing brackets

20.Refitting the motor

Summary of Contents for DUO 1.50

Page 2: ......