5

J. KEEP THE WORK AREA WELL LIGHTED.

ALL ELECTRICAL CONNECTIONS SHALL BE

PERFORMED BY A LICENCED TECHNICIAN. ALL

SERVICE MUST BE PERFORMED BY AN AUTHORIZED

SERVICE TECHNICIAN.

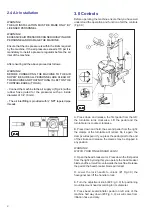

1.4 Nomenclature

Before installing and using the tire changer, it is suggested

that you become familiar with the nomenclature of the

machine’s components (Fig.1.0) :

1

Vertical slide

2

Swing arm

3

Adjustment knob

4

Lock lever

5

Mount/demount tool

6

Tower or column

7

Turntable

8

Jaw

9

Bead breaker arm

10

Bead breaker blade

11

Bead breaker pads

12

Foot pedal controls

13

Inflation gauge

14

Bead seater (Exept 1520m)/inflator pedal

15

Air jets (Exept 1520m)

16

Air tank (Exept 1520m)

1.5 Specifications

Electric-air tire changer for car, light commercial vehicle

and motorcycle tires designed for one-piece rims.

Outer clamping range (1520)

10 - 18”

Inner clamping range (1520)

12 - 20”

with motorcycle jaws (1520m)

15 - 21”

with special jaws for motor-scooter/ATV wheels (1520m) 7 - 15”

Bead breaking range - 1520

2 – 13”

Bead breaking range – 1520M

0,5 – 13”

Rim width

3 - 12” (3-10” for 1520m)

Overall wheel diameter

4 0 ”

Power supply:

Standard version

1–ph AC, 115 V, 60 Hz

Amp.

12A

Drive rating

1 HP

Compressed air supply

110-170 PSI

Noise level 70 dB(A)

1.6 Dimensions of the Machine

Max depth

43 ¾” (1110 mm)

Max depth (Bead Seater Ver.)

53 ½” (1360 mm)

Max width

42” (1050 mm)

Overall height

67 ¾” (1720 mm)

Approx weight

374,78 lbs (170 kg)

1.7 Standard Accessories

#0001418 Bead lifting tool

#0001419 Swab

287

1.0

1.0

1.0

1.0

1.0

294