34

monty 3550 / 3550AIR

USA - CANADA

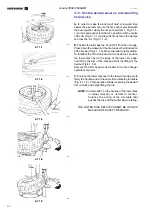

4.2-1

4.2-3

4.2-4

4.2.1-1

4.2-2

336.tif

338.tif

905.tif

930.tif

337.tif

4.2 Mounting tubeless tires

A.

Lubricate the entire rim surface (Fig. 4.2-1).

Lubricate both beads, inside and outside, (Fig. 4.2-2).

WARNING

LIBERAL LUBRICATION OF THE TIRE AND RIM IS

NECESSARY TO MOUNT TIRE CENTERING

CORRECTLY AND GET A PROPER ON THE RIM. BE

SURE YOU ARE USING APPROVED LUBRICANT

ONLY.

WARNING

OBSERVE THE ROTATION DIRECTION OF THE TIRE,

IF REQUIRED. SOME TIRES HAVE A COLOR DOT

THAT MUST BE KEPT ON THE OUTSIDE OF THE

WHEEL.

B.

Lock the rim on the turntable and rotate it to have the

valve in 5 o’clock position. Place the tire to be mounted on

the rim. Swing the mounting arm forward so that the mount/

demount tool is in the working position. Engage the lower

bead OVER the mounting wing and UNDER the mounting

finger of the mounting tool. Turn the wheel clockwise and

push the tire down into the drop center, opposite to the

mount/demount head (Fig. 4.2-3).

C.

Mount the upper bead following the directions in section

B (Fig. 4.2-4). With low profile tires the pneumatic bead

holding and mounting tool “Easymont Pro” - (optional

retrofit kit) can help to facilitate mounting of the top bead.

4.2.1 Use the bead presser as a mounting

help device.

A.

Mount the first bead.

Position the roller (Item 1) and the bead pusher tool (Item

2) as showed in Fig. 4.2.1-1.

B.

Lower the bead pusher so that the roller and the bead

pusher tool on the tire help keeping the bead into the drop

center (Fig. 4.2-4).

The bead pusher tool follows the tire rotation during the

mounting operation.

Bring the roller and the bead pusher tool back to rest

position.